Laser marking film

A technology of laser marking and thin film, applied in the direction of copying/marking method, synthetic resin layered products, printing, etc., can solve the problems of inability to meet the requirements of use, poor laser marking effect, less laser light absorption, etc., and achieve excellent light shielding. And thermal composite formability, good shielding and protection, and the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

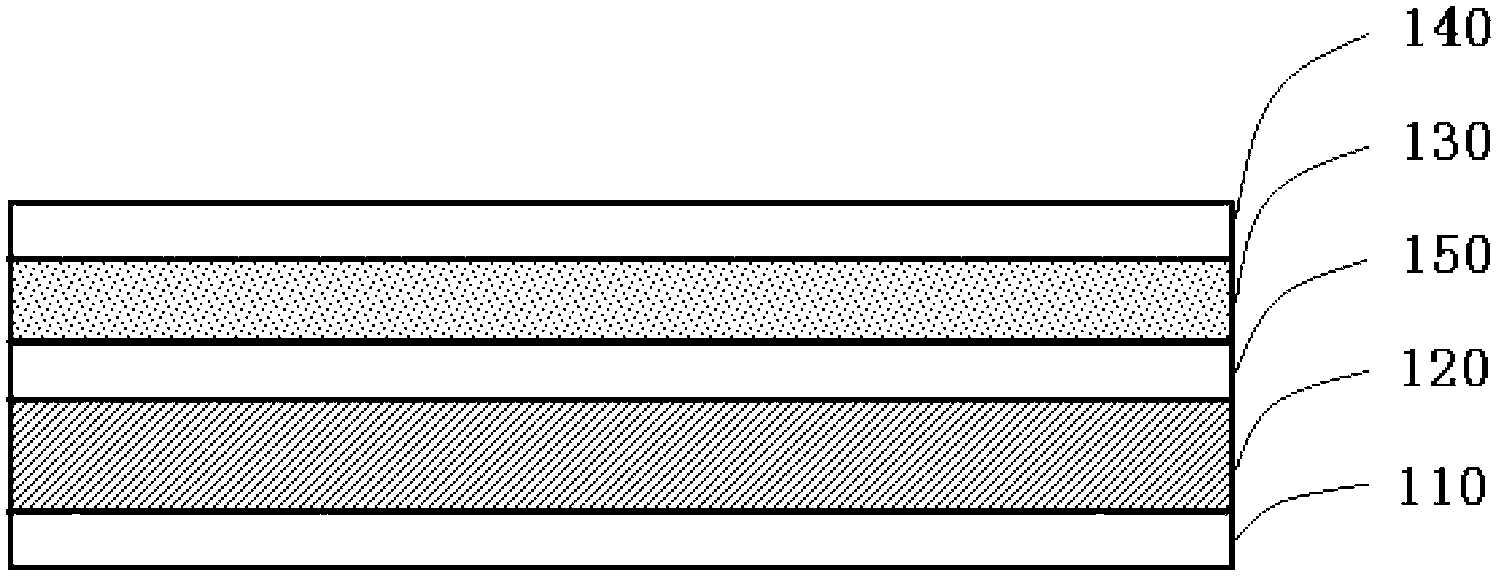

[0030] Such as figure 1 As shown, the laser marking film in this embodiment is composed of a composite film structure layer, and the composite film structure layer includes a first transparent composite layer 140, a laser marking layer 130, a second transparent composite layer 150, a cover layer 120 and a third transparent composite layer. Transparent composite layer 110 .

[0031] The laser marking layer 130 in the laser marking film 100 can provide excellent laser marking effects, and can permanently mark text and patterns with high definition and contrast under the irradiation of laser beams of different intensities, and play a significant role in security and anti-counterfeiting ; The upper surface of the laser marking layer 130 is co-extruded with a first transparent composite layer 140, and the first transparent composite layer 140 can protect the internal structure layer well, while providing excellent thermal composite molding properties, to meet the needs of thermal ...

