Automatic packing machine for tubular product

An automatic packaging machine and pipe technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of incompatibility with mass production and low work efficiency, and achieve the effect of saving labor, improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

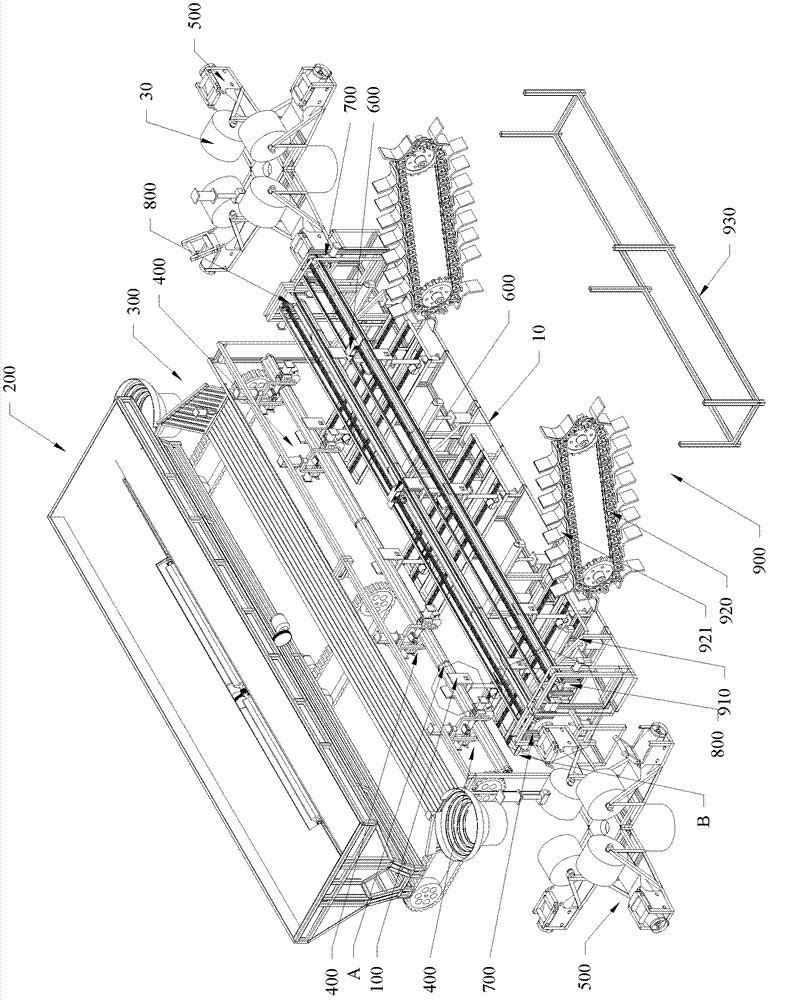

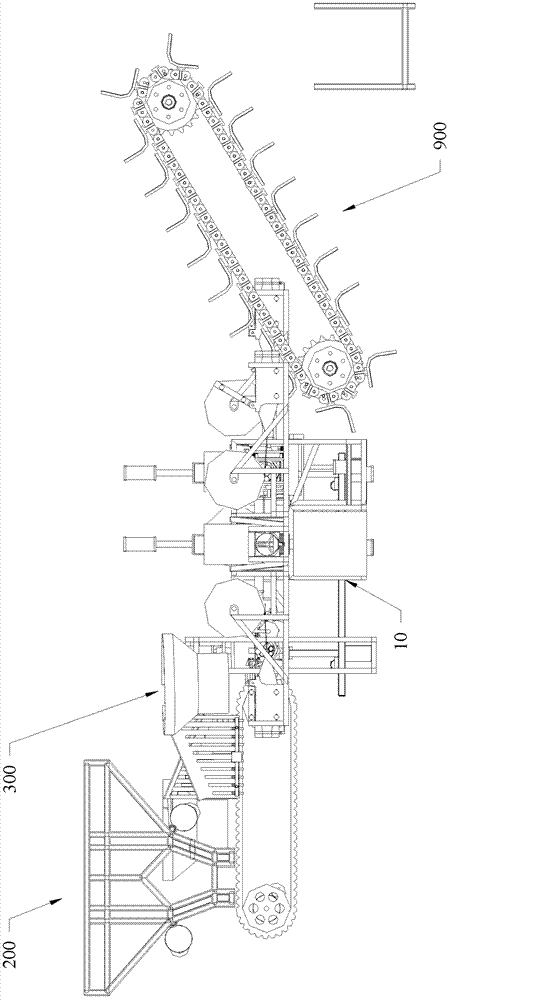

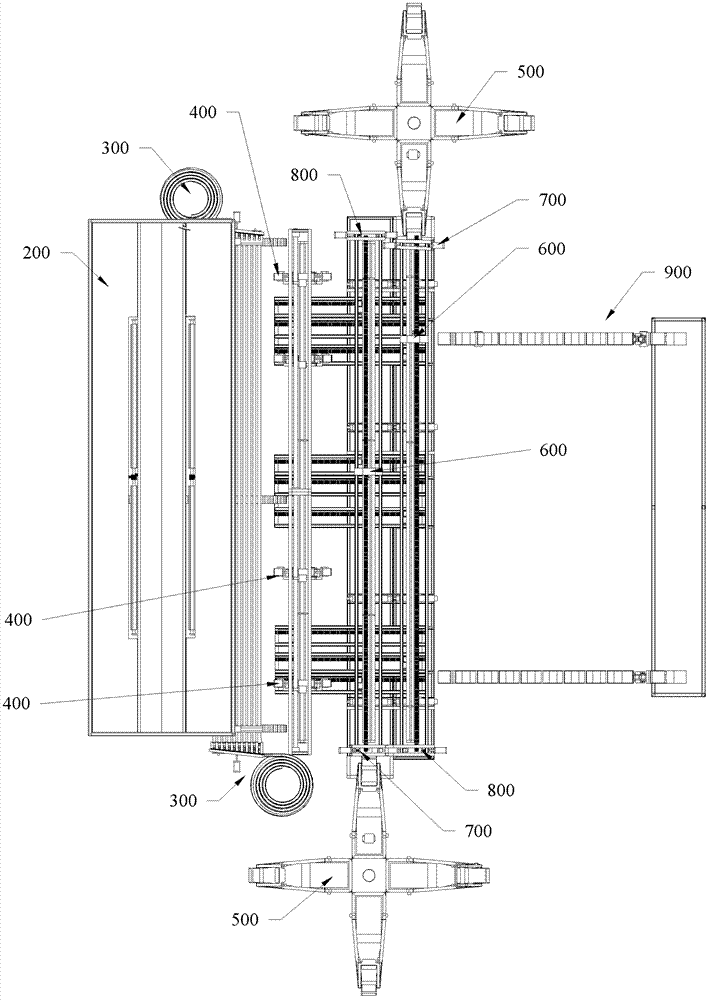

[0050] In the pipe material automatic packing machine of the present invention, mainly comprise frame 10, be arranged on frame 10 and place pipe group 20 and moveable workbench 100, be arranged on the packing bag 30 of workbench one end, pack bag 30 from One end of the pipe group is drawn to the bagging device 600 at the other end of the pipe group, the bag cutting device 700 is set between the end of the workbench 100 and the packaging bag 30 to cut off the packaging bag 30 that has been placed outside the pipe group 20, and the bag cutting device 700 is set at the working The end of the table 100 is a sealing device 800 that seals the packaging bag ends 30a at both ends of the pipe group 20, an unloading device 900 that unloads the packed pipe group 20 from the workbench 100, and controls the workbench 100, sleeve The bag device 600, the bag cutting device 700, the sealing device 800, and the unloading device 900 are control devices that work together.

[0051] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com