Phosphorus scaling case component on mechanical husking machine

A technology of shelling machine and phosphorous box, which is used in metal extrusion cleaning equipment, smoke removal, cleaning methods and utensils, etc., can solve problems such as affecting the normal operation of machinery, working environment pollution, falling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings.

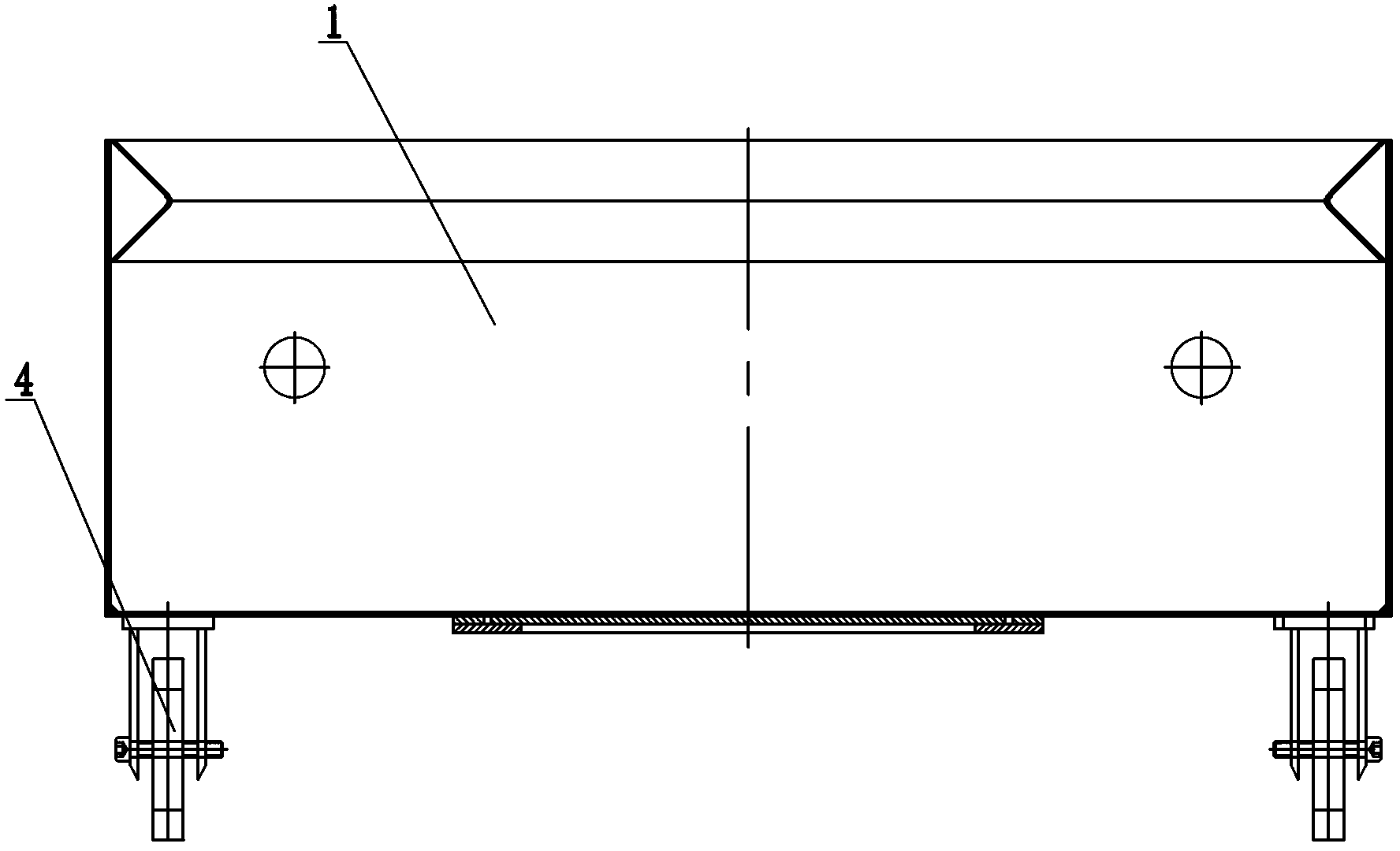

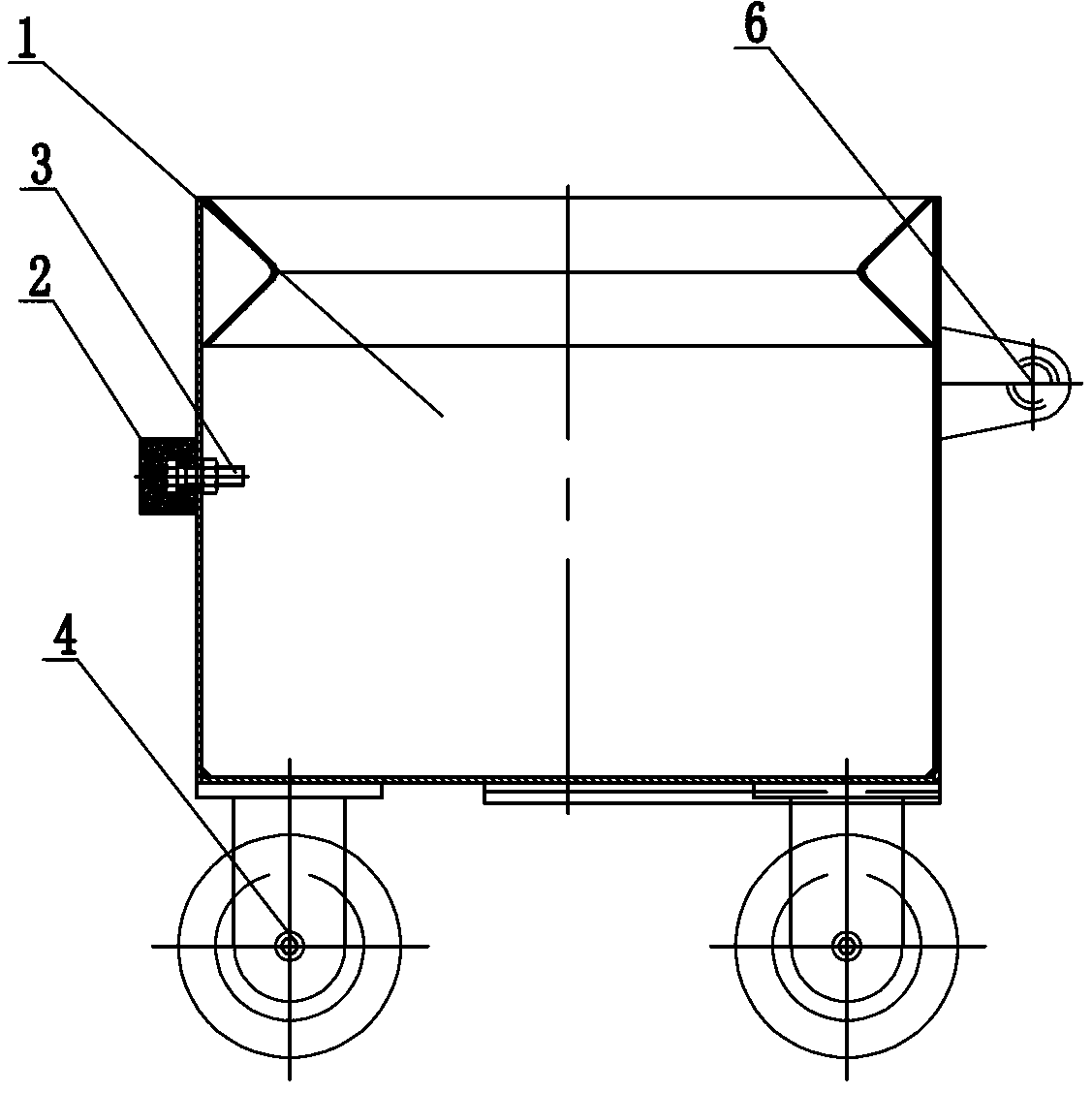