Embodiment 2

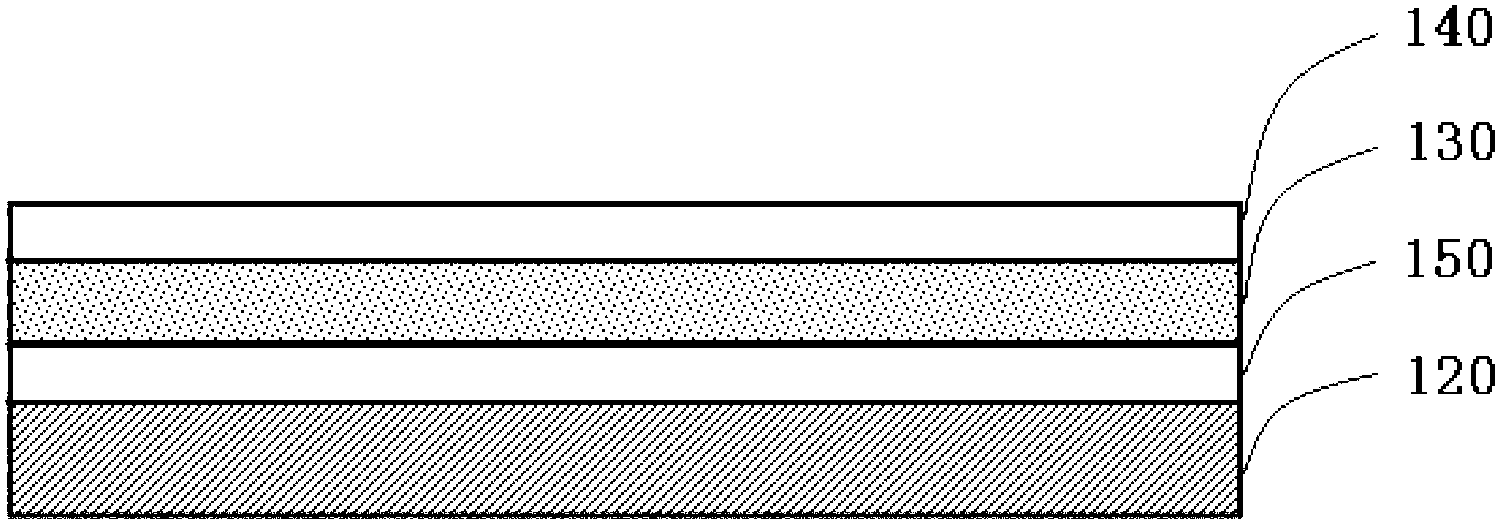

[0045] Such as figure 2 As shown, the laser marking film in this embodiment is composed of a composite film structure layer, which includes a first transparent composite layer 140 , a laser marking layer 130 , a second transparent composite layer 150 and a cover layer 120 .

[0046] The feature of this embodiment is that one layer of third transparent composite layer 110 is added on the basis of Embodiment 1, which can further simplify the processing technology and cost, but the effect of laser marking will not be affected, and it can also meet the requirements of use. Other parts of this embodiment And the functions and effects are the same as in Embodiment 1, so the description will not be repeated.

Embodiment 3

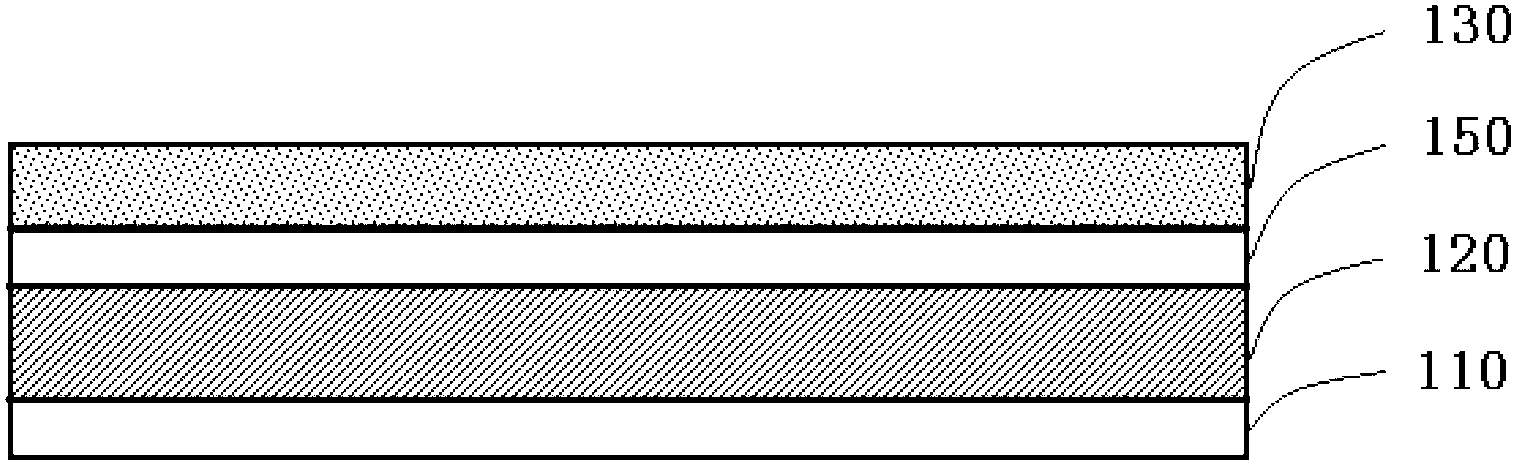

[0048] Such as image 3 As shown, the laser marking film in this embodiment is composed of a composite film structure layer, which includes a laser marking layer 130 , a second transparent composite layer 150 , a cover layer 120 and a third transparent composite layer 110 .

[0049] The feature of this embodiment is that one layer of the first transparent composite layer 140 is reduced on the basis of Embodiment 1, the lower surface of the laser marking layer 130 is the second transparent composite layer 150, and the other side of the second transparent composite layer 150 is a cover Layer 120 , the lower surface of the cover layer 120 is the third transparent composite layer 110 .

[0050] The characteristics are the same as that of Embodiment 2. The reduction of one layer of transparent composite layer can further simplify the processing technology and cost, but the effect of laser marking will not be affected, and it can also meet the requirements of use. Other parts of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com