Method for preparing security paper with window and watermark

A technology of anti-counterfeiting paper and windows, applied in textiles and papermaking, papermaking, papermaking and other directions, can solve the problems of easy forgery and achieve the effect of artistic, effective compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a kind of anti-counterfeiting paper with a window in the shape of a pentagram and a watermark, which is prepared through the following steps:

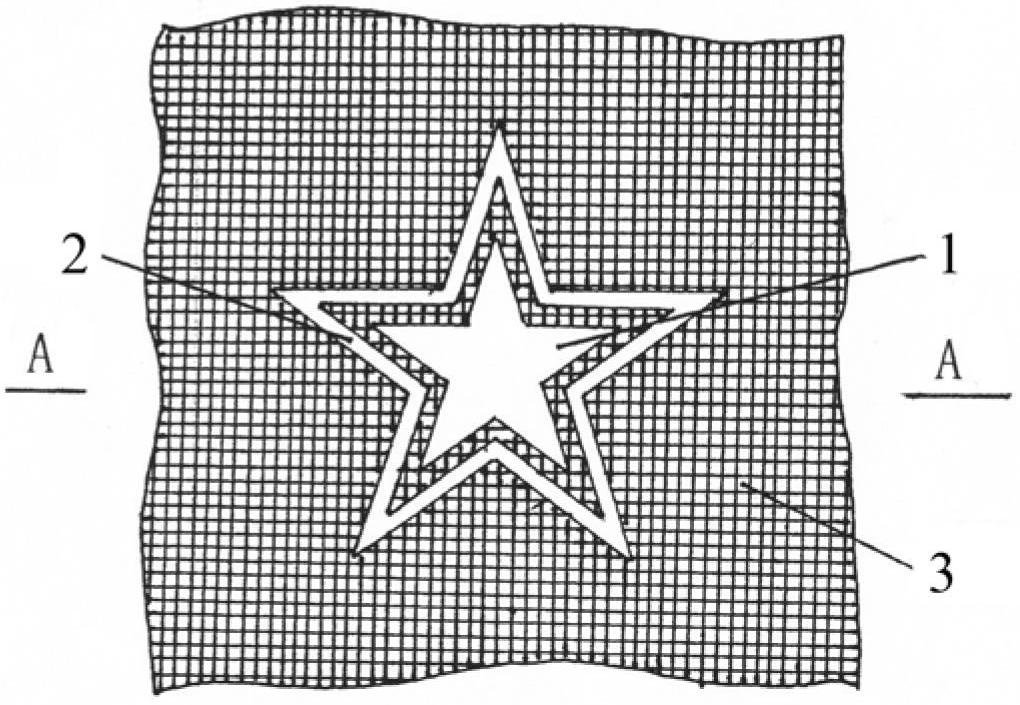

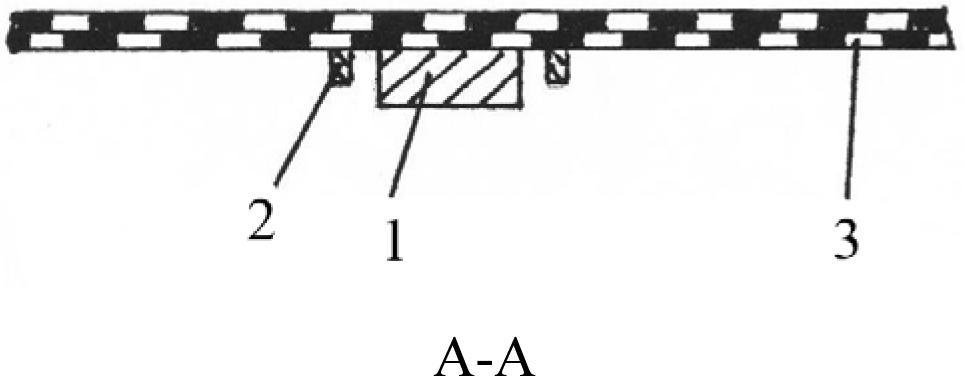

[0042] Prepare a mold in the shape of a five-pointed star. On the mold, the middle part is a window part 1 in the shape of a five-pointed star, and its material is a copper sheet. The material is copper sheet, which is welded on the surface net 3 and made into a mesh cage, such as figure 1 As shown, its cross-section is as figure 2 shown;

[0043] Hoist the cage to the rotary paper machine for papermaking to obtain a wet paper sheet with a five-pointed star-shaped window;

