Turnover mechanism and carrying device

A technology of flipping mechanism and flipping platform, applied in the field of handling device and flipping mechanism, can solve problems such as inability to meet braking requirements, and achieve the effects of protecting other equipment or personnel, improving retention, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

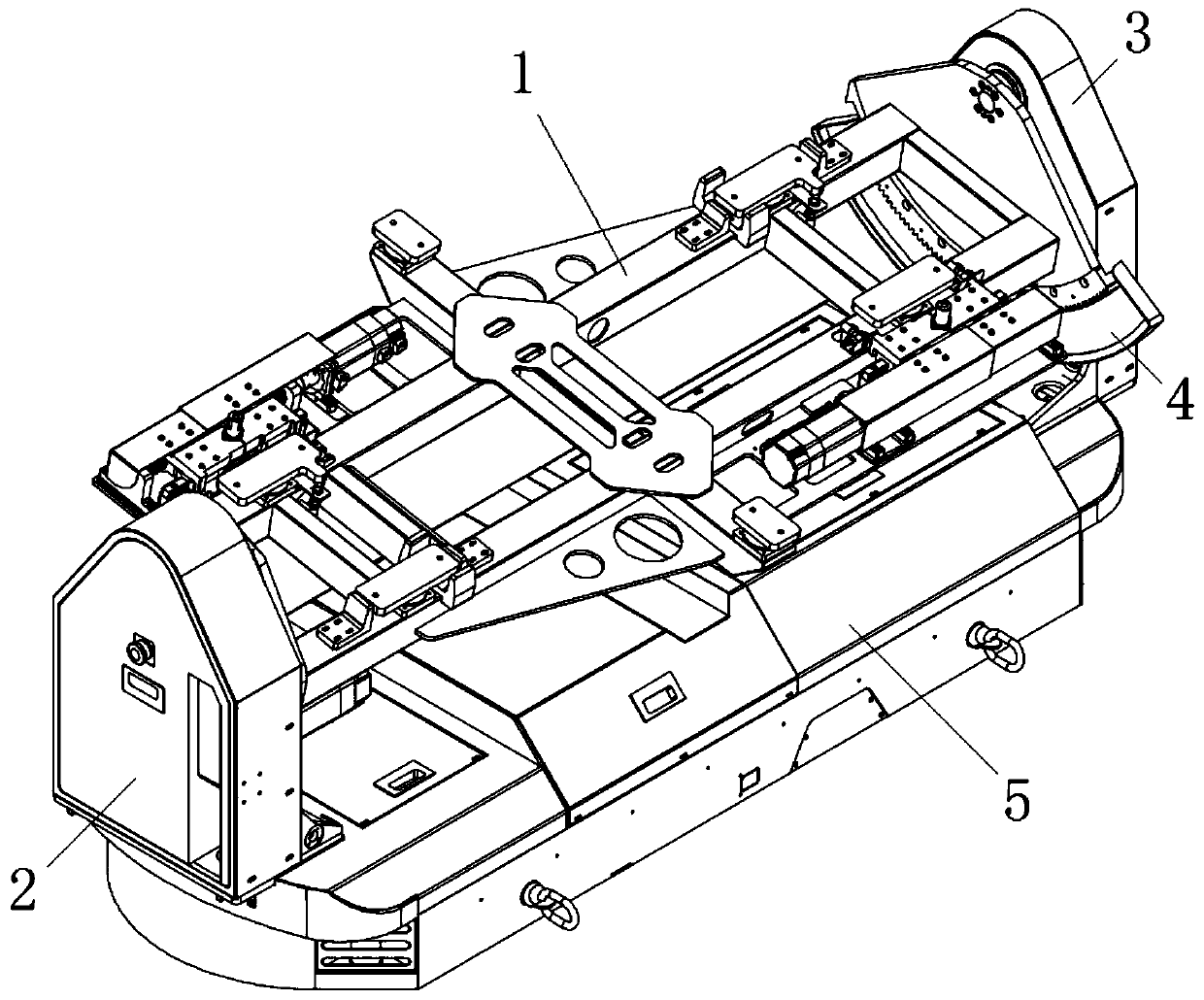

