Engine water blocking cover pulling and detaching tool and pulling and detaching method thereof

A technology for removing tools and engine cylinder heads, applied in the field of engine parts manufacturing, can solve problems such as cylinder block scrap, operation failure, cost increase, etc., and achieve the effects of cost saving, resource waste reduction, and large transmission force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

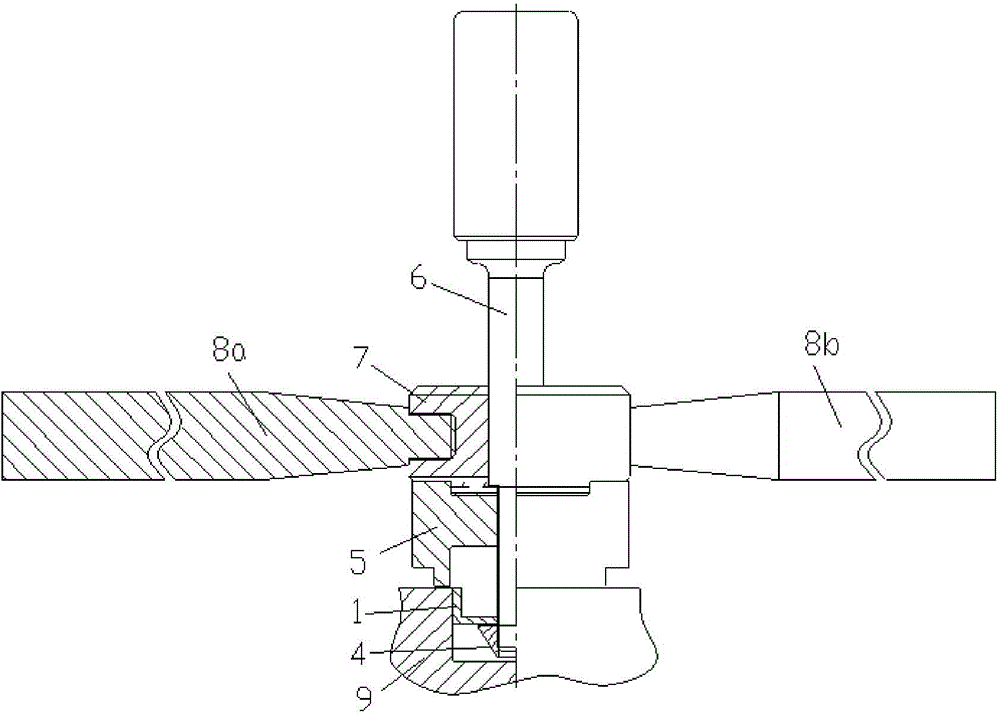

[0049] Such as figure 1 Shown is a schematic diagram of the structure of the engine water blocking cover removing tool for removing the water blocking cover of the present invention.

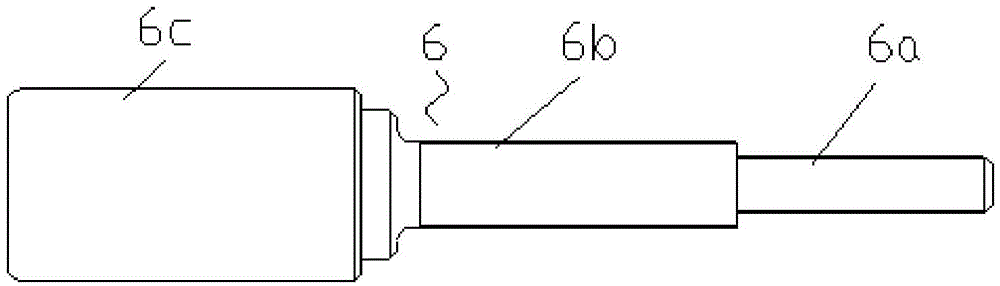

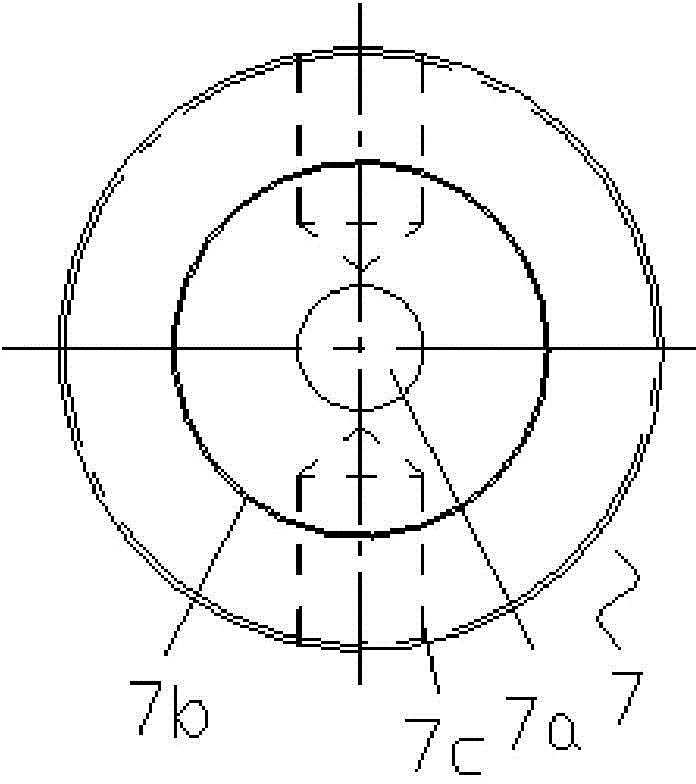

[0050] by figure 1 It can be seen that the engine water plug removal tool of the present invention includes: a plug nut 4, which is arranged under the water plug 1 to be removed, and has a first threaded hole 4a arranged in the center thereof, and the first threaded hole 4a is connected to the water The center hole of the plug cover 1 corresponds to the position of the center hole; the screw lifting device is placed above the water plug cover 1 to be removed, and cooperates with the cover nut 4 to sandwich the water plug cover 1 between the cover nut 4 and the screw lifting device; The bottom end of the cover pull rod 6 is provided with a first external thread portion 6a. The first external thread portion 6a vertically penetrates the central hole of the water plug cap 1 and is connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com