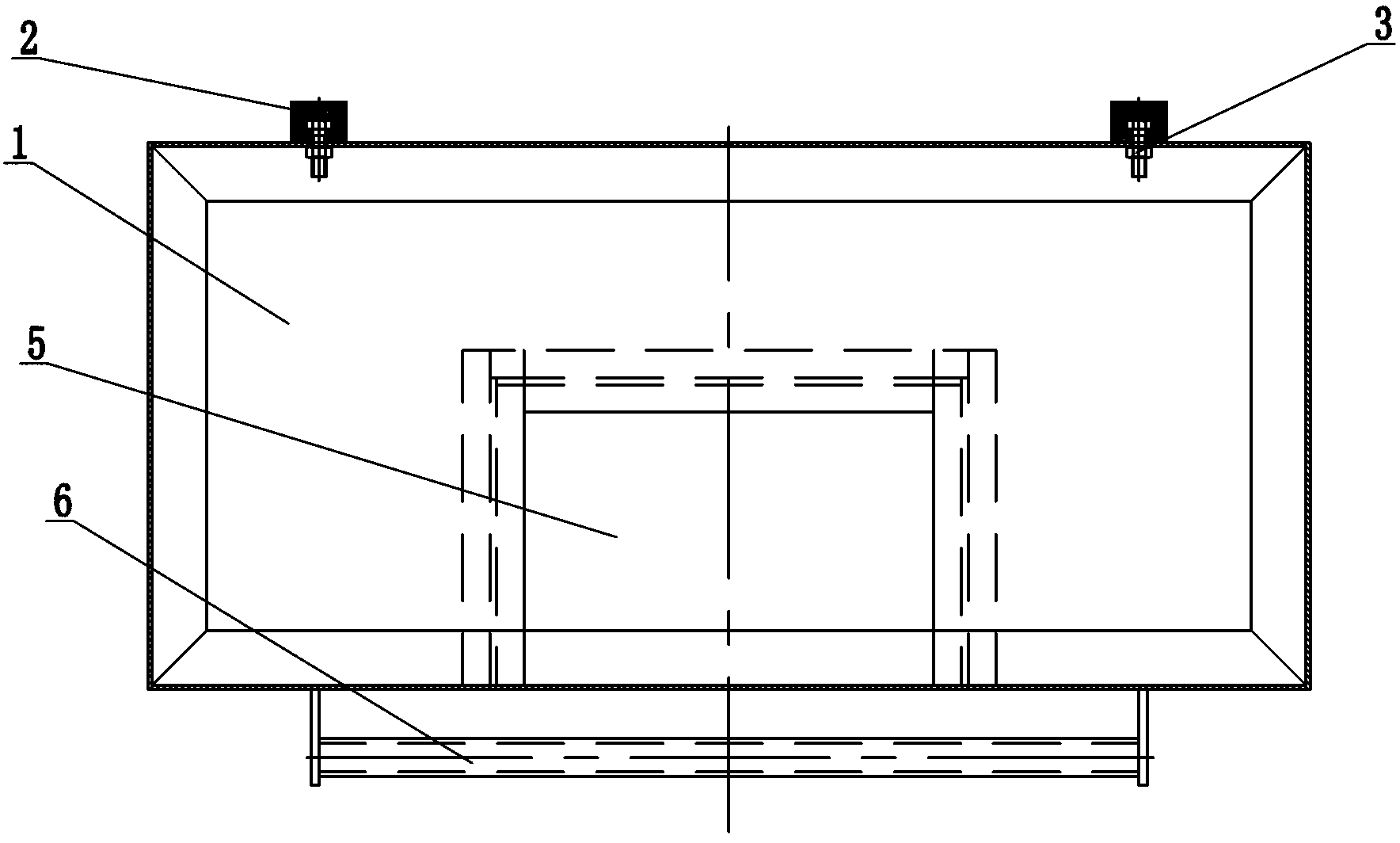

[0012] Such as Figure 1 ~ Figure 3 Shown: the phosphorus box assembly on the mechanical sheller includes a phosphorus box body 1, a buffer block 2, a nut 3, a movable wheel 4, a pumping plate 5, a handle 6, and the like.

[0013] The present invention comprises a phosphorus-binding box 1 with an open upper end, movable wheels 4 are arranged at the bottom of the phosphorus-binding box 1 to facilitate the movement of the phosphorus-binding box 1; a pumping plate is provided on the phosphorus-binding box 1 5. The pumping plate 5 is used to accept the debris dropped by the peeling machine; a handle 6 is provided on the pumping plate 5 for easy operation;

[0014] A buffer block 2 is fixed by a nut 3 on the outer wall of the phosphorous box 1 to prevent the phosphorous box 1 from colliding with other objects to cause damage.

[0015] When in use, move the phosphorus box 1 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com