Boxing equipment for large-diameter industrial explosive cartridges

An industrial explosive and large-diameter technology, which is applied in the direction of packaging, transportation and packaging, and individual objects, can solve the problems of high labor intensity, casualties, and low production efficiency, so as to reduce labor intensity, reduce operators, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structural drawings further describe the present invention.

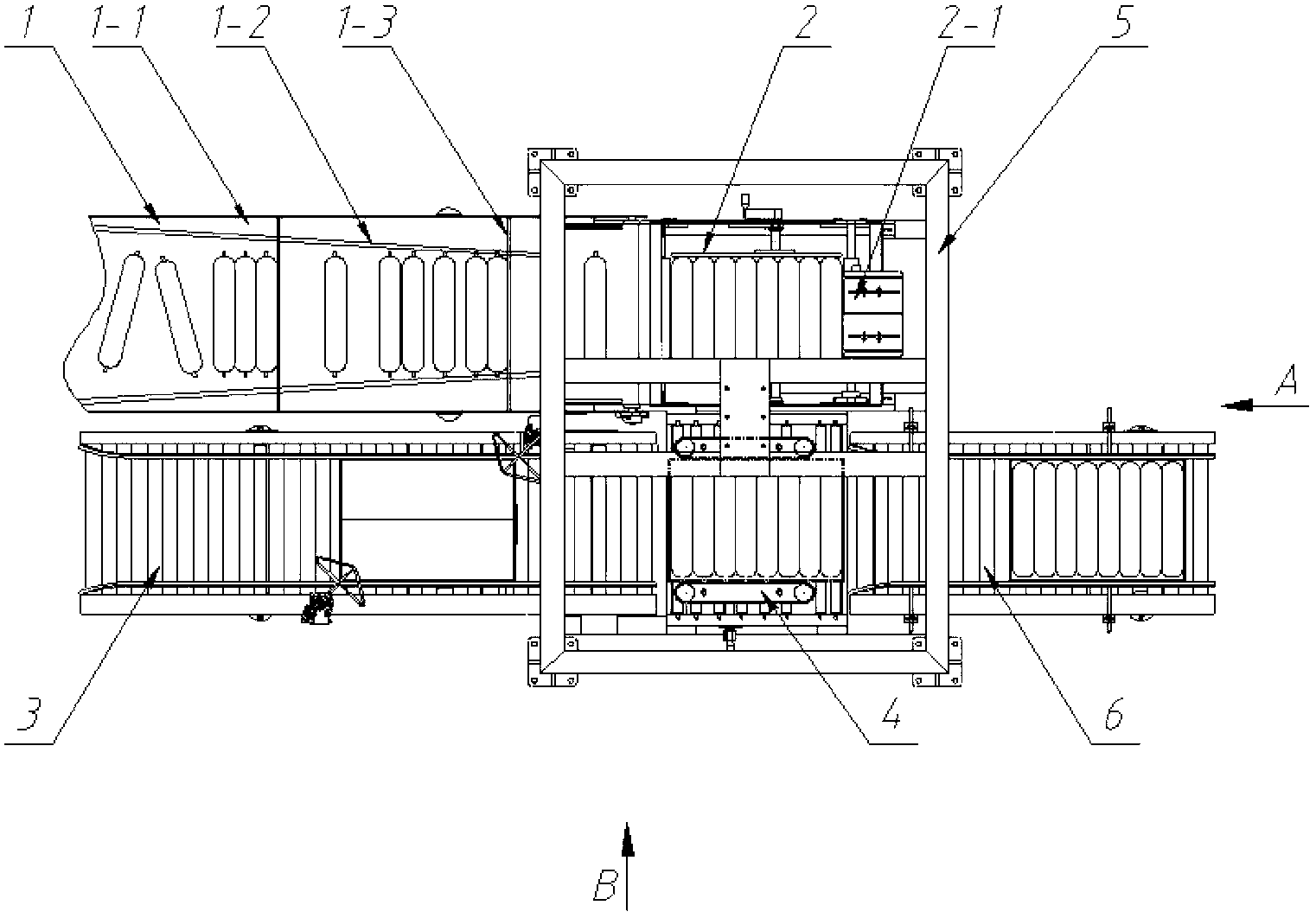

