Method capable of simultaneously producing enamelled wires within large specification range in small scale and production line thereof

An enameled wire and production line technology, applied in the direction of electrical components, circuits, conductor/cable insulation, etc., can solve the problems of unable to solve customer order quantity, large size difference, and small order quantity, so as to avoid queuing test and acceptance storage, The effect of easy cleaning and small order quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

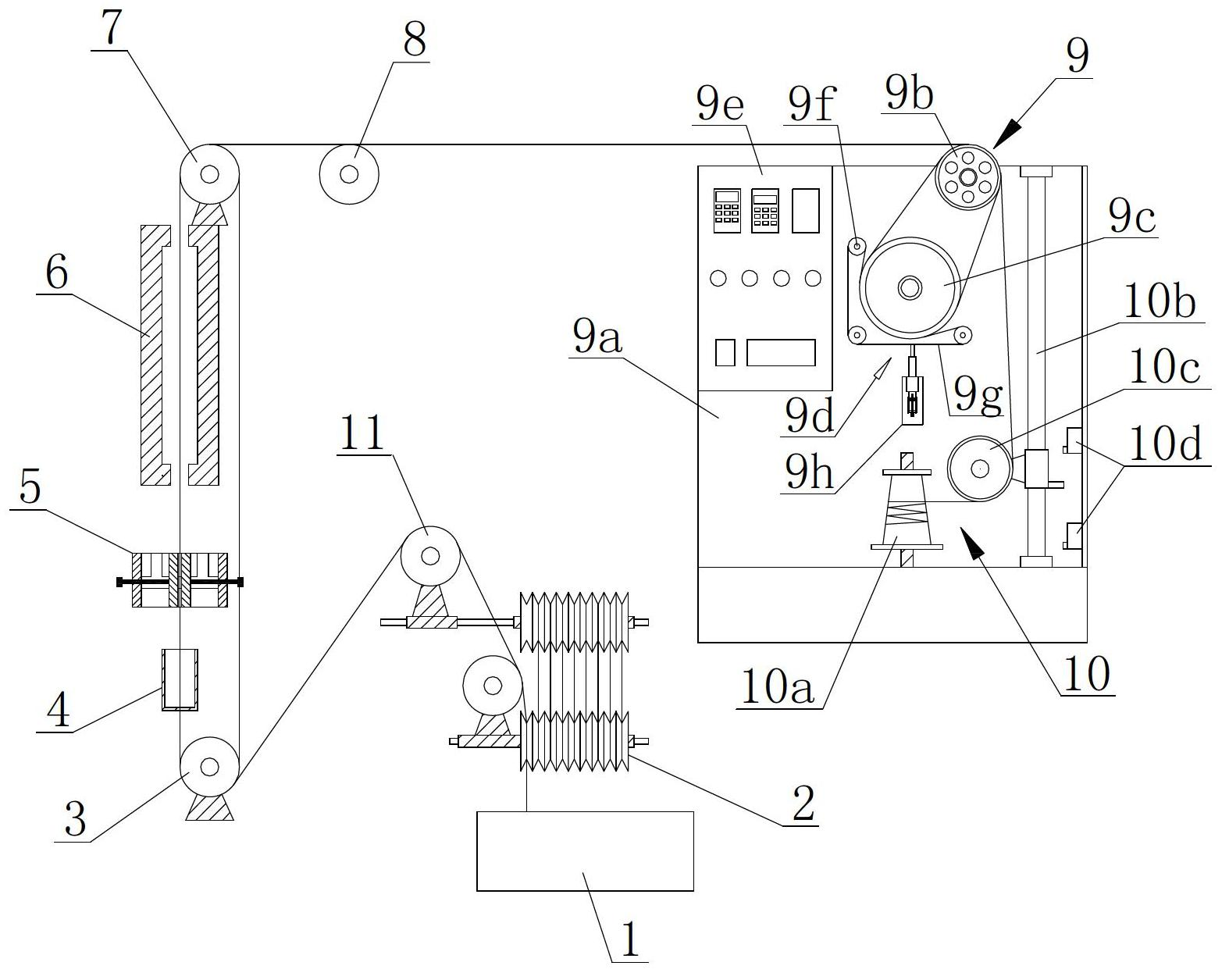

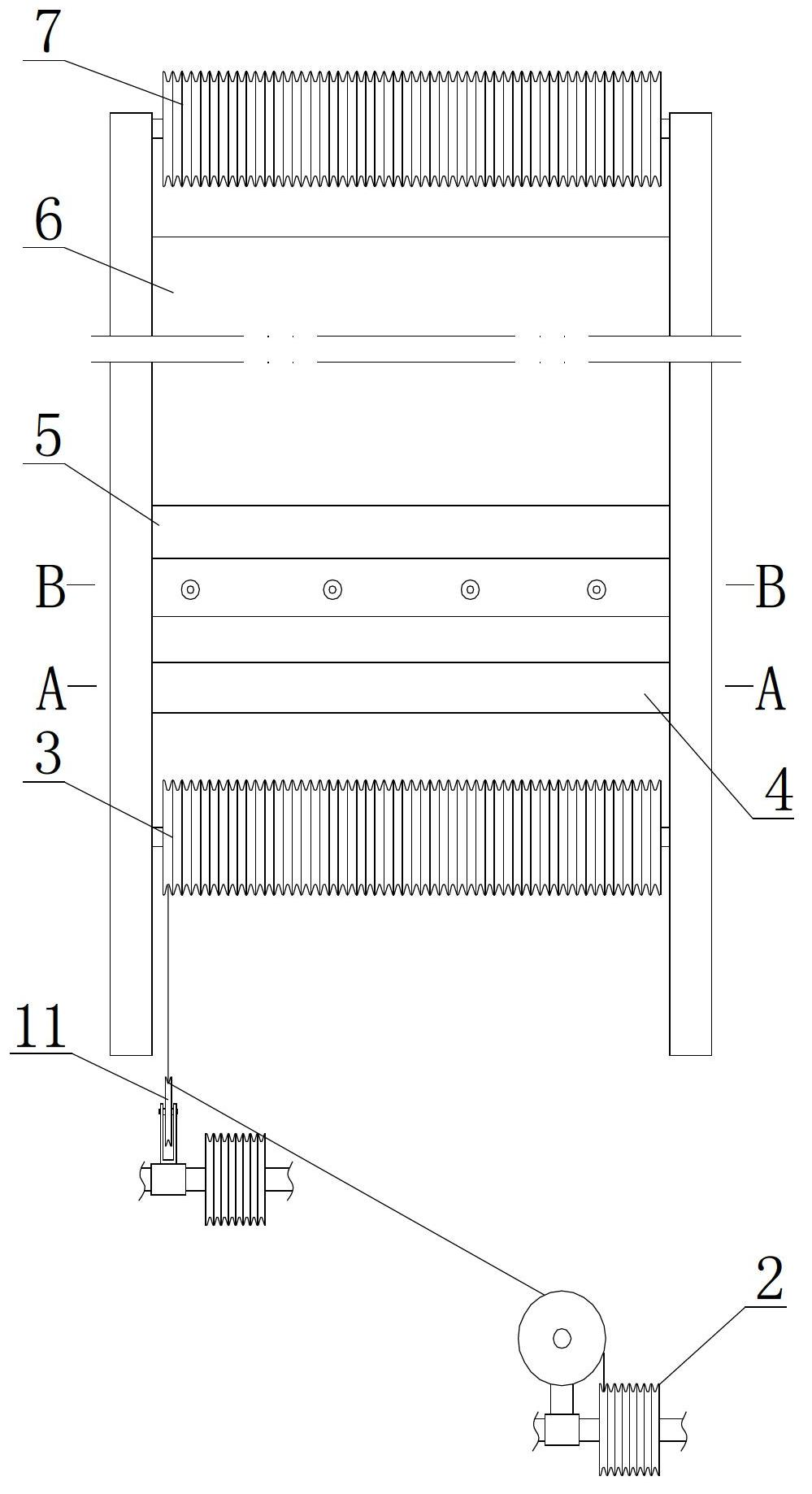

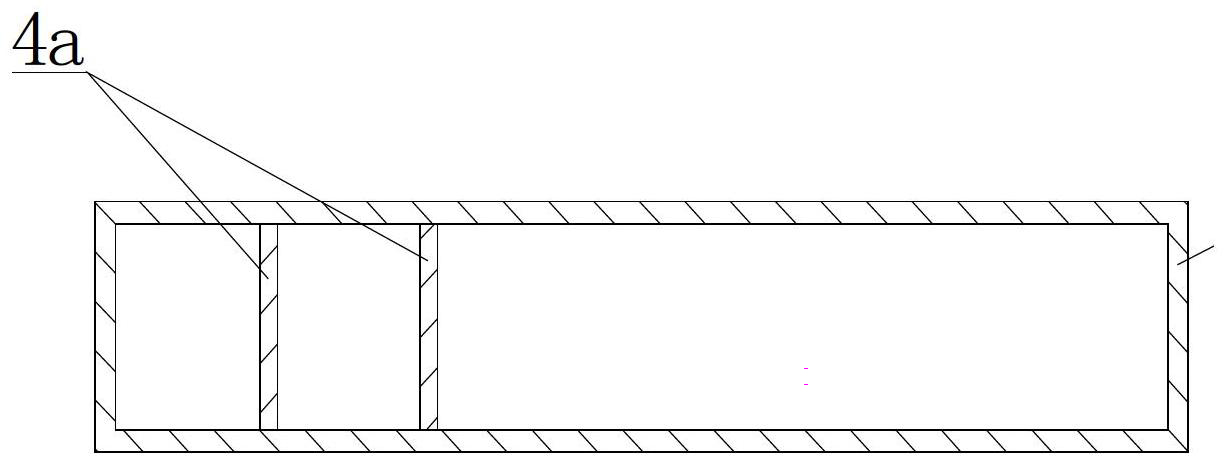

[0038] refer to Figure 1 to Figure 6 As shown, a production line of the present invention that can produce enameled wires with large size difference in a small amount at the same time includes an annealing furnace 1, an incoming line splitting guide wheel 2, a belt line lower guide wheel 3, a paint storage tank 4, a coating Painted felt clamp frame 5, paint baking oven 6, belt line guide wheel 7, outgoing line splitting guide wheel 8, the first traction device and the first wire take-up device, the first traction device and the first wire take-up device are existing There are original devices in the vertical enamelling machine production line. The first traction device and the first wire take-up device are set on the same frame, and the multiple traction wheels on the first traction device and the various pulleys are controlled by the same electronic control device. The wire tray corresponding to the traction pulley works; the rightmost wire groove of the incoming line branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com