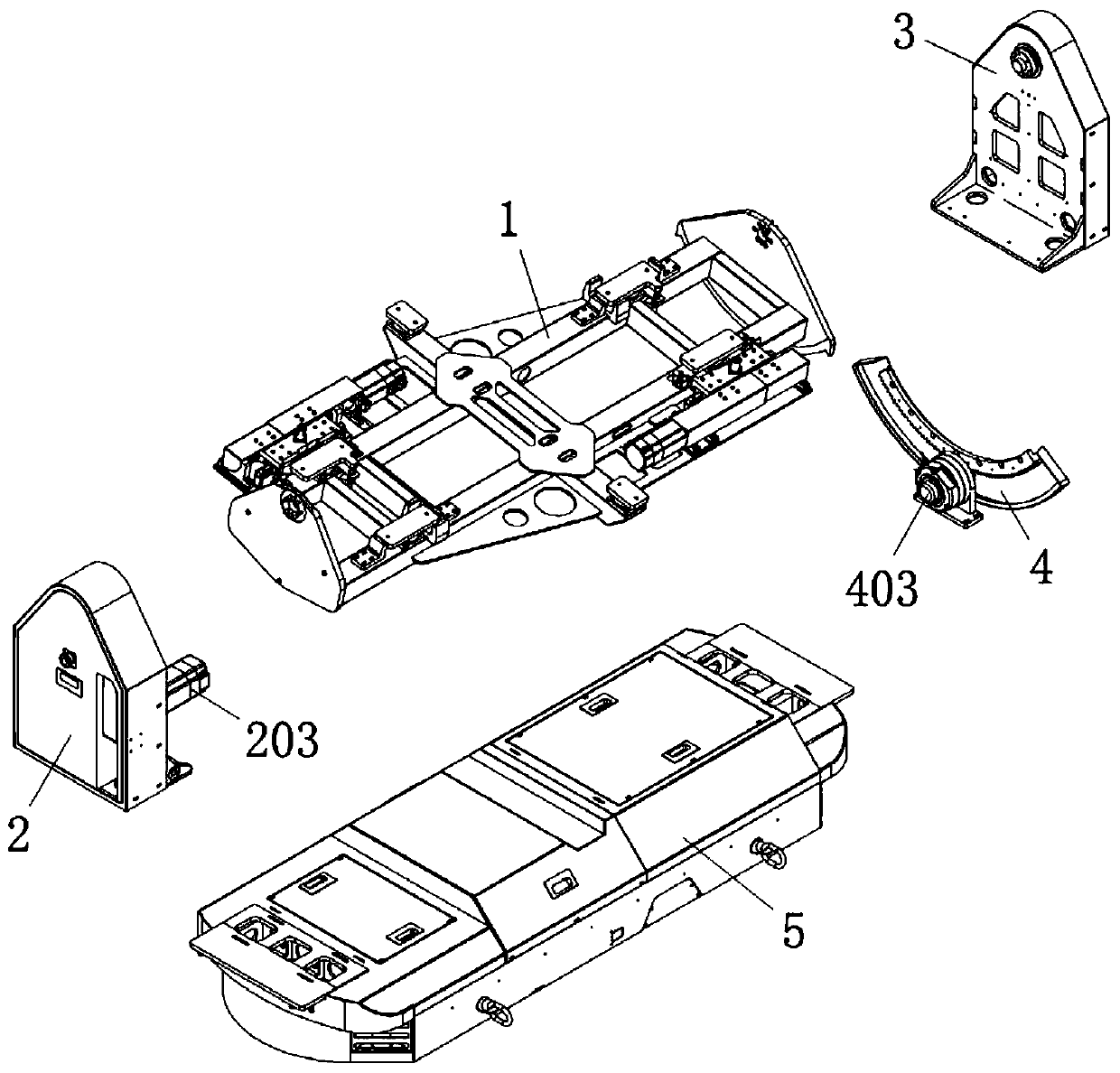

[0065] The handling device provided in this embodiment, such as figure 1 As shown, it includes: AGV trolley 5 and a buffer mechanism, wherein the turnover platform 1 of the turnover mechanism is reversibly arranged on the AGV trolley 5 through the drive assembly 2 and the support assembly 3, and when working, the turnover platform 1 can be Turn over on the AGV trolley 5 to carry out cargo.

