High-geostress dam foundation excavation construction technology

A construction technology and high ground stress technology, which is applied in basic structure engineering, excavation, and testing of basic structures, etc., can solve the problems of delay in construction period, damage and destruction of unloading adjustment, long construction time interval, etc., to save construction period and Construction cost, good economic benefits, and the effect of avoiding secondary excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

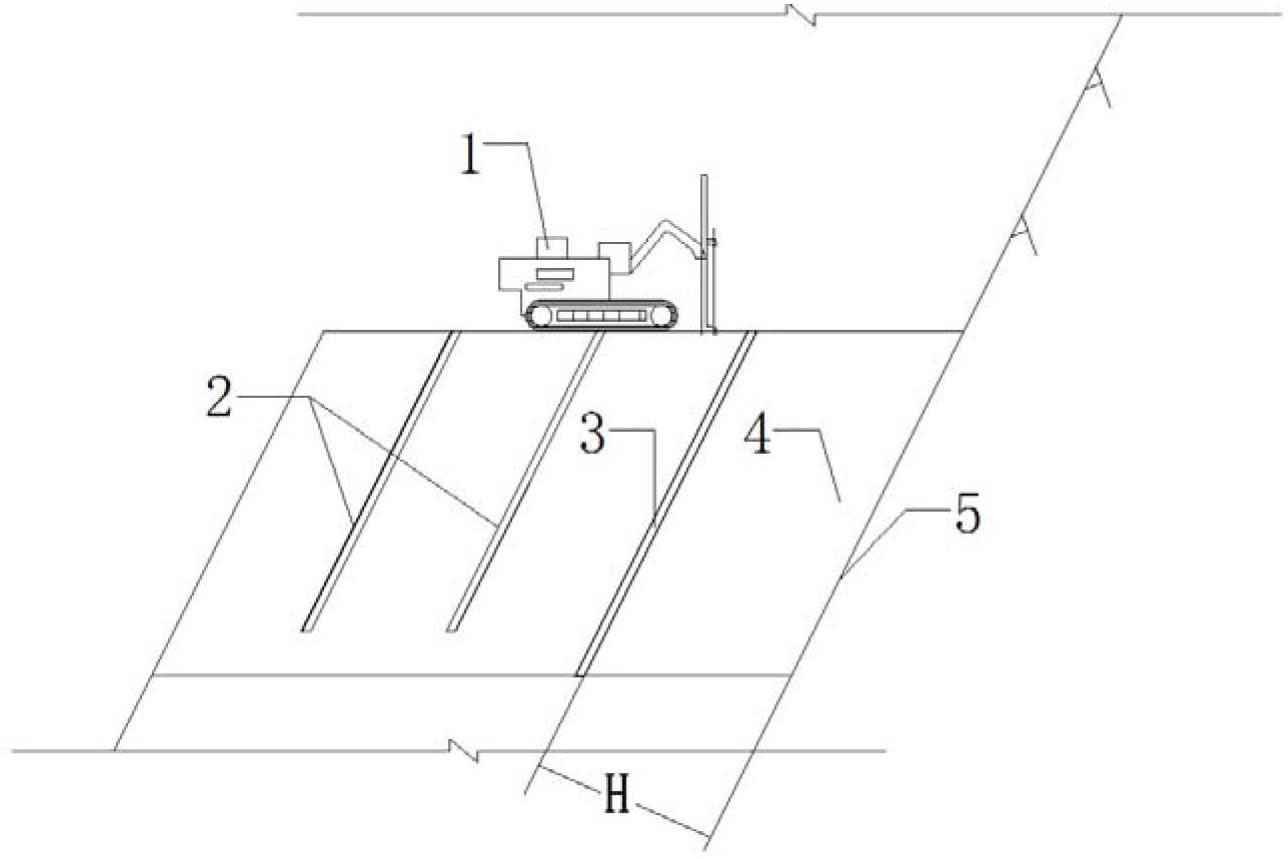

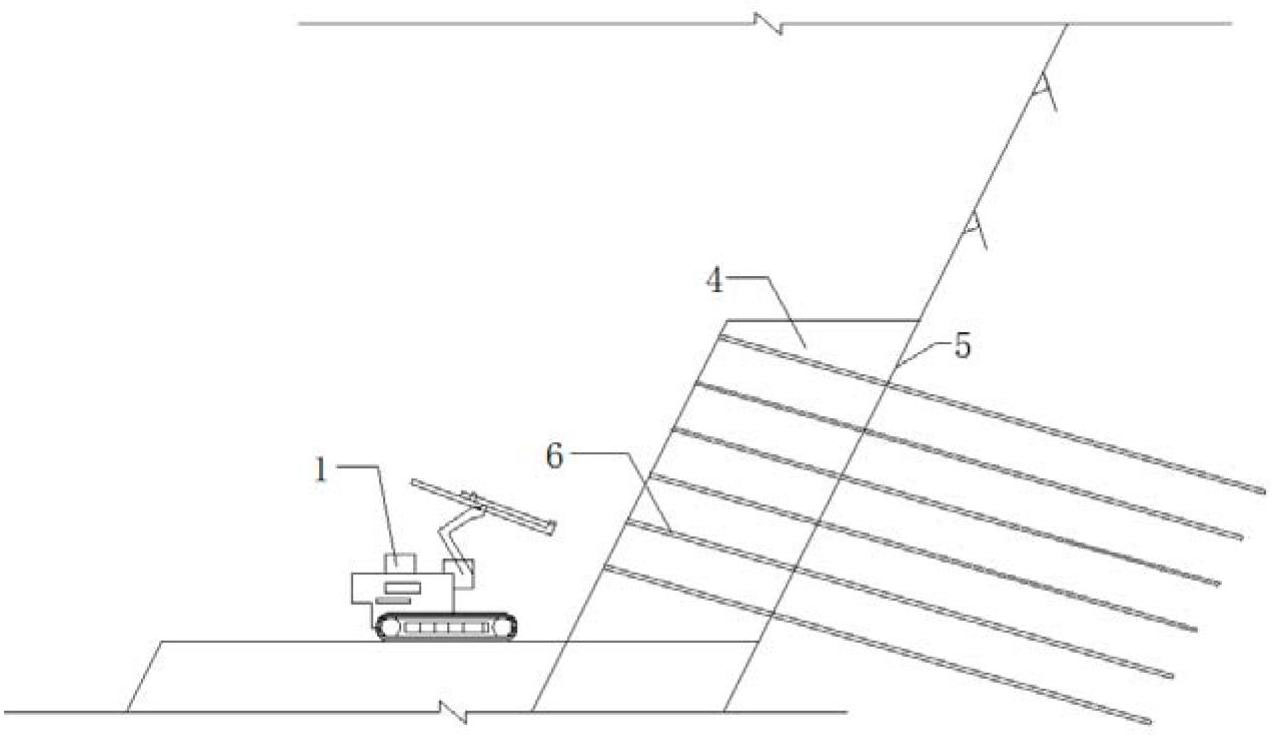

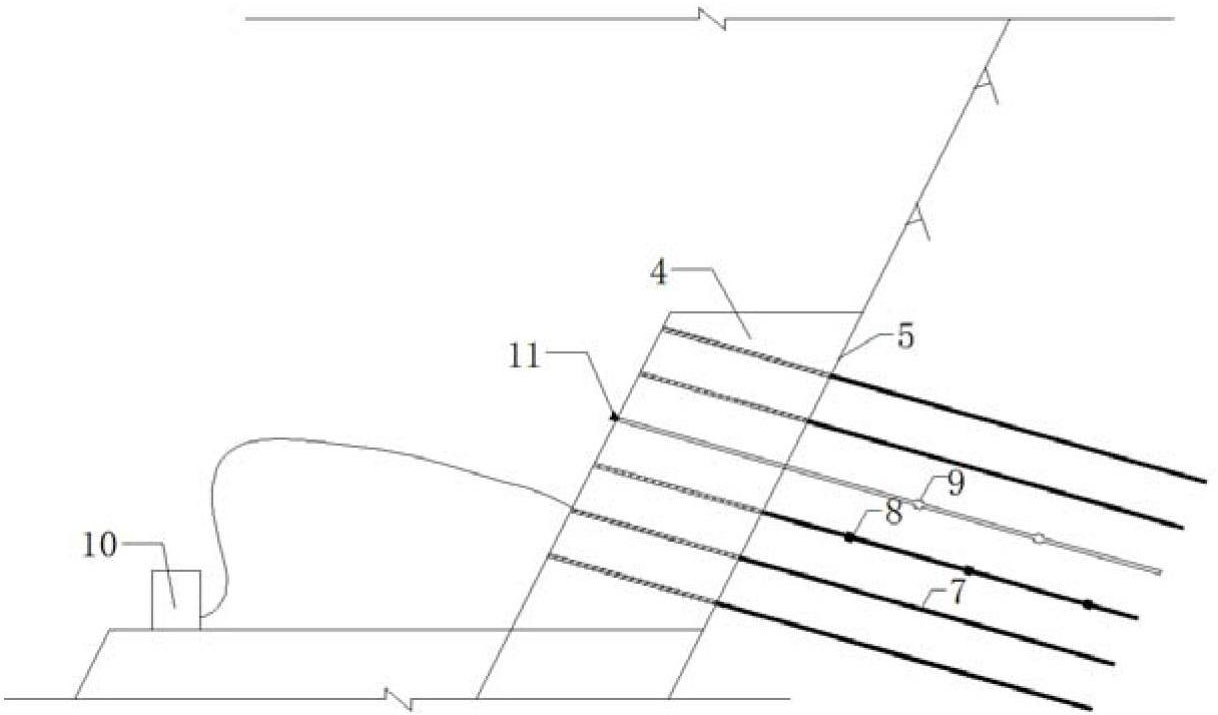

[0022] combine Figure 1 to Figure 5 .

[0023] The excavation construction technology of high ground stress dam foundation includes the following steps:

[0024] A. Pre-cracking and excavation on the outside of the dam foundation protective layer. The drilling equipment 1 drills the blast hole 2 and the pre-split hole 3 in the outer area of the dam foundation protective layer 4. A dam foundation protective layer 4 with an appropriate thickness is reserved outside the base surface 5; the thickness H of the dam foundation protective layer 4 is 25 to 40 times the diameter of the charge at the bottom of the blast hole in the step, forming the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com