Light source-mask mixed optimizing method based on Abbe vector imaging model

A technology of imaging model and optimization method, which is applied in the direction of photo-plate making process of originals, optics, and pattern surface for photomechanical processing, and can solve the problem of affecting the optimization effect of light source and mask pattern, large deviation, and no consideration of projection system Issues such as differences in the response of incident light to light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

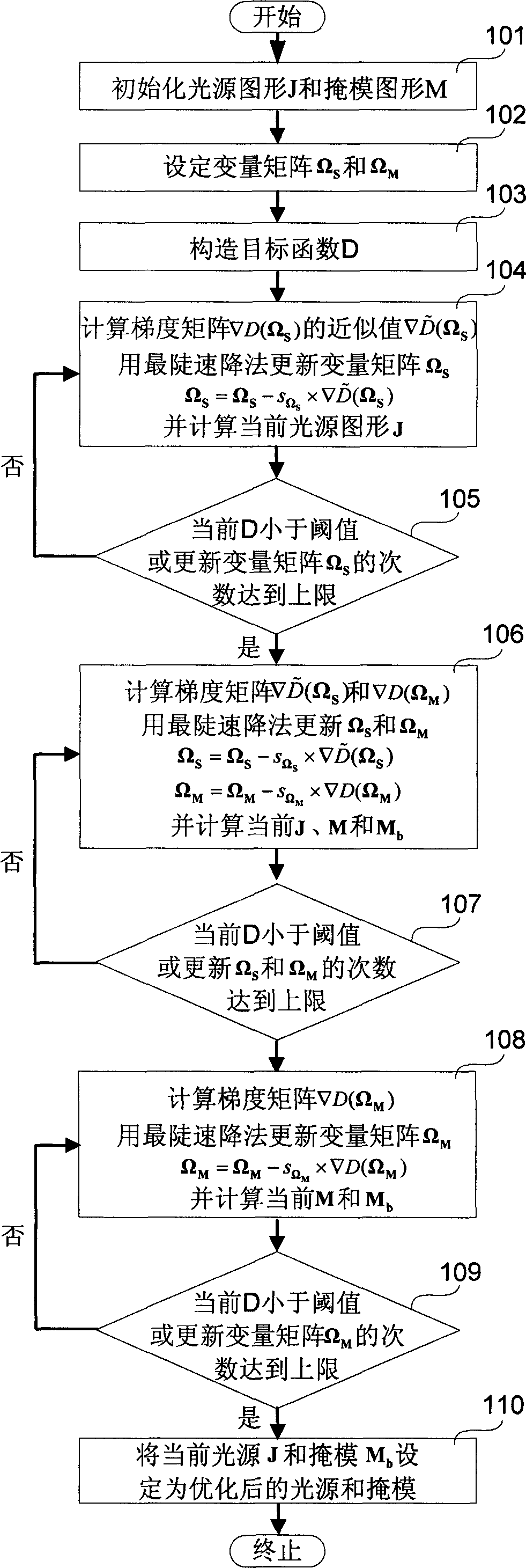

Method used

Image

Examples

Embodiment

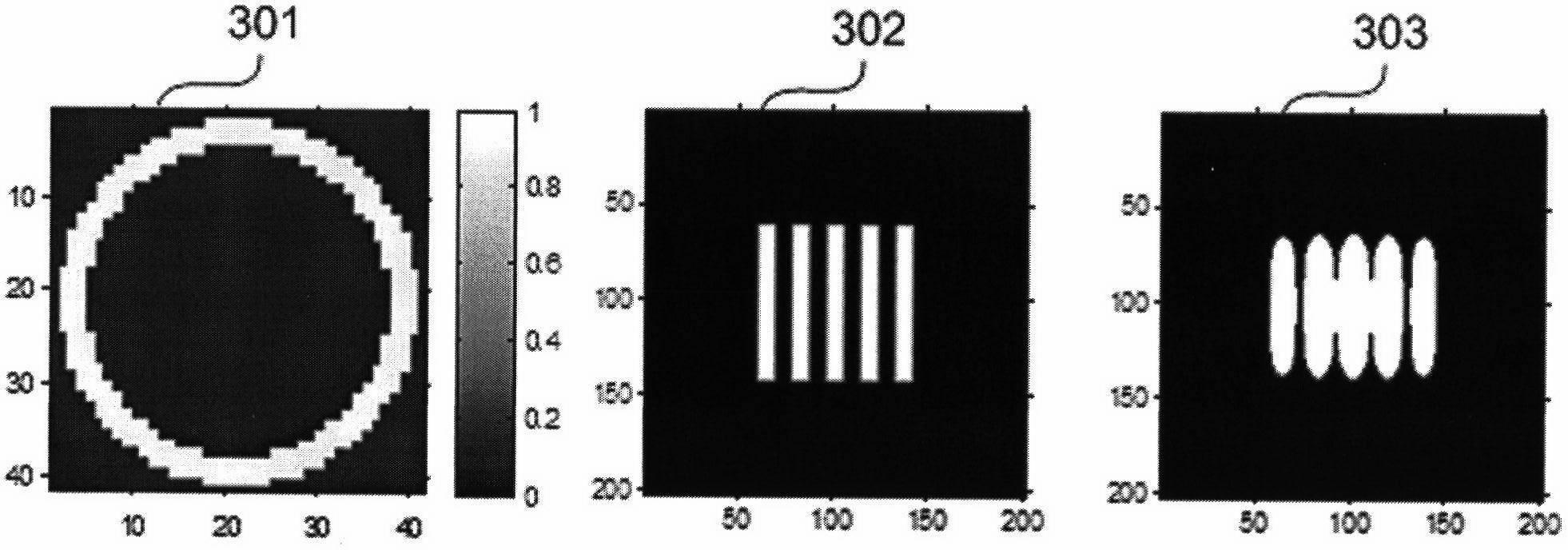

[0167] Such as image 3 Shown is a schematic of the initial light source, the initial mask and its corresponding imaging in the photoresist. 301 is the initial light source pattern, white represents the luminous part, and black represents the non-luminous part. 302 is the initial mask pattern, which is also the target pattern, white represents the opening part, black represents the light blocking part, and its critical dimension is 45nm. 303 is imaging in the photoresist of the photolithography system after using 301 as the light source and 302 as the mask, and the imaging error is 2286 (here, the imaging error is defined as the value of the objective function).

[0168] Such as Figure 4 Shown is a schematic diagram of the individual optimization results of the light source based on the Abbe vector imaging model, the initial mask pattern and its corresponding imaging in the photoresist. 401 is the individual optimization result of the light source based on the Abbe vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com