Box-type heating furnace provided with radiation chamber with overhead radiation coils

A radiant coil and radiant chamber technology, applied in the field of heating furnaces, can solve the problems of not maximizing the heat transfer area, not making full use of the furnace space, limiting the production capacity of the device, etc., reducing equipment investment, simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

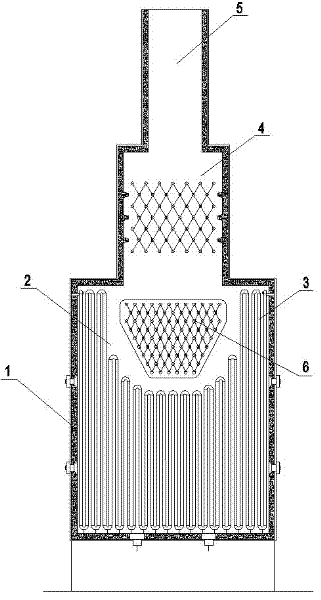

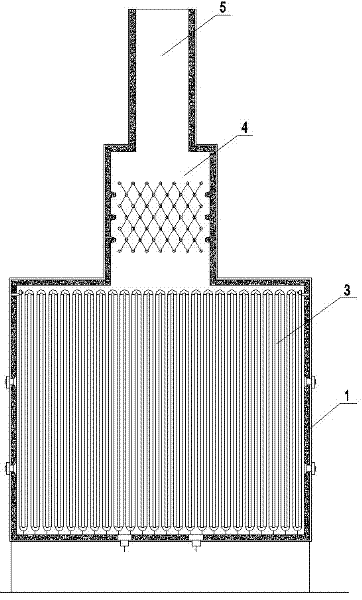

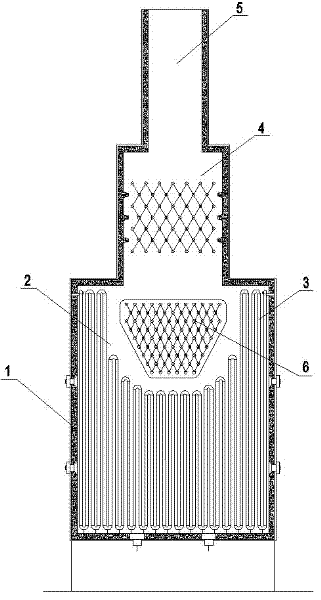

[0012] The radiation chamber top-mounted radiation coil square box heating furnace of the present invention is composed of a square box furnace body 1, a radiation chamber 2, a furnace tube 3, a convection chamber 4 and a chimney 5, and the upper end of the radiation chamber 2 is connected with the convection chamber 4 1. The upper end of the convection chamber 4 is connected to the chimney 5, and the furnace body 1 is provided with a fire door. The top of the furnace tubes 3 of the radiant chamber 2 is arranged from both sides to the middle to form a valley shape, and a radiant heat tube bundle 6 is arranged horizontally in the valley.

Embodiment 2

[0014] The radiation chamber top-mounted radiation coil square box heating furnace of the present invention is composed of a square box furnace body 1, a radiation chamber 2, a furnace tube 3, a convection chamber 4 and a chimney 5, and the upper end of the radiation chamber 2 is connected with the convection chamber 4 1. The upper end of the convection chamber 4 is connected to the chimney 5, and the furnace body 1 is provided with a fire door. The top of the furnace tubes 3 of the radiant chamber 2 is arranged from both sides to the middle to form a valley shape, and a radiant heat tube bundle 6 is placed horizontally in the valley, and the radiant heat tube bundle 6 is arranged in a horizontal coil in the radiation, and its cross-section The outer circumference is inverted trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com