Extreme-pressure abrasion-resistant open gear oil

An extreme-pressure anti-wear agent and grinding-opening technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of high production cost and insufficient anti-wear performance, so as to ensure adhesion and improve extreme pressure resistance. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

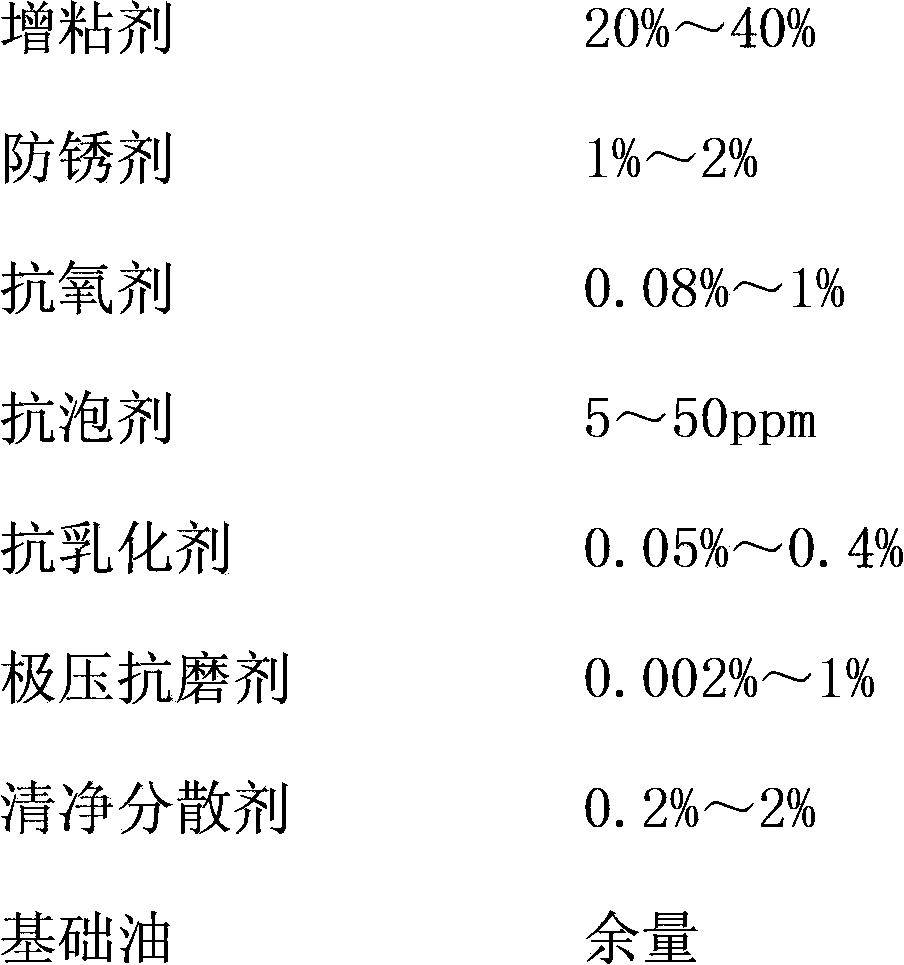

Method used

Image

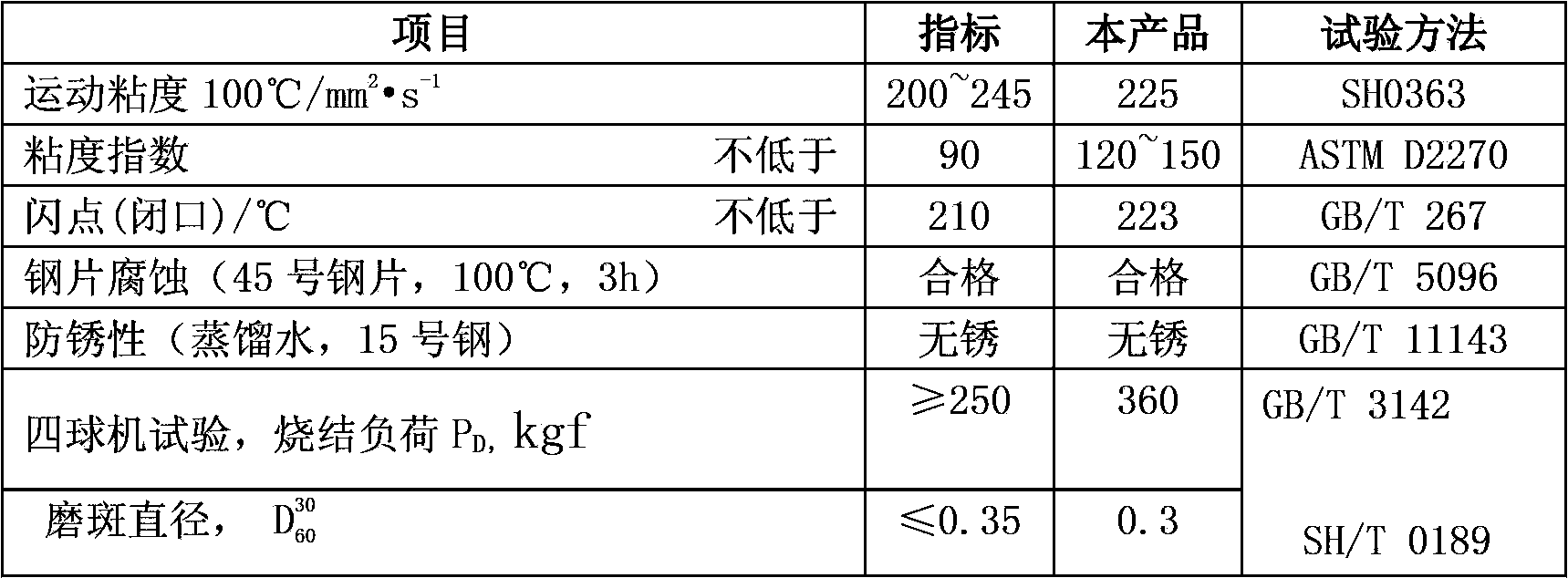

Examples

Embodiment 1

[0025] The present invention adopts the following components by weight: 25% of tackifier polyisobutylene, 1% of antirust agent benzotriazole derivative, 0.1% of antioxidant 2,6-di-tert-butyl p-cresol, anti-gun agent T901 Base silicone oil 5ppm, anti-emulsifier amine and ethylene oxide condensate 0.4%, extreme pressure and anti-wear agent nano-graphene 0.5%, cleansing and dispersing agent alkylbenzene high alkali value synthetic calcium sulfonate 0.2%, the balance is mineral oil .

[0026] Preparation method and steps of the present invention are as follows:

[0027] First, prepare nano-graphene powder by the Hummer method, then add the prepared nano-graphene powder and base oil into the base oil according to the ratio (1%~5%), place it in a planetary ball mill for 48 hours, and use the base oil Dilute the oil containing 1%~5% of nano-graphene to the required concentration of nano-carbon powder to 0.5%, and then add the above-mentioned other additives in proportion. The oil i...

Embodiment 2

[0029] The present invention adopts the following composition by weight: tackifier polymethacrylate 20%, antirust agent benzotriazole derivative 1.2%, antioxidant 2,6-di-tert-butylphenol 0.08%, antifoam Agent polysiloxane 10ppm, anti-emulsifier ethylene oxide propylene oxide copolymer 0.05%, extreme pressure and anti-wear agent nano-graphene 0.002%, detergent and dispersant hexenyl bisstearamide 0.5%, and the balance is mineral Oil.

