Waste lye treatment method, carbon black reduction method and device thereof

A treatment method and technology for treatment devices, which are applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve equipment corrosion, low stable operation rate of carbon black water system, and high carbon black output To reduce the workload, improve the oxidative combustion effect, and improve the smooth running rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

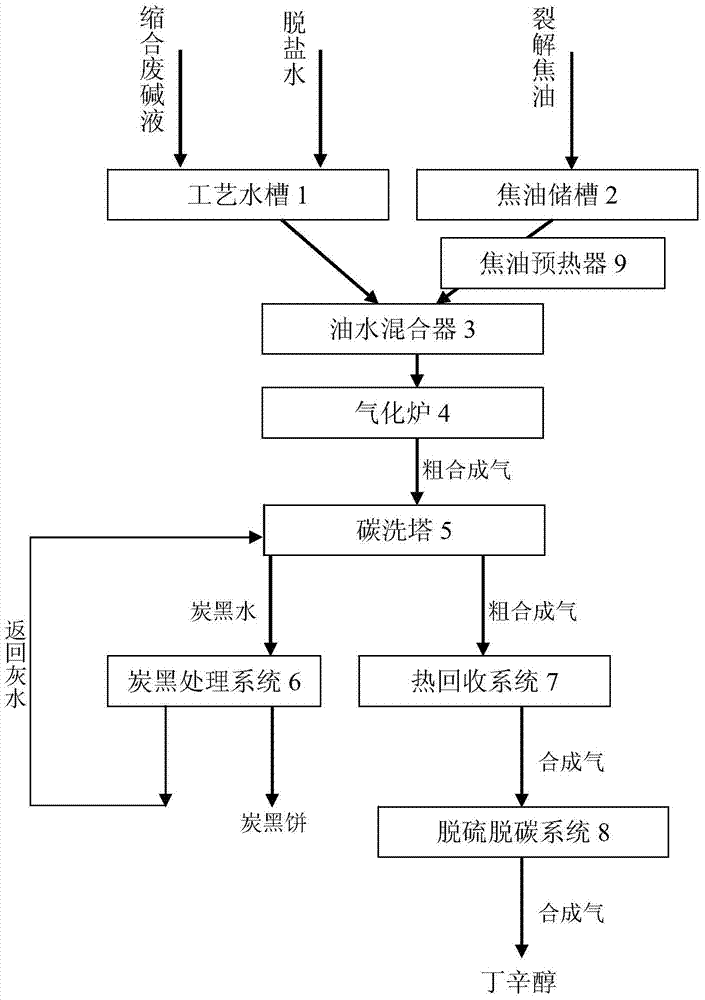

[0084] Such as figure 1 As shown, it is a schematic diagram of the technological process of adding waste lye to process water, and then performing partial oxidation reaction and refining.

[0085] exist figure 1 Including: process water tank 1, tar storage tank 2, oil-water mixer 3, gasifier 4, carbon washing tower 5, carbon black treatment system 6, heat recovery system 7, desulfurization and decarbonization system 8 and tar preheater 9 , these constituent units together constitute a syngas plant, and after the condensation waste caustic liquor participates in the gasification reaction in the gasifier 4 of the syngas plant, the amount of by-product carbon black in the syngas plant is reduced.

[0086] Process water tank 1 is a container for storing process water of gasification raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com