Air cushion structure and air cushion carrier vehicle

A technology for transporting vehicles and air cushions, applied in the directions of air cushions, transportation and packaging, motor vehicles, etc., to achieve the effect of reducing ground requirements, improving economic benefits, and reducing expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

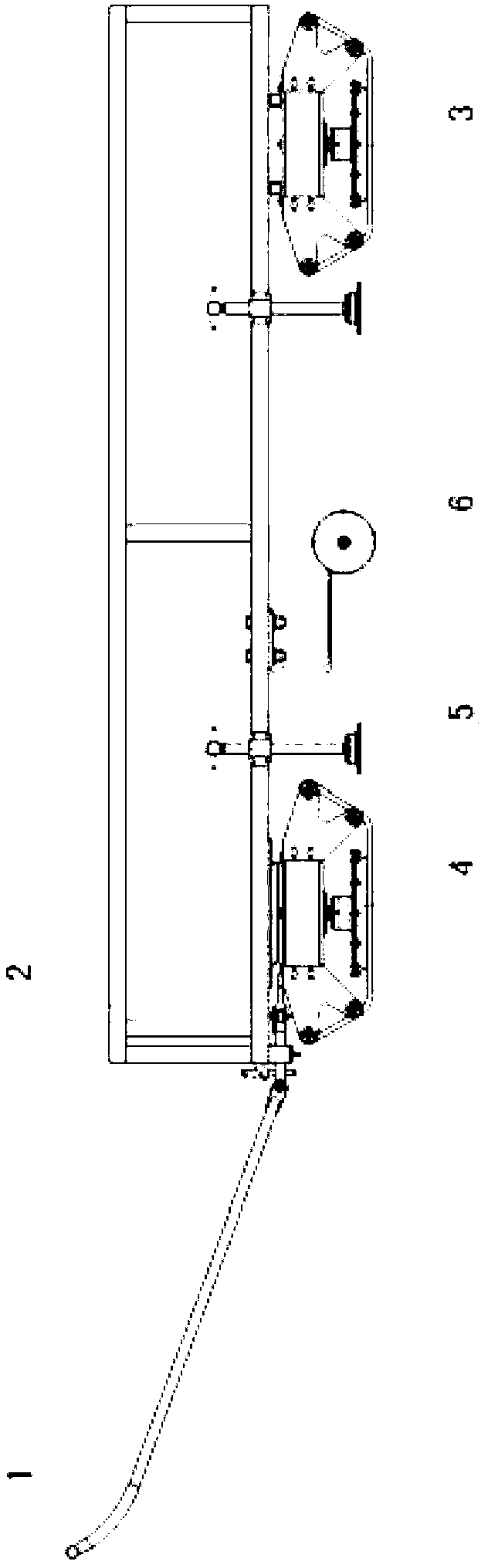

[0019] See attached figure 1 , The air cushion transport vehicle is composed of a drawbar 1, a car body 2, a fixed crawler air cushion 3, a guided crawler air cushion 4, legs 5 and guide wheels 6, etc. The fixed crawler-type air cushion 3 is directly connected with the vehicle body 2, and the guided crawler-type air cushion 4 adds end bearings on the basis of the fixed crawler-type air cushion 3, and then connects with the vehicle body. The air cushion described below uses the fixed crawler belt Formula air cushion 3 is based on launching. The steering control fork is arranged on the crawler-type air cushion 4 of guiding, is connected with drawbar 1 by connecting rod. Guide wheel 6 is installed on a cantilever beam under the car body, is pressed on the ground by certain elastic force, prevents the transport vehicle from laterally slipping in moving.

