Automatic car positioning device of roller machine tool

An automatic positioning, roller bed technology, applied in workpiece clamping devices, transportation and packaging, conveyor objects, etc., can solve problems such as reducing the efficiency of robot spraying, increasing the labor intensity of on-site personnel, and not completely solving the precise positioning of the body. Achieve the effect of improving body positioning efficiency, reducing labor input costs, high positioning accuracy and spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

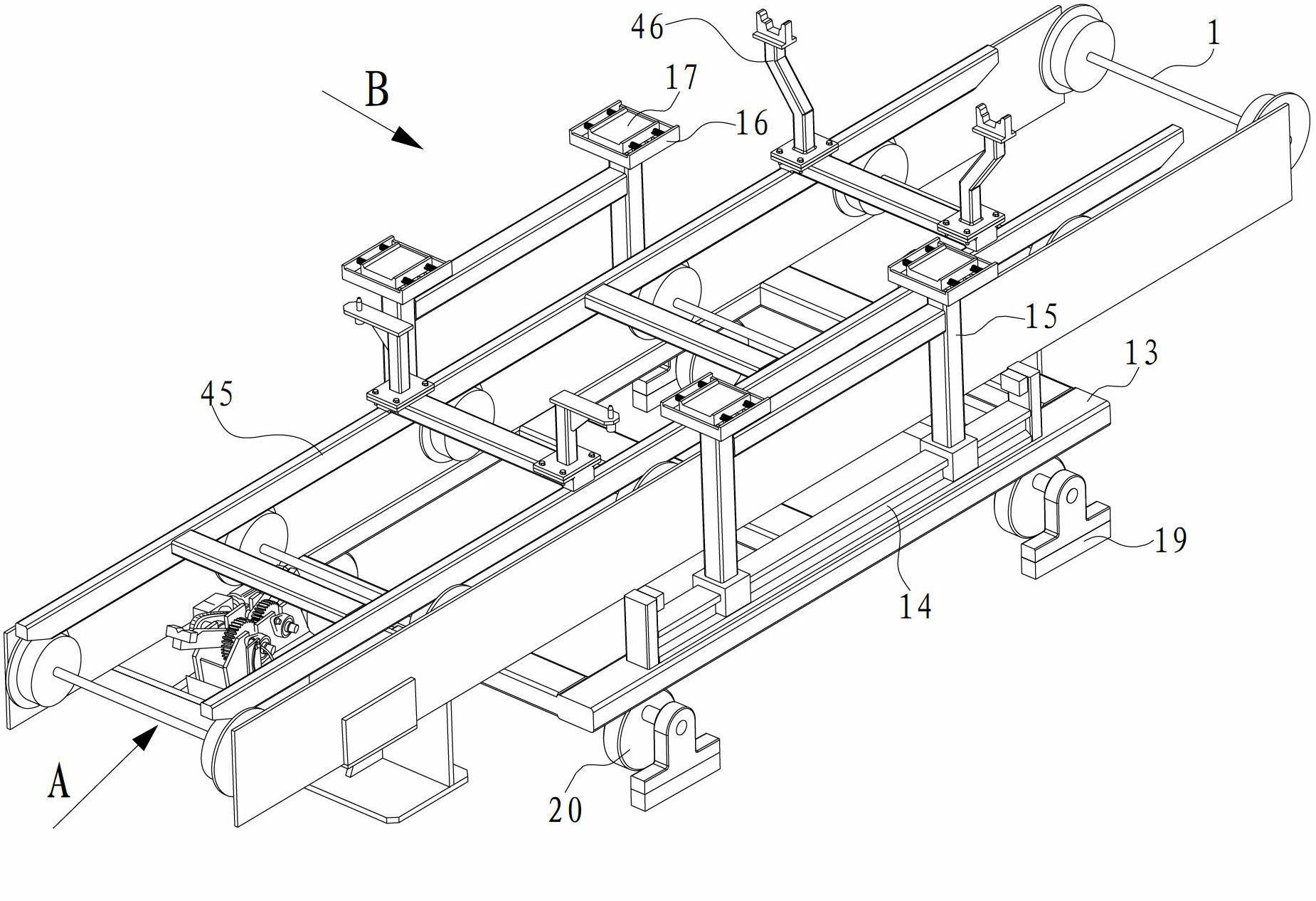

