Monorail crane lifting beam hydraulic control system and working method thereof

A technology of hydraulic control system and working method, which is applied to mechanical equipment, load hanging elements, fluid pressure actuating devices, etc., can solve problems such as inability to manually release, hidden dangers, and slow lifting speed of lifting beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

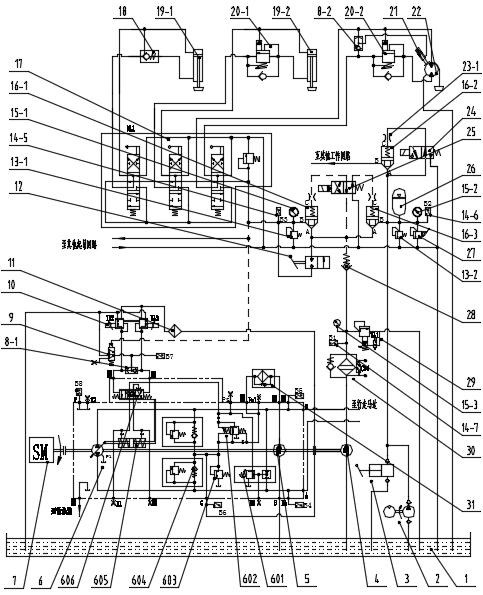

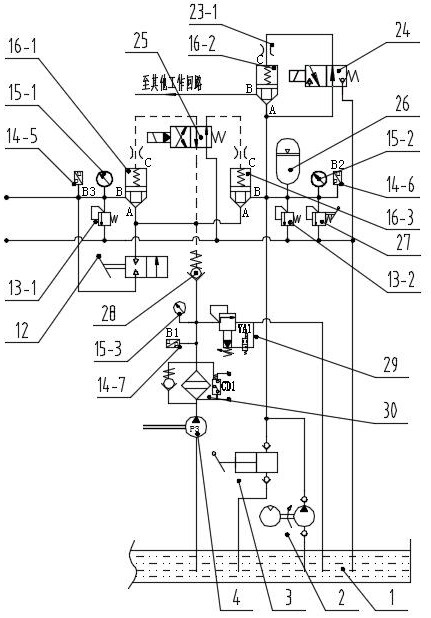

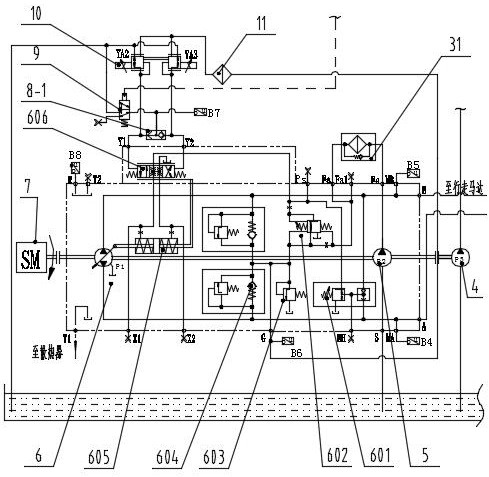

[0024] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

[0025] like Figures 1~3 As shown in the figure, a hydraulic control system for the lifting beam of a monorail crane locomotive of the present invention includes a lifting beam lifting circuit, an accumulator manual liquid charging circuit, an accumulator automatic liquid charging circuit, a lifting beam oil supply circuit, and an accumulator pressure maintaining circuit. Circuit and travel fuel supply pump assembly.

[0026] like figure 1 As shown in the figure, the lifting circuit of the hoisting beam is an executive mechanism for the lifting beam to realize the lifting operation, and it is set according to the structure of different hoisting beams. The motor lifting beam control valve group, the multi-way reversing valve 17 is the reversing valve group for the lifting beam to realize the lifting operation. It has the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com