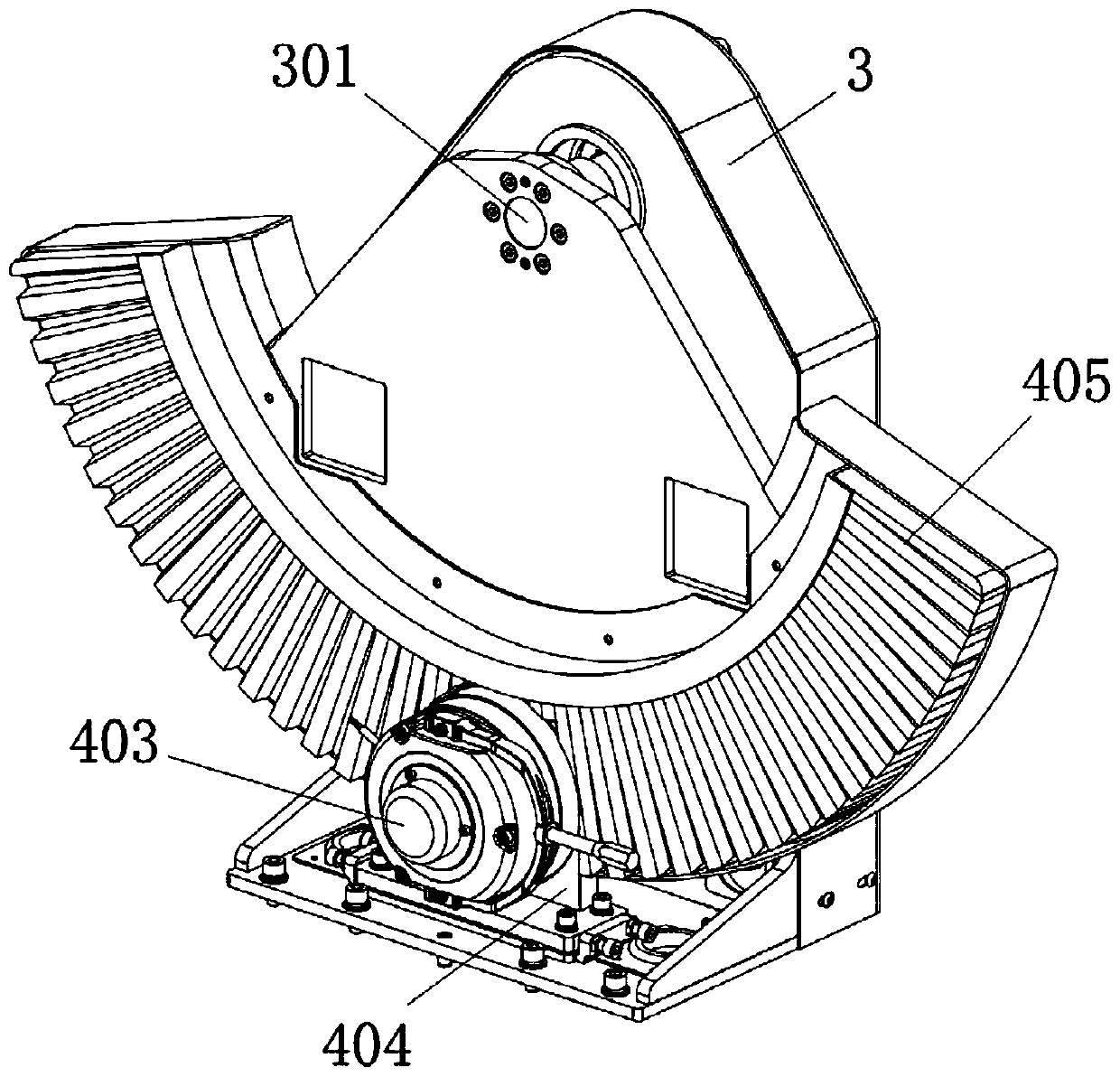

[0066] Such as figure 2 As shown, the turning mechanism includes: a turning platform 1 , a driving component 2 , a supporting component 3 and a braking component 4 . The turning platform 1 is used for carrying goods. The bottom ends of the drive assembly 2 and the support assembly 3 are fixed on the AGV trolley 5, wherein the drive assembly 2 is connected to one end of the turning platform 1 for driving the turning platform 1 toward at least the left and right sides Inverting, the support assembly 3 opposite to the drive assembly 2 is connected to the other end of the inversion platfor...

Embodiment 2

[0078] The driving assembly 2 of the buffer mechanism provided in this embodiment, such as Figure 9 As shown, it includes: a driving motor 203, a driving wheel 202, a belt 206, a driven wheel 201 and a tensioning device.

[0079] Specifically, the motor may be a stepping motor, the driving wheel 202 and the driven wheel 201 may be synchronous wheels, and correspondingly, the belt 206 may be a synchronous belt. The tensioning pulley 208 of the tensioning device can be a smooth roller, and by a method similar to that of Embodiment 1, the elastic driving belt 206 is shifted toward one side to maintain the tensioned state of the belt 206 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com