Method for operating a gas turbine below the nominal power thereof

A gas turbine, rated power technology, applied in the direction of gas turbine devices, combustion control, mechanical equipment, etc., can solve the problems of reducing the efficiency of gas turbines, achieve stable adjustment characteristics, improve efficiency, and avoid the effects of temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

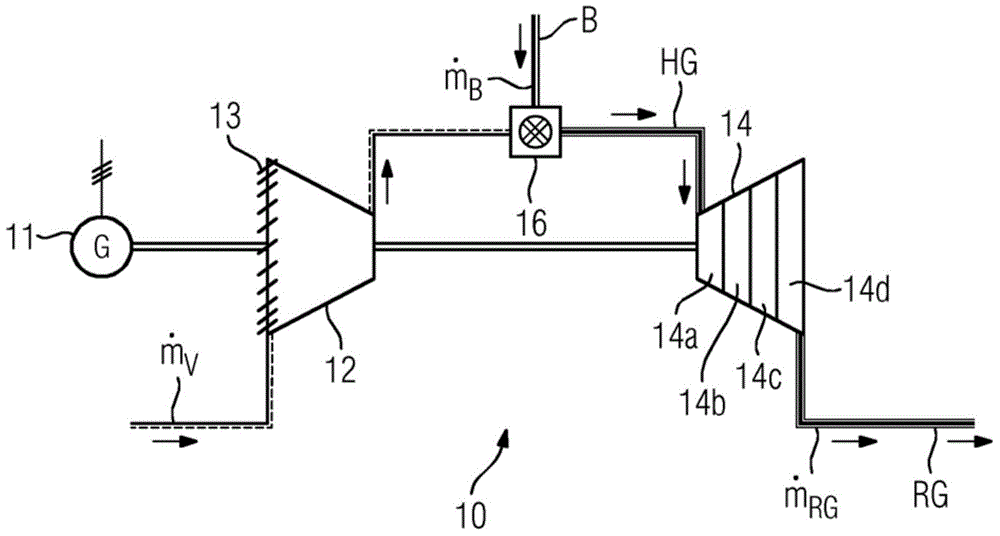

[0024] figure 1 A stationary gas turbine 10 is shown schematically with a compressor 12 and a turbine unit 14 , the rotor of which is rigidly coupled to the rotor of compressor 12 . A combustion chamber 16 is provided between the compressor output and the turbine unit 14 . The combustion chamber can be designed as a circular combustion chamber, as a tubular combustion chamber or as an annular combustion chamber. In the case of tubular combustors, there are usually 10, 12 or more tubular combustors. Also coupled to the compressor rotor is a generator 11 for generating electric current. At the inlet of the compressor 12 there are compressor inlet guide vanes 13 which are pivotable about their longitudinal axis, by means of which guide vanes 13 the compressor mass flow m can be adjusted V . These guide vanes 13 are only shown schematically. The turbine unit 14 comprises according to this embodiment 4 successive turbine stages 14 a 、14 b 、14 c and 14 d , which are likewis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com