[0030] Preparation method and steps of the present invention are as follows:

[0031] Firstly, the nano-graphene powder was prepared by the Hummer method, and then the prepared nano-graphene powder was added to the base oil according to the ratio (1%~5%) of the base oil, and placed in a planetary ball mill for treatment48. Use base oil to dilute the oil containing 1%~5% of nano-graphene to the required concentration of 0.002% of nano-carbon powder, and then add the above-mentioned other additives in proportion. The oil is placed in a strong ult...

Embodiment 3

[0033] The present invention adopts the following components by weight: tackifier hydrogenated styrene diene copolymer 32%, antirust agent thiadiazole derivative 2%, antioxidant tetrakis[β-(3,5-di-tert-butyl- 4-hydroxyphenyl) propionate] pentaerythritol ester 1%, polyether antifoam agent 25ppm, anti-emulsifier polyoxypropylene derivative D114 0.2%, extreme pressure antiwear agent 0.5%, detergent and dispersant stearin 2% monoglyceride and the balance is mineral oil.

[0034] Preparation method and steps of the present invention are as follows:

[0035] Firstly, the nano-graphene powder was prepared by the Humer method, and then the prepared nano-graphene powder was added to the base oil according to the proportion (1%~5%) of the base oil, and placed in a planetary ball mill for 48 hours. Use base oil to dilute the oil containing 1%~5% of nano-graphene to the required concentration of 0.5% of nano-carbon powder, and then add the above-mentioned other additives in proportion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com