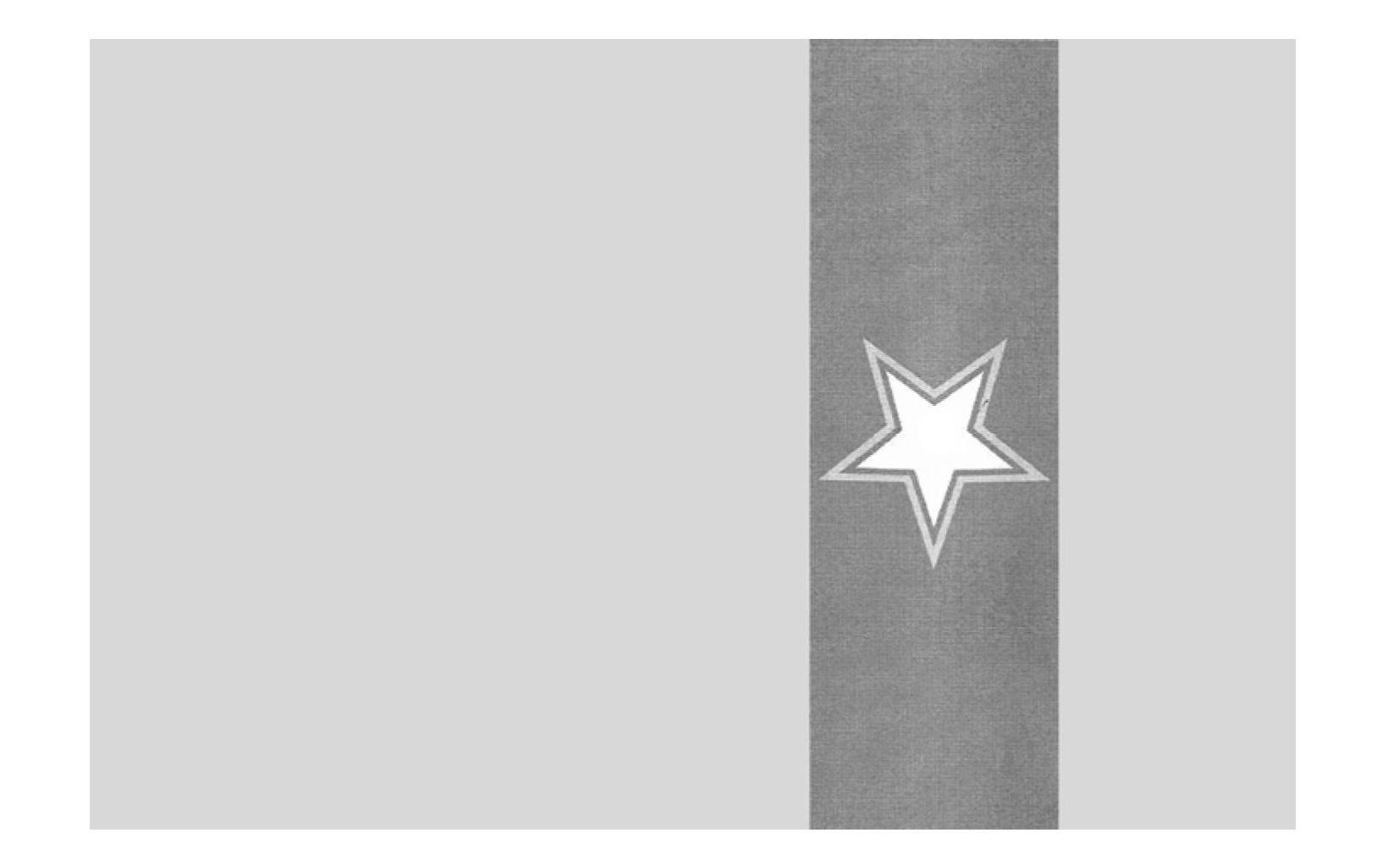

[0044] Composite a layer of holographic film 7 to the middle of two layers of wet paper sheets with windows, which can cover the area with windows, to obtain composite wet paper sheets, press and dry the composite wet paper sheets to obtain dry paper sheets, Promptly obtain the anti-counterfeiting paper with the window of five-poi...

Embodiment 2

[0047] This embodiment provides an anti-counterfeit paper with a clover-shaped window and a watermark, which is prepared through the following steps:

[0048] A clover-shaped die is prepared, on which the middle part is a clover-shaped window part 1 made of copper sheet, and there is a circle of clover-shaped and slightly lower watermark part 2 on the outside of which is made of copper sheet , weld the mold piece on the surface net 3, and make a cage, such as Figure 5 As shown, its cross-section is as Image 6 shown;

[0049] Hoist the net cage to the paper machine for papermaking to obtain a wet paper sheet with a clover-shaped window;

[0050] Lay a layer of fluorescent film on one side of a layer of wet paper with a window, just enough to cover the area with the window, and then use a short former to stick a thinner layer on the side with the fluorescent film Pulp, this layer of pulp only covers the edge part of the fluorescent film and the area on the wet paper sheet w...

Embodiment 3

[0053] This embodiment provides a kind of anti-counterfeiting paper with a window in the shape of an ancient coin and a watermark, which is prepared through the following steps:

[0054] A mold of an ancient coin is prepared. On the mold, the middle part is a window part 1 in the shape of a square hole, and its material is a copper sheet. The outer edge of the square hole is a part of the watermark part 2, and the outer circumference of the ancient coin is also a watermark. As part of part 2, the watermark part 2 is made of copper sheet, and in the area between the above two parts, there is another half of the area as the second watermark part 9, which is made of copper mesh;

[0055] The die is welded on the surface net 3, and made into a mesh cage, such as Figure 8 As shown, its cross-section is as Figure 9 shown;

[0056] Hoist the net cage to the paper machine for copying to obtain wet paper pages with windows and watermarks, wherein the windows and watermarks form the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap