Hydraulic groove rolling machine for processing bent metal pipe grooves

A grooving machine and pipe bending technology, which is applied in the field of hydraulic grooving machines, can solve the problems of low production efficiency, need for open flame operations, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

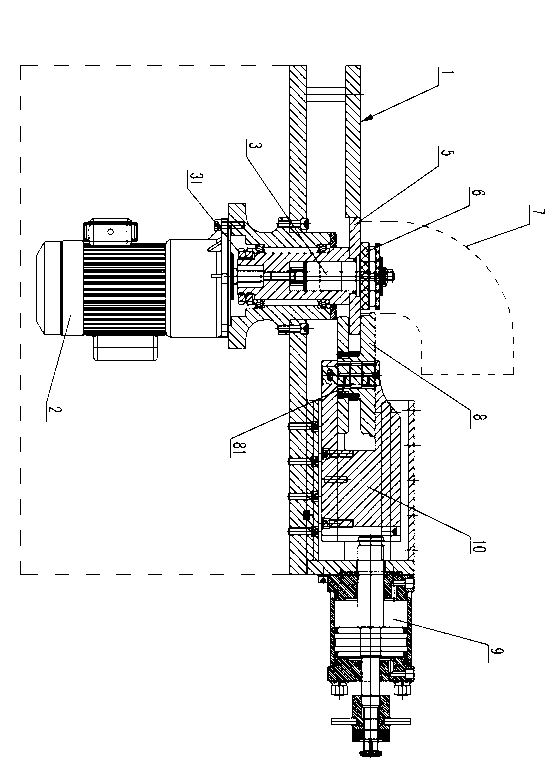

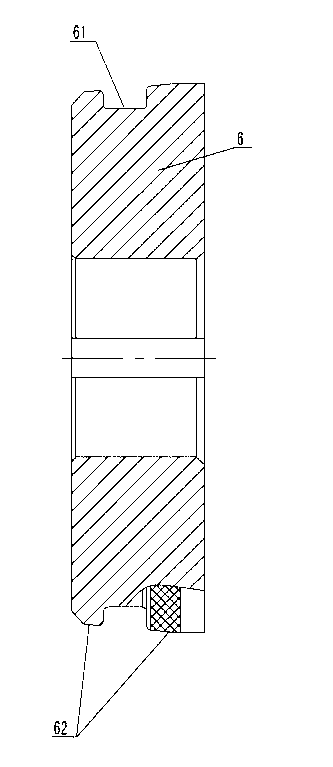

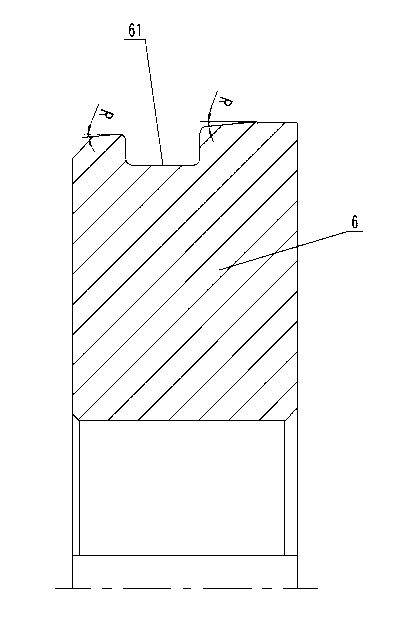

[0010] The invention relates to a hydraulic grooving machine for processing metal elbow grooves, such as figure 1 — image 3 As shown, including the frame, the motor 2 and the oil cylinder 9 are set in the frame, the motor drives the knurling wheel 6 through the main shaft, and the oil cylinder 9 drives the pressure wheel 8 through the pressure wheel frame 10, which is characterized in that the motor 2, the main shaft 3 The knurling wheel 6 is vertically arranged in the frame 1, and the knurling wheel 6 and the pressure wheel 8 are arranged horizontally. The outer wall of the knurling wheel 6 includes a pressure groove 61 and a wheel surface, and the wheel surface is tapered. The wheel surface 62, the knurling wheel 6 is provided with a supporting baffle 5, and the workpiece 7 is placed on the supporting baffle 5. This scheme is mainly used for the processing of the connecting grooves of elbow pipe fittings in stainless steel water pipes. Since the elbow pipe fittings cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com