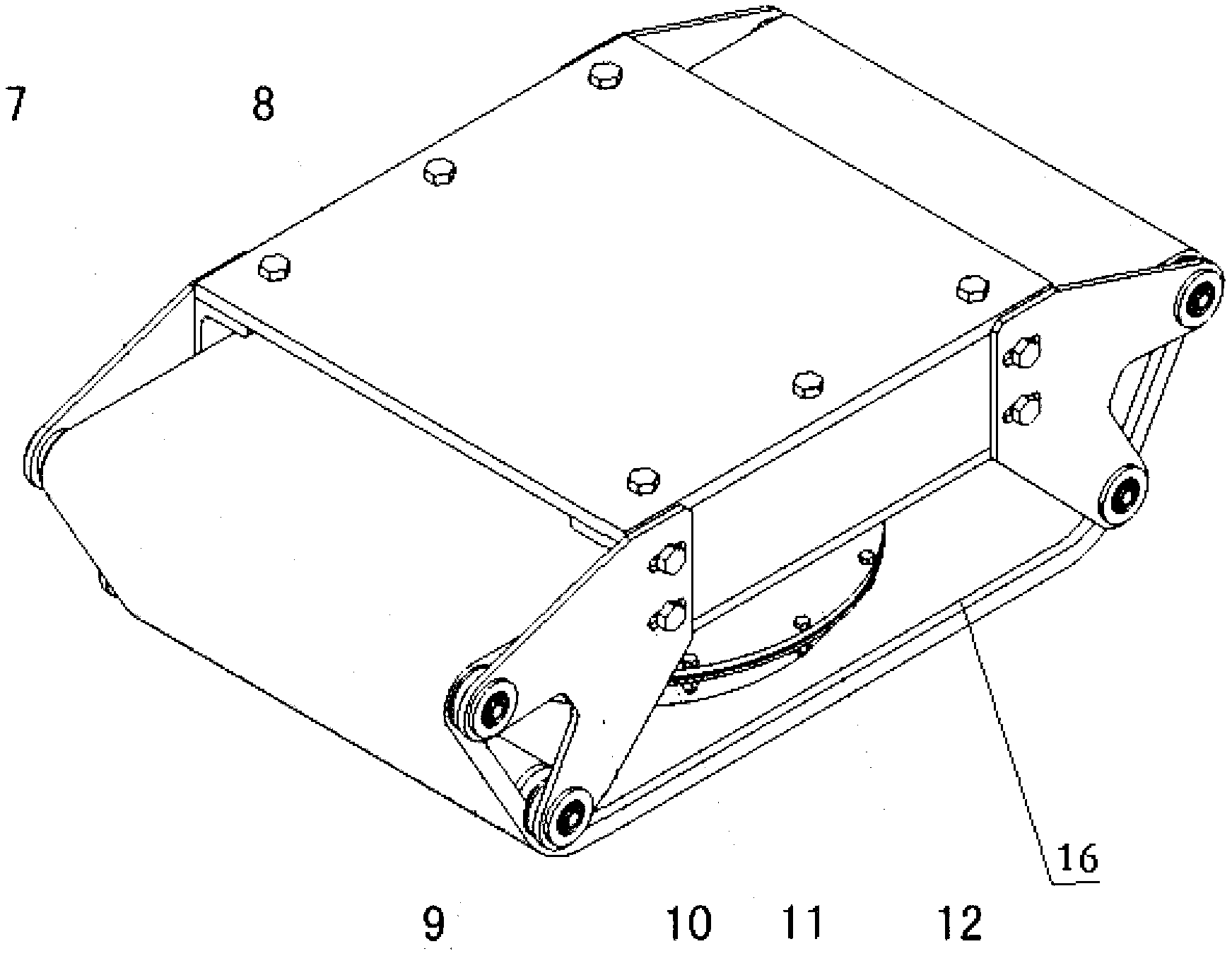

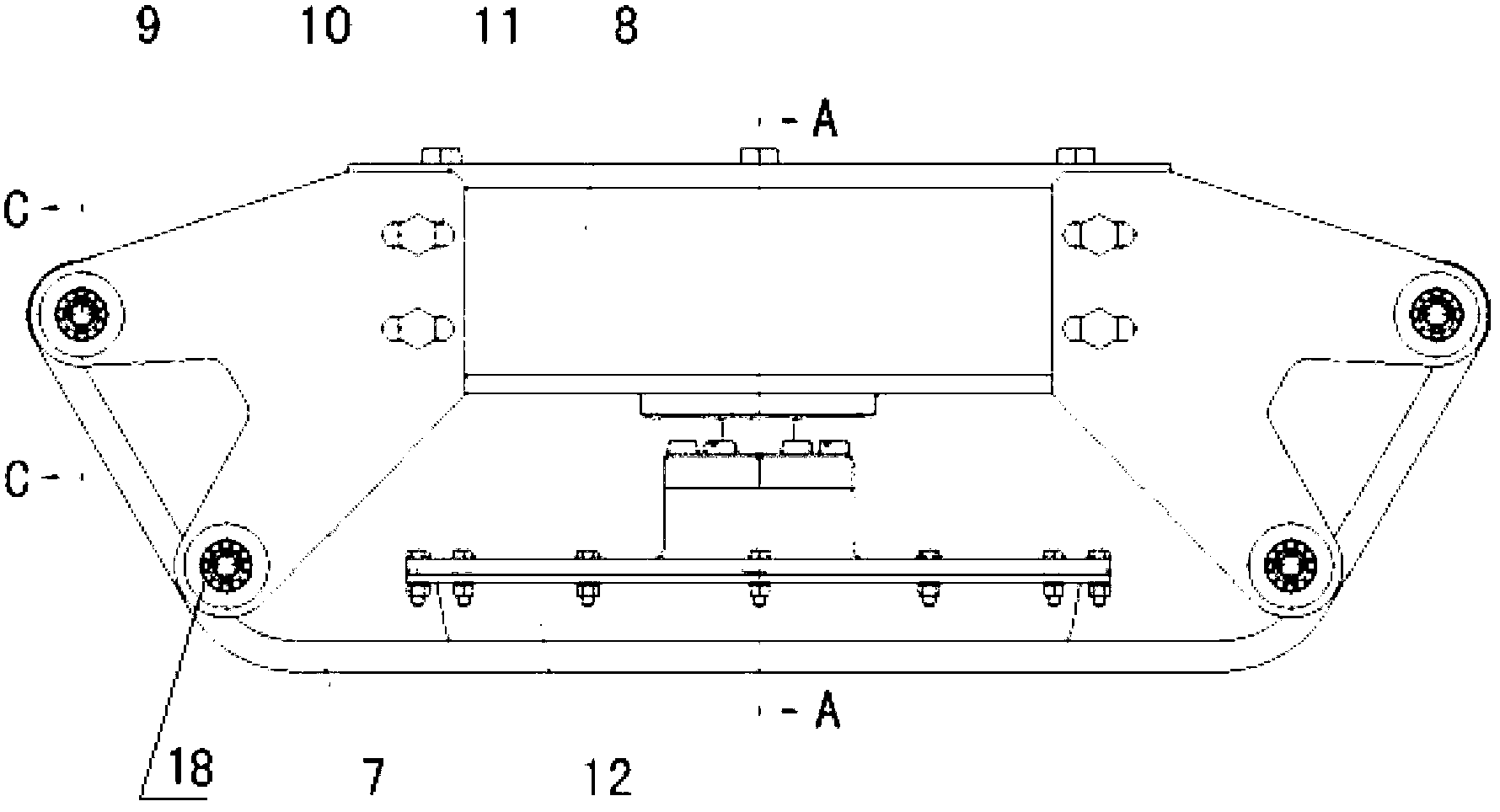

[0020] See attached Figure 2-Figure 5 , The novel crawler-type air cushion of the present application is the design after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com