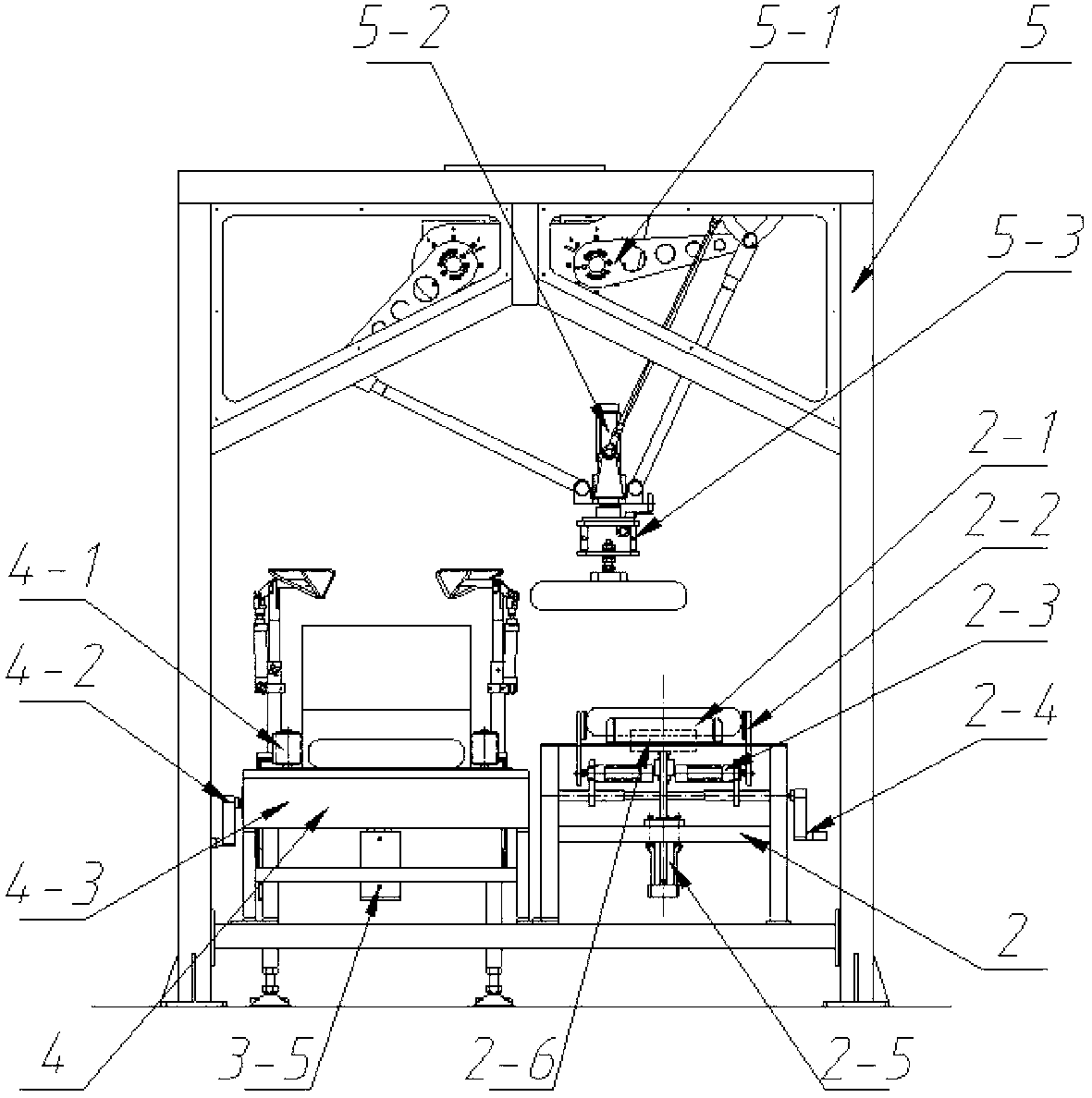

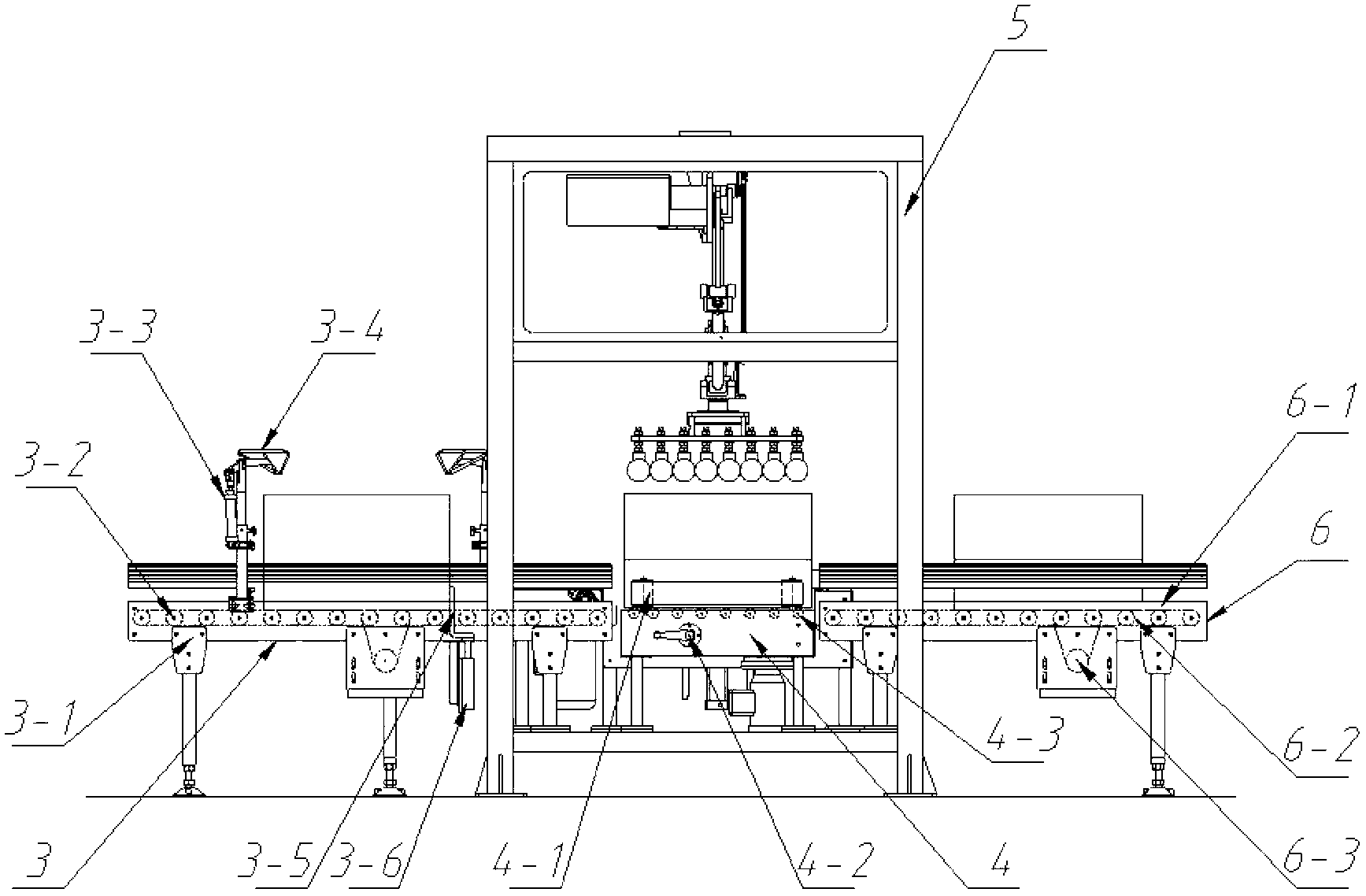

[0018] Such as figure 1 As shown, the industrial explosive large-diameter cartridge packing equipment provided by the present invention includes a cartridge arrangement belt mechanism 1, a reshaping arrangement mechanism 2, a roller conveyor box feeding mechanism 3, a carton positioning mechanism 4, a plane joint manipulator 5, and a roller conveyor output Mechanism 6, planar joint manipulator 5 adopts the planar joint manipulator disclosed in the patent ZL201020163920.2, the input end of the medicine roll arranging belt mechanism 1 is connected with the front-end conveying mechanism, and the output end of the medicine roll arranging belt mechanism 1 is connected with the shaping arrangement mechanism 2. , A plane joint manipulator 5 is installed above the reshaping and arranging mechanism 2 and the carton positioning mechanism 4, the output end of the roller conveying mechanism 3 is connected with one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com