Film for decoration and preparation method thereof

A film and film layer technology, applied in the field of decorative film and its preparation, can solve the problems of reduced productivity, complicated process, increased cost, etc., and achieve the effects of high productivity, simple process and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The raw materials used in the following examples are shown in the table below.

[0052] Product grade

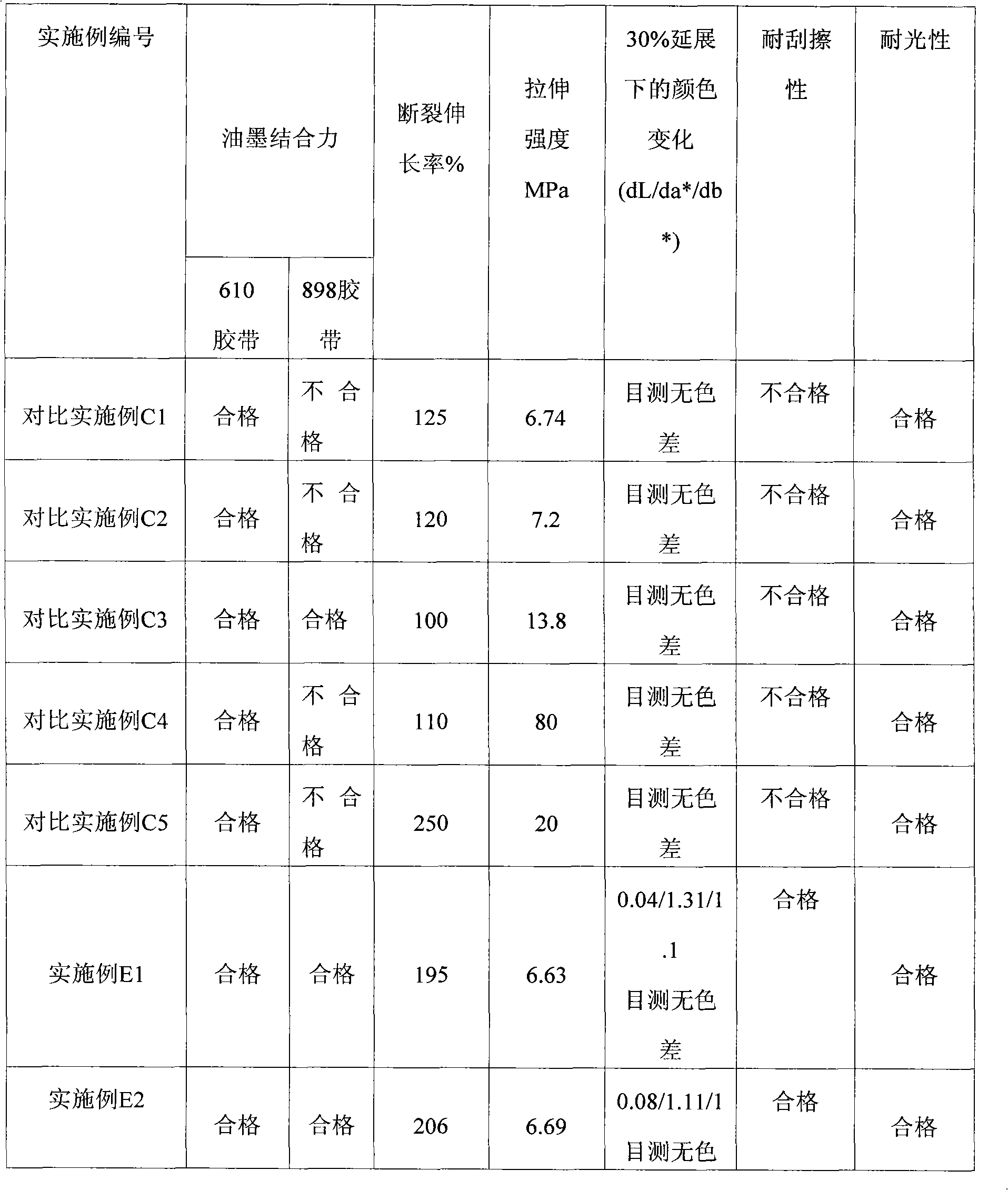

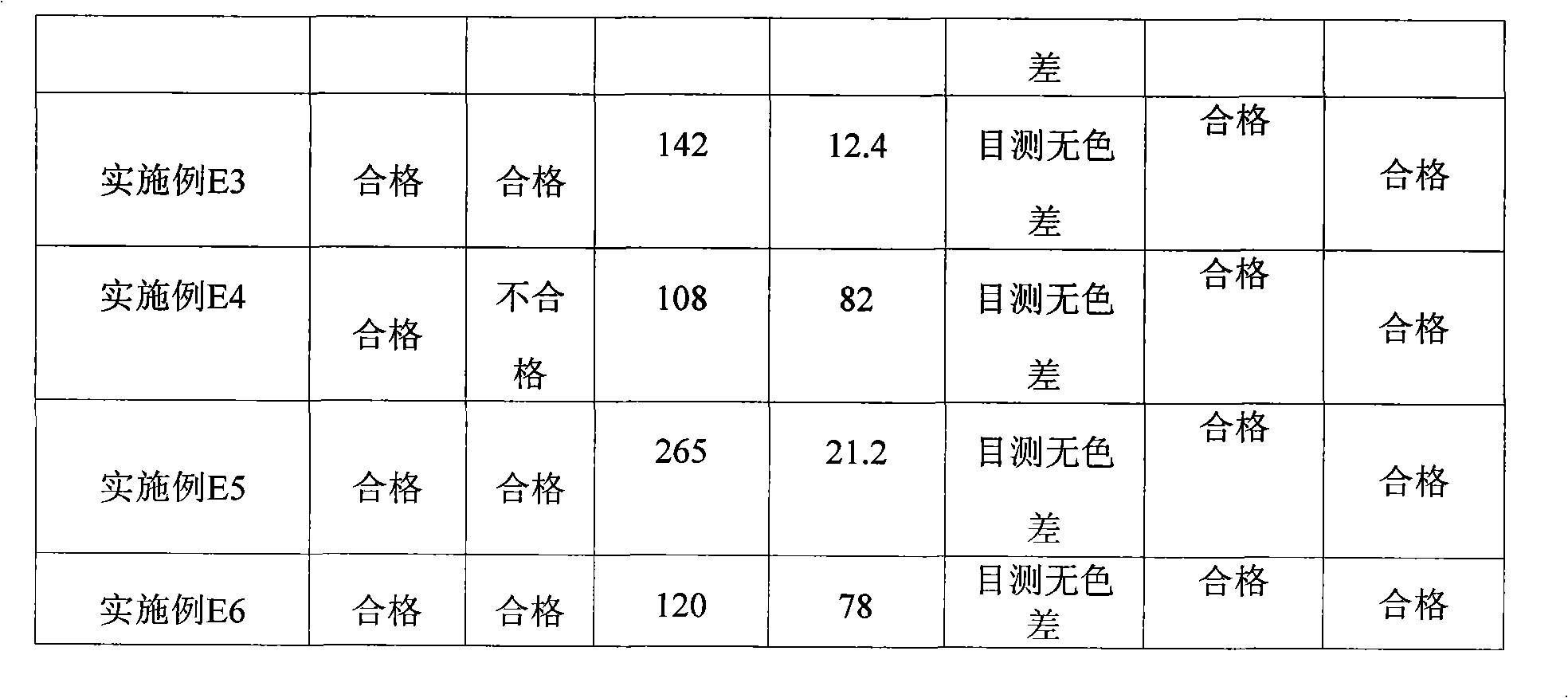

Embodiment E1

[0069] Use the R940 printing machine to print on the back of the 18069 transparent polyvinyl chloride film with a thickness of 50 μm, the ink brand is TFG ink, the thickness of the printing layer is controlled at 10 μm, the production speed of the printing machine is 100m / min, and the oven temperature is 40°C. PVC film samples;

[0070] Mix 100g of CSA3075 glue and 0.4g of RD1054 cross-linking agent, evenly spread on the release paper of SCW27, control the coating thickness of the glue film after drying to 25μm, and place it in an oven at 120°C for about 3 minutes;

[0071] The printed surface of the color film is bonded to the glued surface to obtain a finished colored polyvinyl chloride film.

Embodiment E2

[0073] Use the R940 printing machine to print on the back of the 18069 transparent polyvinyl chloride film with a thickness of 50 μm, the ink brand is TFG ink, the thickness of the printing layer is controlled at 10 μm, the production speed of the printing machine is 100m / min, and the oven temperature is 40°C. PVC film samples;

[0074] Mix 100g of CSA3075 glue and 0.4g of RD1054 cross-linking agent, and evenly spread it on the release paper of SCW27, control the coating thickness of the glue film to be 30μm after drying, and place it in an oven at 120°C for about 3 minutes;

[0075] The printed surface of the color film is bonded to the glued surface to obtain a finished colored polyvinyl chloride film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com