Built-in thermal-insulating concrete block and its manufacturing method

A concrete block, thermal insulation technology, applied in the field of building construction, can solve the problems of reduced thermal insulation effect, inconvenient installation, complicated procedures, etc., and achieves good thermal insulation effect, reduced cost, and solved the effects of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

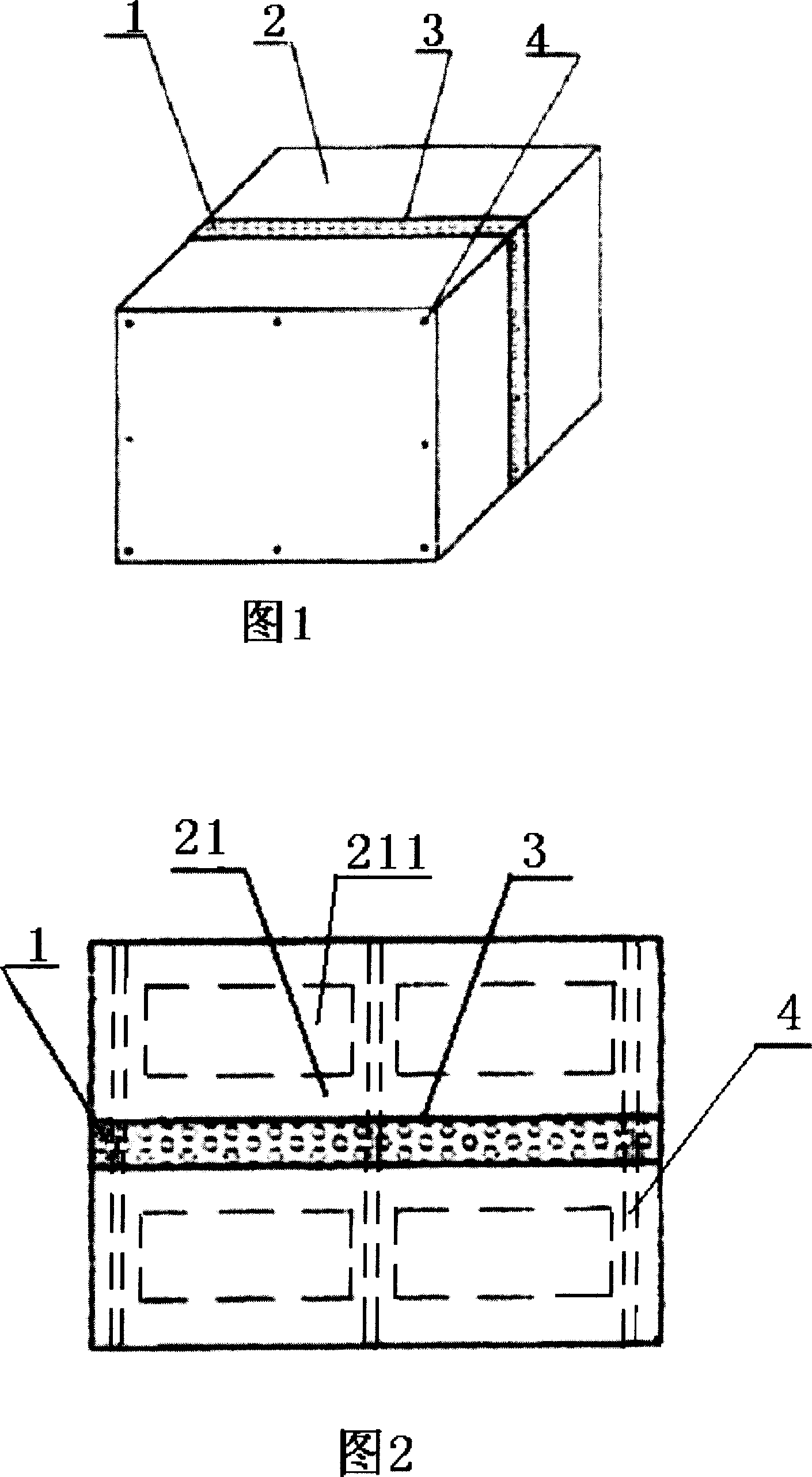

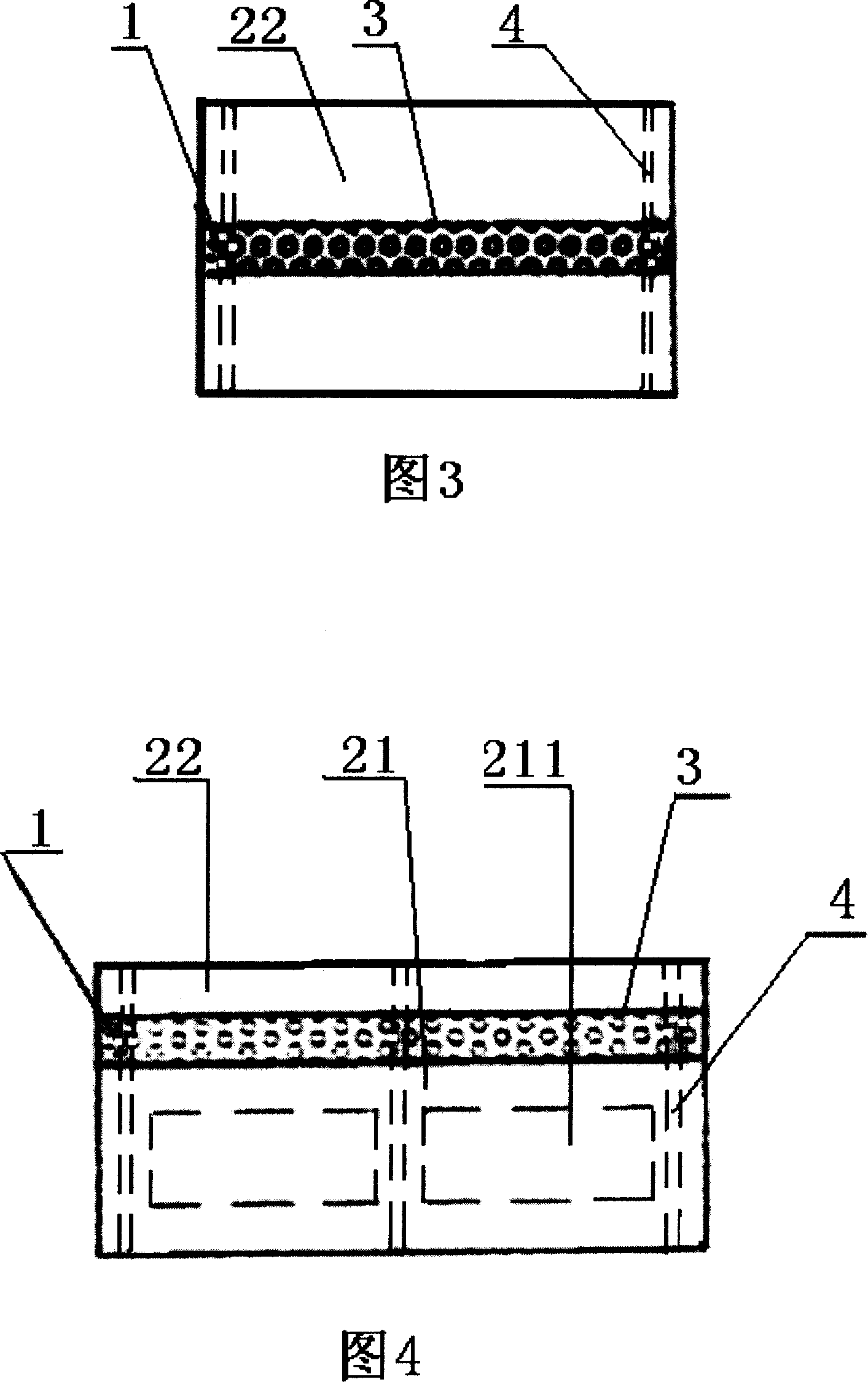

[0012] The specific embodiment of the present invention is further set forth below in conjunction with accompanying drawing, as shown in Figure 1 is the perspective view of the present invention, and it is that brick 2 is bonded together by water-based interface agent 3 on both sides of thermal insulation material 1, simultaneously in manufacturing process Several reinforcing ribs 4 are also arranged, and the arrangement of the reinforcing ribs 4 is perpendicular to the insulating material 1 and connected to the bricks 2 on both sides, so that the insulating material 1 and the bricks 2 can be tightly connected to form a whole.

[0013] Its manufacturing method is: ① brush the water-based interface agent 3 on both sides of the thermal insulation material 1 suitable for the size of the mold; A reinforcing rib 4, the reinforcing rib 4 passes through the insulation material 1 and is perpendicular to it; ④ Pour the configured brick 2 material into the mold;

[0014] Brick 2 materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com