Specified spiral photocatalysis sewage treatment equipment

A technology for sewage treatment and special equipment, which is applied in illumination water/sewage treatment, oxidized water/sewage treatment, special compound water treatment, etc., and can solve the problem of short photocatalytic distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

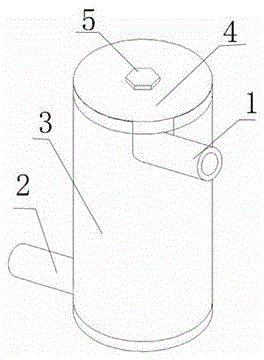

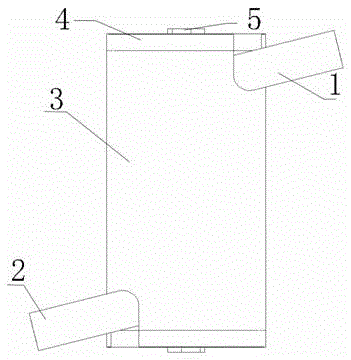

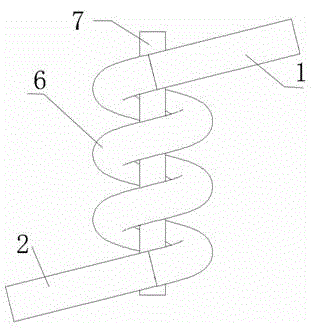

[0022] A spiral photocatalytic sewage treatment special equipment, comprising a pipe body 3, end caps 4 screwed on both ends of the pipe body 3, a spiral glass tube 6 is arranged inside the pipe body 3, the water inlet 1 and the water outlet 2 of the spiral glass tube 6 Lead out through the opening 8 provided on the tube body 3, the center of the spiral glass tube 6 is provided with a lamp tube 7, the inner wall of the tube body 3 is a glass reflective surface 31, the spiral glass tube 6 is provided with activated carbon, and TiO2 is attached to the activated carbon . The inner wall of the tube body 3 adopts a glass reflective surface, so that the light emitted by the lamp tube 7 passes through the gaps between the spiral glass tubes 6 and is reflected to the backlight surface of the spiral glass tube 6, increasing the irradiated surface of the spiral glass tube and improving the efficiency. The end cap 4 is provided with a hexagonal nut 5 . Easy removal of end caps. The di...

Embodiment 2

[0025] A spiral type special equipment for photocatalytic sewage treatment, comprising a pipe body 3, end caps 4 screwed on both ends of the pipe body 3, a spiral plexiglass tube 6 is arranged inside the pipe body 3, the water inlet 1 and the outlet of the spiral plexiglass tube 6 The nozzle 2 is led out through the opening 8 provided on the tube body 3, the center of the spiral plexiglass tube 6 is provided with a lamp tube 7, the inner wall of the tube body 3 is a glass reflective surface 31, and the spiral plexiglass tube 6 is provided with activated carbon, activated carbon TiO2 is attached to it. The inner wall of the tube body 3 adopts a glass reflective surface, so that the light emitted by the lamp tube 7 passes through the gap between the spiral plexiglass tubes 6 and then reflects to the backlight surface of the spiral plexiglass tube 6, increasing the irradiated surface of the spiral plexiglass tube) , which improves the efficiency. The end cap 4 is provided with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com