Hydraulic control valve device

A hydraulic control valve, control valve technology, applied in fluid pressure actuators, servo motors, servo meter circuits, etc., can solve the problems of high coordination, low efficiency, wide bandwidth, etc., achieve stable adjustment characteristics, avoid vibration problems, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

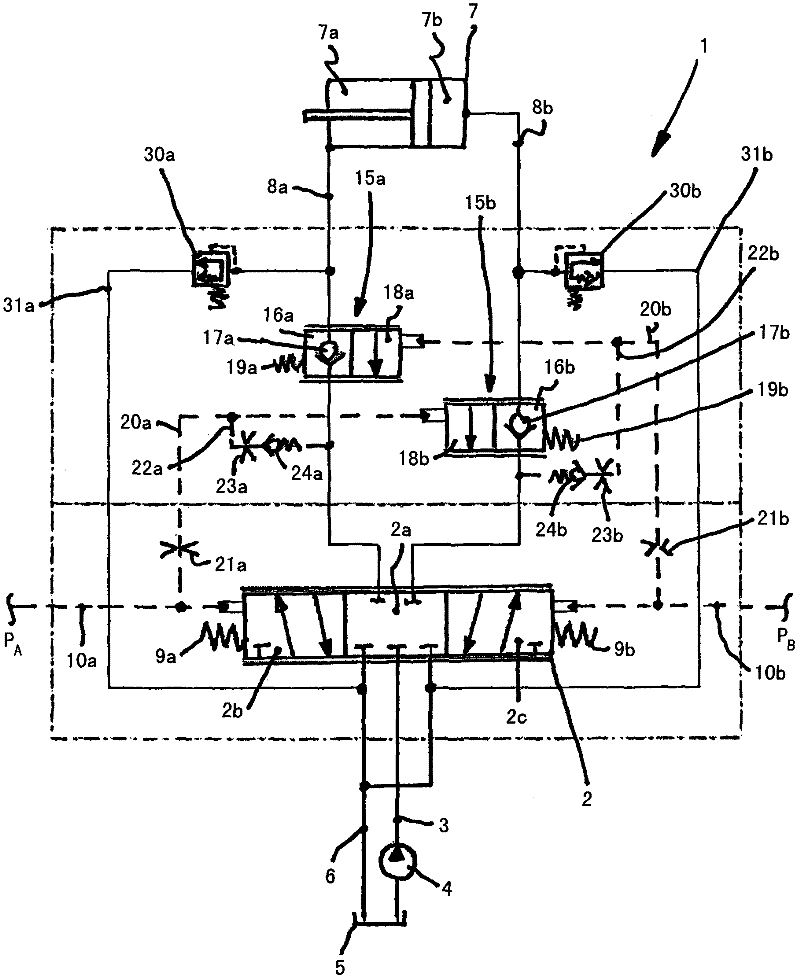

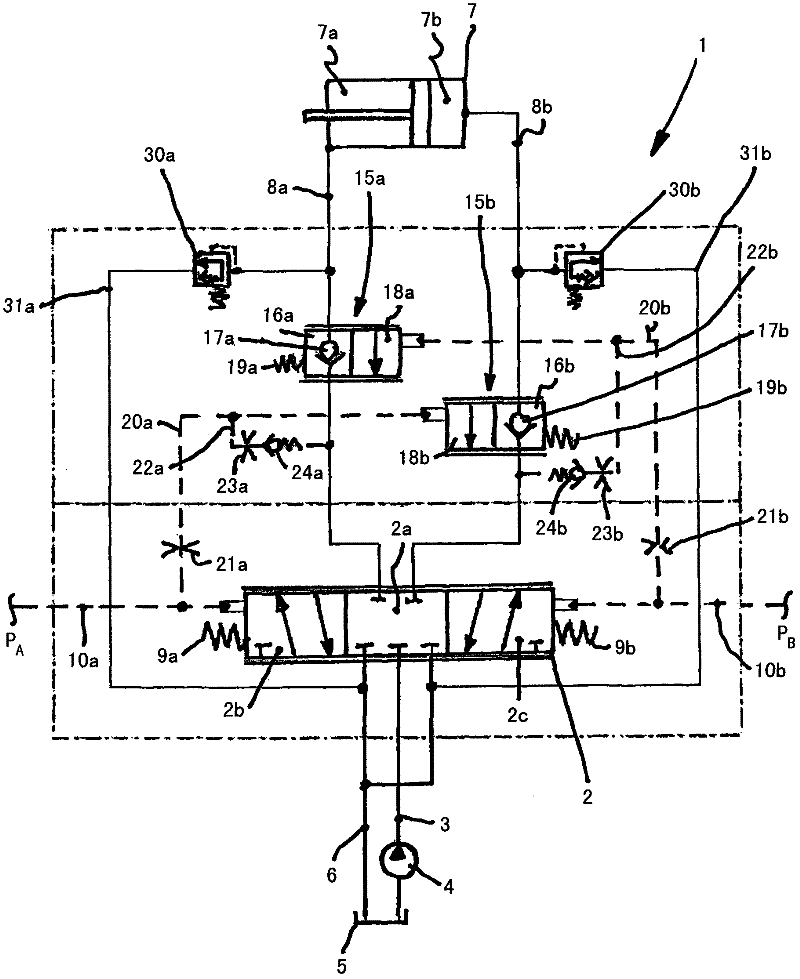

[0013] The control valve arrangement 1 comprises a control valve 2 configured as a directional control valve throttled in an intermediate position, which is connected to the delivery line 3 of a pump 4 operated in an open circuit and to a container 5 On the container pipeline 6.

[0014] The control valve 2 controls the direction of movement and the speed of movement of the double-acting hydraulic cylinder 7, wherein the control valve 2 is connected to the first pressure chamber 7a of the hydraulic cylinder 7 by means of a first consumer line 8a and by means of The second consumer line 8b is connected to the second pressure chamber 7b of the hydraulic cylinder 7 .

[0015] The control valve 2 has a blocking position 2 a configured as a neutral position, in which the connection of the consumer lines 8 a , 8 b to the delivery line 3 and the container line 6 is blocked. In the first control position 2 b of the control valve 2 , the first consumer line 8 a is connected to the del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com