Photooxidation-resistant composite packaging film as well as preparation method and application thereof

A composite packaging film, anti-photooxidation technology, applied in chemical instruments and methods, food ingredients as antioxidants, packaging, etc., can solve the problem of no phytosterol photooxidation packaging film, etc., achieve excellent light shielding properties, simple raw materials Easy to obtain, the effect of improving oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Membrane making

[0042] 1. Use a plastic blown film machine to make a film, and add a film-forming material to the feed port of the blown film machine: take a certain amount of ethylene-vinyl alcohol copolymer (EVOH), add 0.5%, 1%, 2%, 3% , 4%, 5% (w / w) TiO 2 , The processing temperature of the film blowing machine is: extruder 180°C, head 220°C.

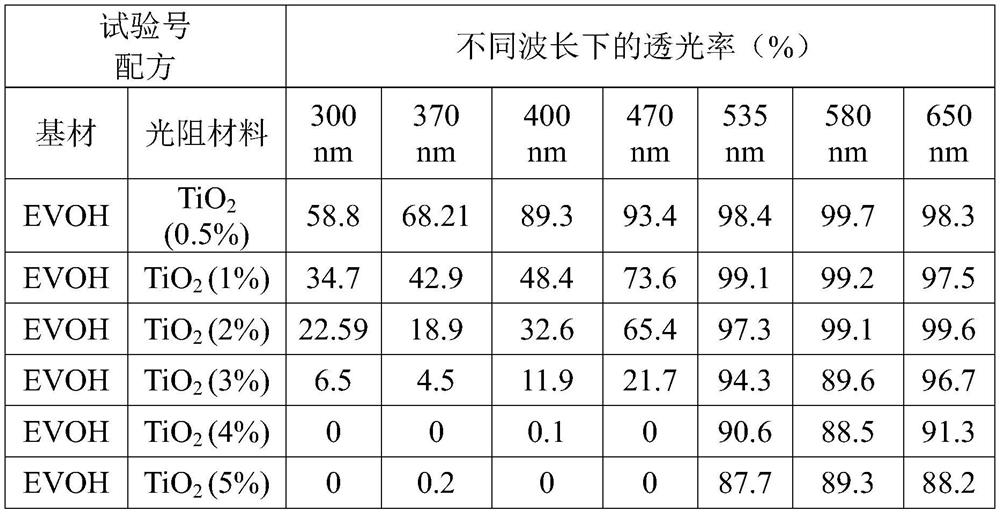

[0043] 2. Regarding the determination of the light transmittance of the packaging film, use a UV-VIS scanning spectrophotometer to test the light transmittance percentage of the film treatment, set the 2nm slit width, scan from 280 to 700nm, and the sampling interval is 1nm. Light transmittance measurements were recorded for each packaging film at 300, 370, 400, 470, 535, 580, 650 nm. The results are shown in Table 1.

[0044] Table 1

[0045]

[0046] As shown in Table 1, adding TiO 2 Can effectively shield visible light from 280 to 470nm, when TiO 2 The content is 4%, and it has the best blocking effect on spec...

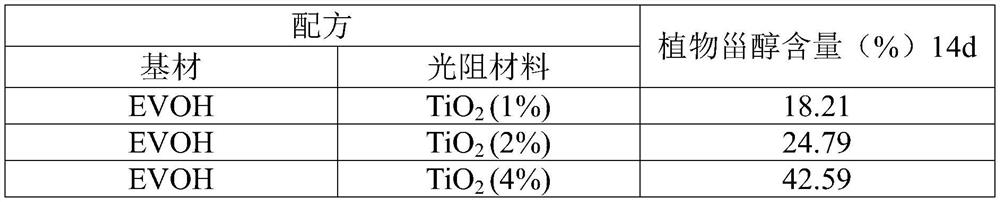

Embodiment 2

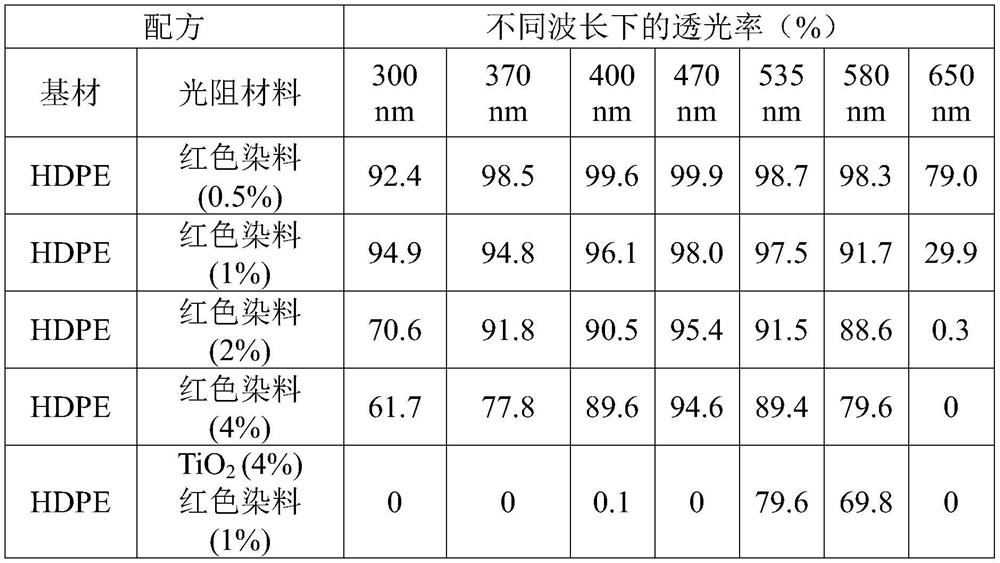

[0054] 1. Film making: use a plastic blown film machine to make a film, and add film-forming materials to the feed port of the blown film machine according to the formula in Table 3: take a certain amount of high-density polyethylene (HDPE), add red commercial pigments, TiO 2 , The processing temperature of the film blowing machine is: extruder 180°C, head 220°C.

[0055] 2. Measure the light transmittance of the packaging film, and the results are shown in Table 3.

[0056] table 3

[0057]

[0058] It can be seen from Table 3 that the red dye can effectively shield visible light above 620nm, and the red dye is 4%, which has the best blocking effect on specific visible light.

[0059] 3. Detect the impact of the packaging film on the photooxidation of phytosterols, the operation steps are the same as in Example 1. The results are shown in Table 4.

[0060] Table 4

[0061]

Embodiment 3

[0063] 1. Film making: use a plastic co-extrusion casting machine for film making: add a mixture of polyethylene 75% (w / w) and acrylic acid 25% (w / w) to the outer layer, or add a certain amount of light barrier Material TiO 2 ; Add a certain amount of pigment / dye, a mixture of deoxidizer and polyethylene to the inner layer to make a film; the inner and outer layers are extruded to form a film at the same time, and the thickness of the film provided is 110 μm. The processing temperature of the casting machine is: extruder 200 ° C, The temperature of the head is 220°C, and the temperature of the cooling roll is 25°C.

[0064] 2. Measure the light transmittance of the packaging film, and the results are shown in Table 5.

[0065] table 5

[0066]

[0067] It can be seen from Table 5 that adding TiO 2 The packaging film formed with red pigment and dye can effectively shield visible light above 280-470nm and 620nm, and effectively improve the photooxidative stability of phyto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com