Inner planet phase adjusting mechanism for carton flexography slotting die cutting machine

A flexographic printing and phase adjustment technology, used in printing presses, rotary presses, printing and other directions, can solve the problems of low transmission accuracy, short service life, large transmission gap, etc., and achieve high transmission accuracy, long service life, and transmission. small gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means of the present invention achieve the purpose and effect and be easy to understand, it will be further elaborated below in conjunction with the drawings.

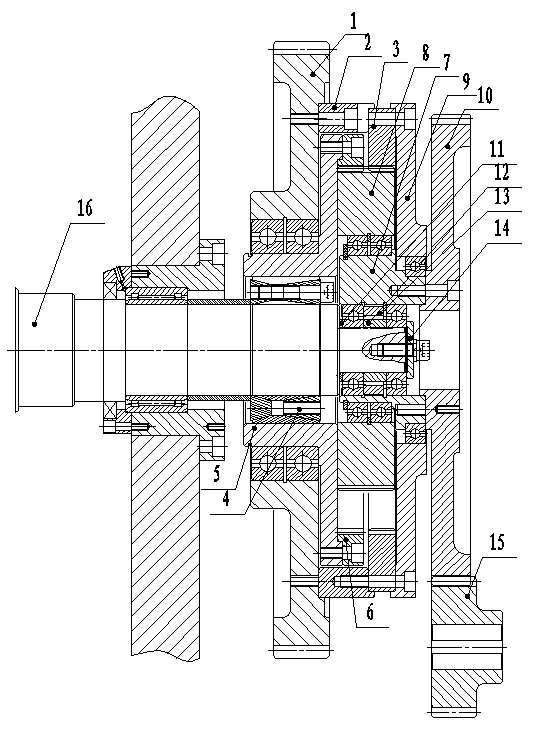

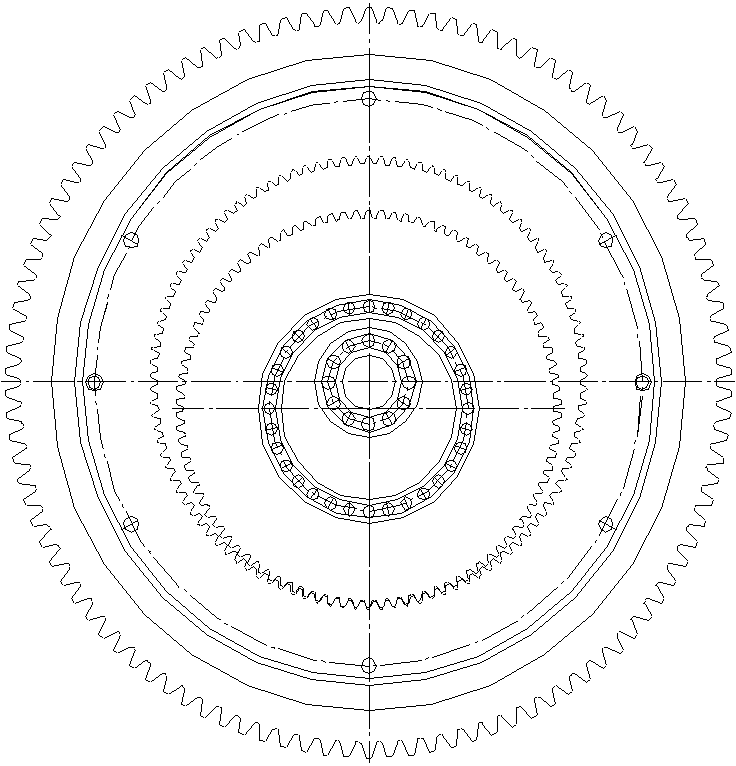

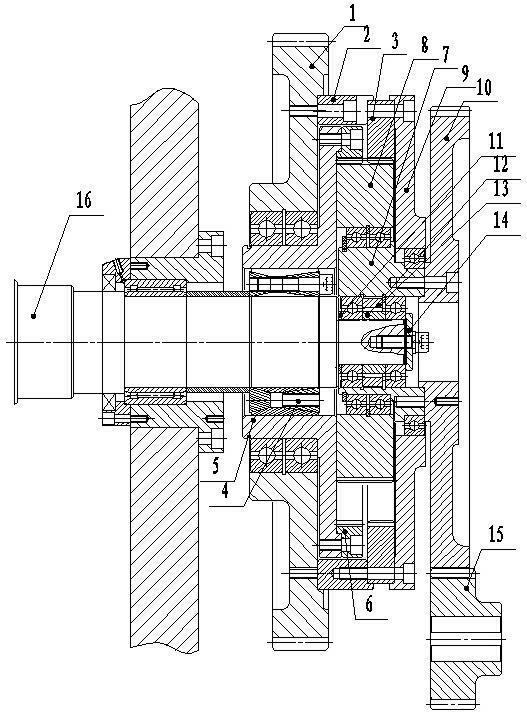

[0011] Such as figure 1 , 2 As shown, the carton flexographic printing slotting die-cutting machine includes the printing plate roll of the printing unit, the slotting upper shaft of the slotting unit and the stencil roll of the die-cutting unit, and the roller shafts of the printing unit, slotting unit and die-cutting unit The inner planetary phase adjustment mechanism is installed on the top, and the inner planetary phase adjustment mechanism includes the main transmission bull gear 1, the active internal gear fixed ring 2, the active internal gear 3, the passive internal gear fixed ring 5, the passive internal gear 6, and the planetary gear eccentric Wheel 7, planetary gear 8, fixed ring 9 of planetary eccentric wheel and large plate adjustment gear 10, the main drive large gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com