Concrete crack detector with reinforcing bar as electrode

A crack detector and concrete technology, applied in the direction of material impedance, etc., can solve problems such as the incompatibility of concrete, and achieve the effects of avoiding catastrophic damage, convenient construction and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

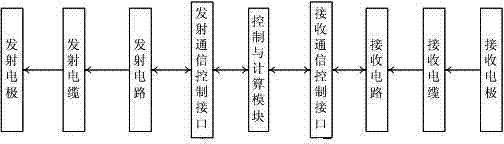

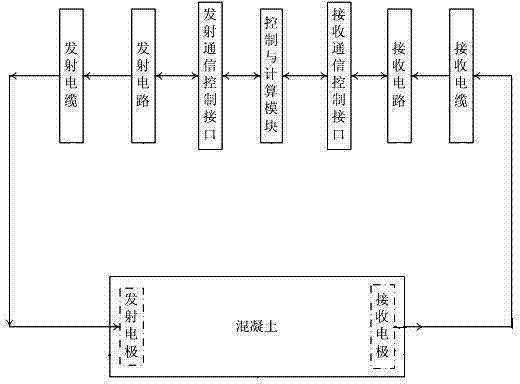

[0036] The detector is composed of a transmitting electrode, a transmitting cable, a transmitting circuit, a transmitting communication control interface, a control and calculation module, a receiving communication control interface, a receiving circuit, a receiving cable, and a receiving electrode. The transmitting electrode is connected to the transmitting circuit through the transmitting cable, the signal of the transmitting circuit is sent by the transmitting electrode, the receiving electrode is connected to the receiving circuit through the receiving cable, and the receiving circuit amplifies and filters the signal received by the receiving electrode. The transmitting circuit is connected to the control and calculation module through the transmission communication control interface, and the two-way communication control between the control and calculation module and the transmitting circuit. The receiving circuit is connected to the control and calculation module through ...

Embodiment 2

[0050] Both the transmitting electrode and the receiving electrode are ring electrodes, and the electrodes are buried in the concrete when the concrete is poured. The transmitting cable is connected to B1 and B2 of the transmitting electrode, and the receiving cable is connected to B1 and B2 of the receiving electrode. The analog signal output by the waveform generator of the transmitting circuit is directly output to the control and computing module through the transmitting communication and control interface. The single-chip microcomputer of the receiving circuit is connected to the amplification and filtering circuit through the IO pin, and the analog signal is directly transmitted to the control and calculation module after controlling the amplification and filtering circuit through the IO pin. The communication interface of the transmitting circuit and the receiving circuit adopts a parallel communication interface. The microprocessor chip contained in the control and ca...

Embodiment 3

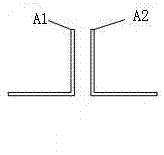

[0052] The transmitting electrode adopts dual steel bar electrode, and the receiving electrode adopts annular steel bar electrode. The electrodes are embedded in the concrete when the concrete is poured. The transmitting cable is connected to A1 and A2 of the transmitting electrode, and the receiving cable is connected to B1 and B2 of the receiving electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com