Novel counter weight balance system and using method

A new technology of counterweight balance, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment and other directions, can solve the problems of reducing the pressure of support members, reducing the deformation of guide rail movement, safety hazards, etc., to reduce The effect of bearing pressure and motion deformation, smooth motion and smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

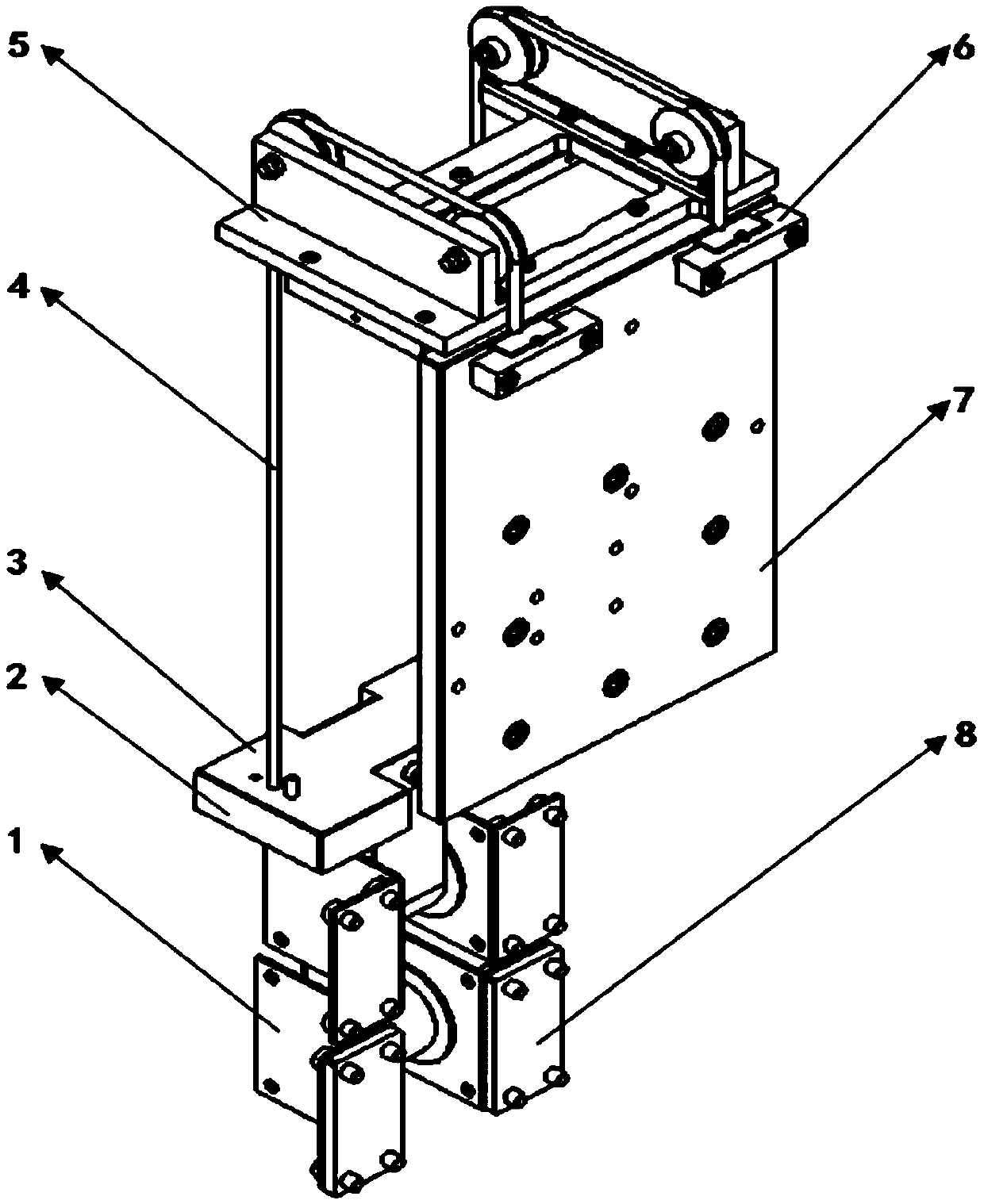

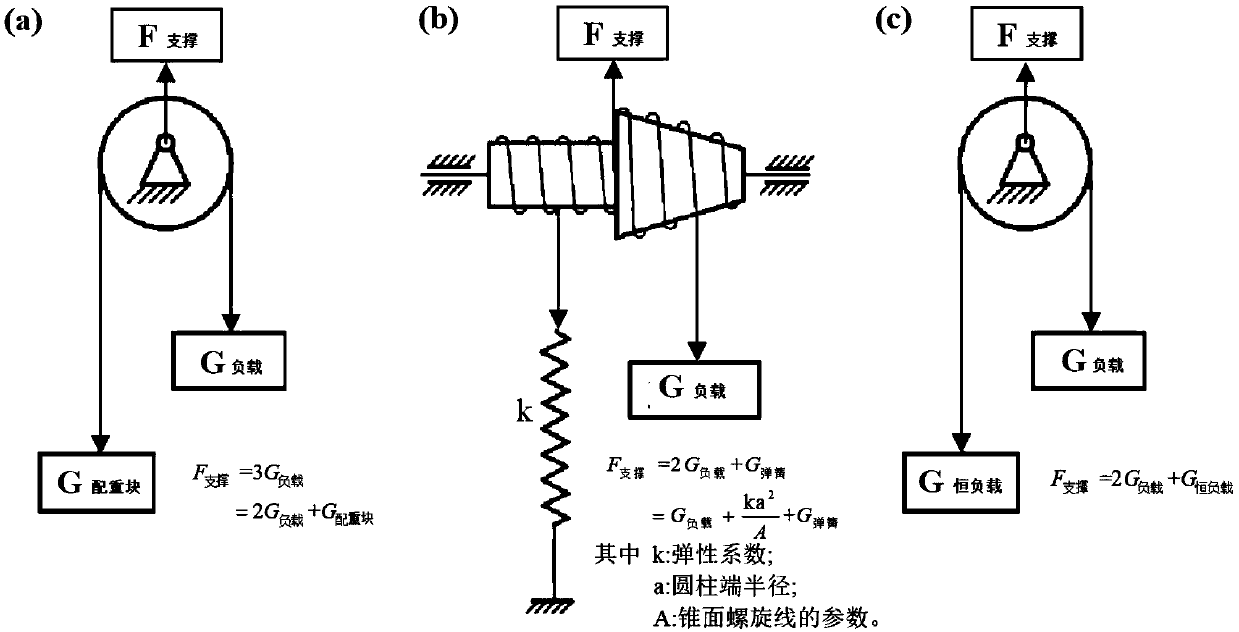

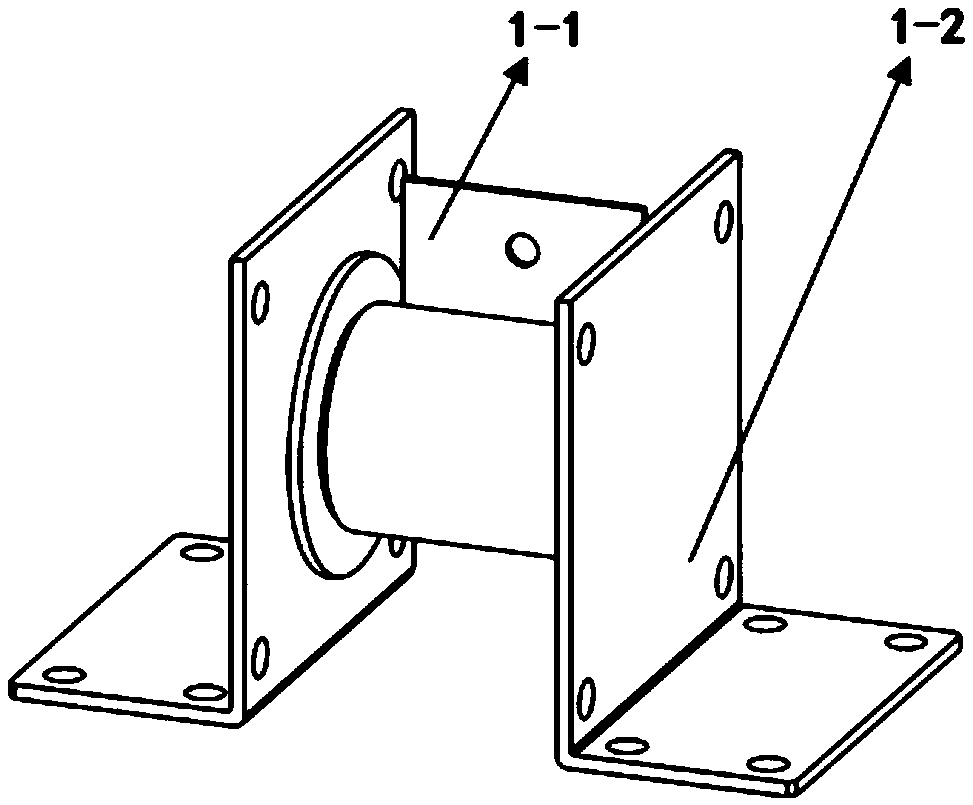

[0032] Based on the counterweight balance system of the constant load spring device 1, through the two-way locking structure 6, adopting the method of matching the side surface of the adapter plate 3 with plastic and the end face light hole and the method of axial adjustment of the guide wheel 5-1, a method based on the constant load spring device 1 is proposed. The counterweight balance system and method of use of the load spring device 1 achieves balance of the work load while avoiding the larger self-weight of the traditional counterweight, reducing the pressure bearing of the supporting member, and reducing the movement deformation of the guide rail; The counterweight system has relatively complicated problems in structural design and processing technology; it solves the safety hazard caused by the slipping rope at the end of the rope; it improves the oscillation movement phenomenon caused by the transient deviation of the center of mass, and then realizes the adapter plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com