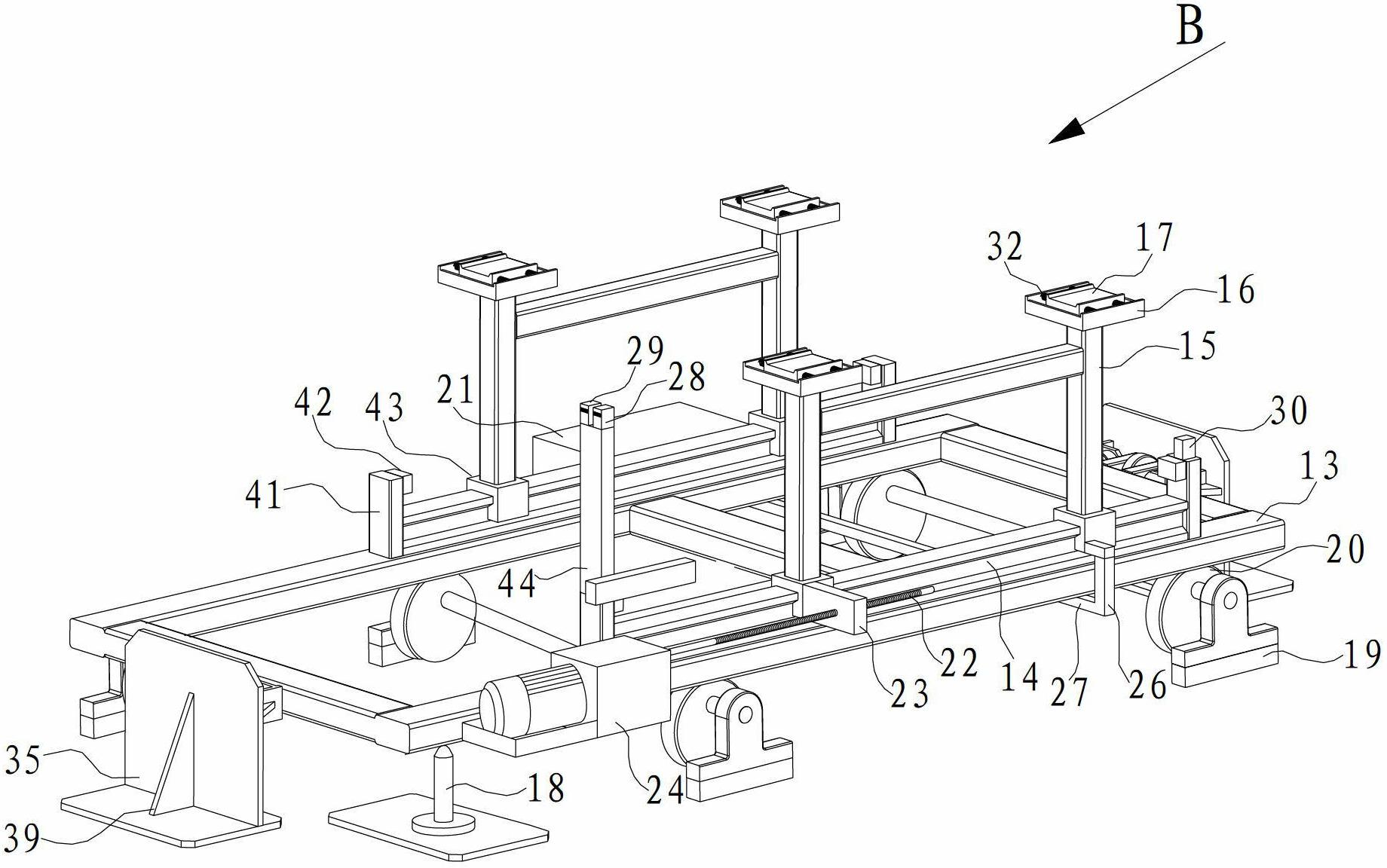

[0036] Such as Figure 1-3 As shown, a vehicle body automatic positioning device on a roller bed includes a roller bed 1, a skid 45 slidingly matched with the roller bed 1, a vehicle body positioning mechanism 46 fixed on the skid, and a mounting seat fixed on the roller bed 1. Skid clamping mechanism A and body adjustment device B.

[0037] figure 1 The specific structure of the middle skid clamping mechanism A and the body adjustment device B is omitted, and the detailed structure is shown in the partial enlarged view figure 2 and image 3 .

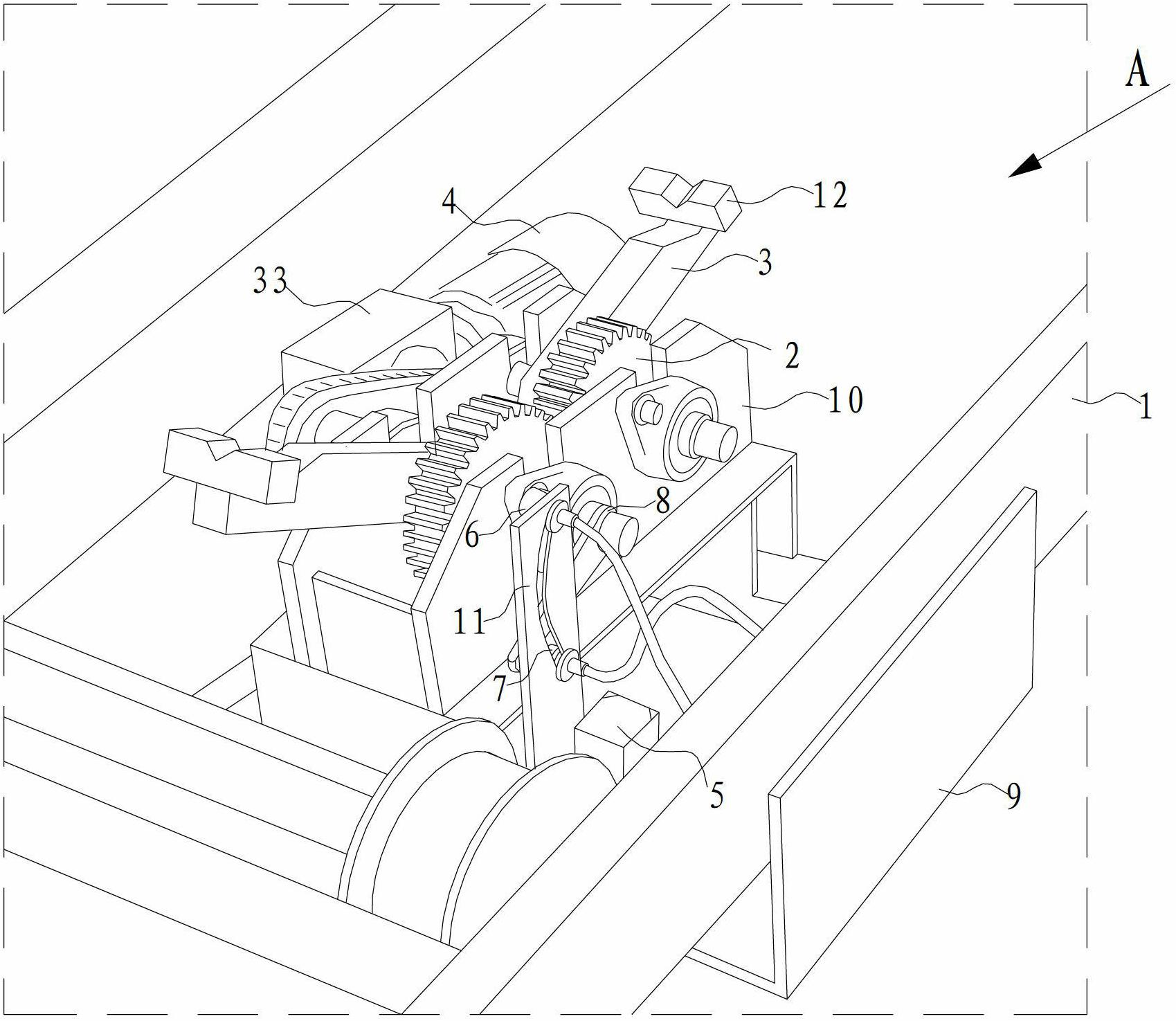

[0038] Such as figure 2 As shown, the specific structure of the skid clamping mechanism A is as follows:

[0039] The skid clamping mechanism A includes two gears 2 meshing with each other, a clamping mechanism motor 4 that drives the gears 2 to rotate, and a clamping arm 3 that is respectively fixed on the rotating shafts of the two gears 2 and arranged opposite to each other. The clamping mechanism motor 4 It is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com