Bobbin with lifting handle

A spool and handle technology, applied in the field of spools, can solve the problems of affecting work efficiency, not easy to place, and troubled by pipe penetration, and achieve the effects of convenient operation, simple structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

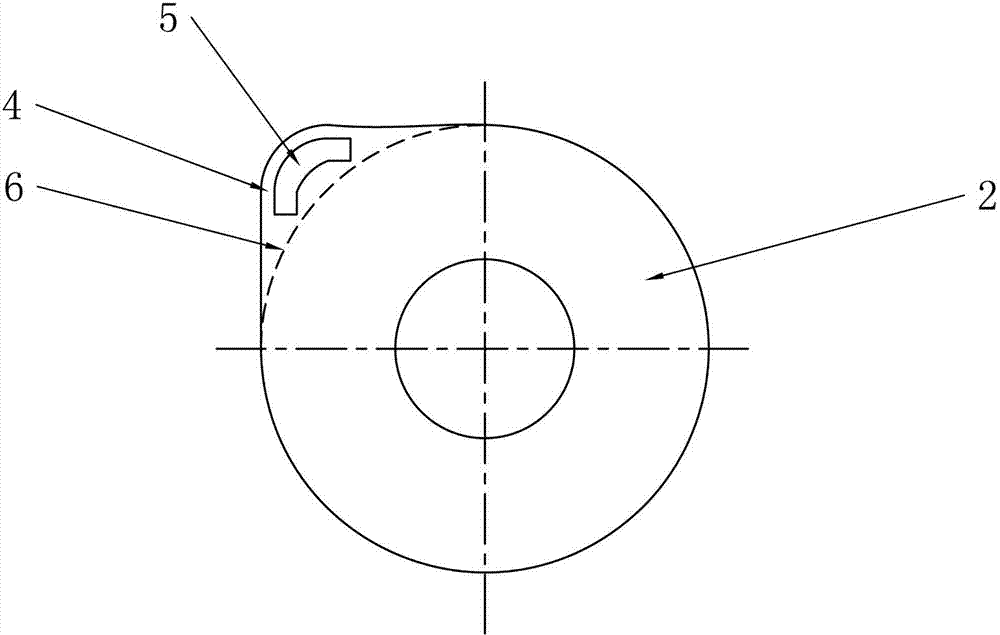

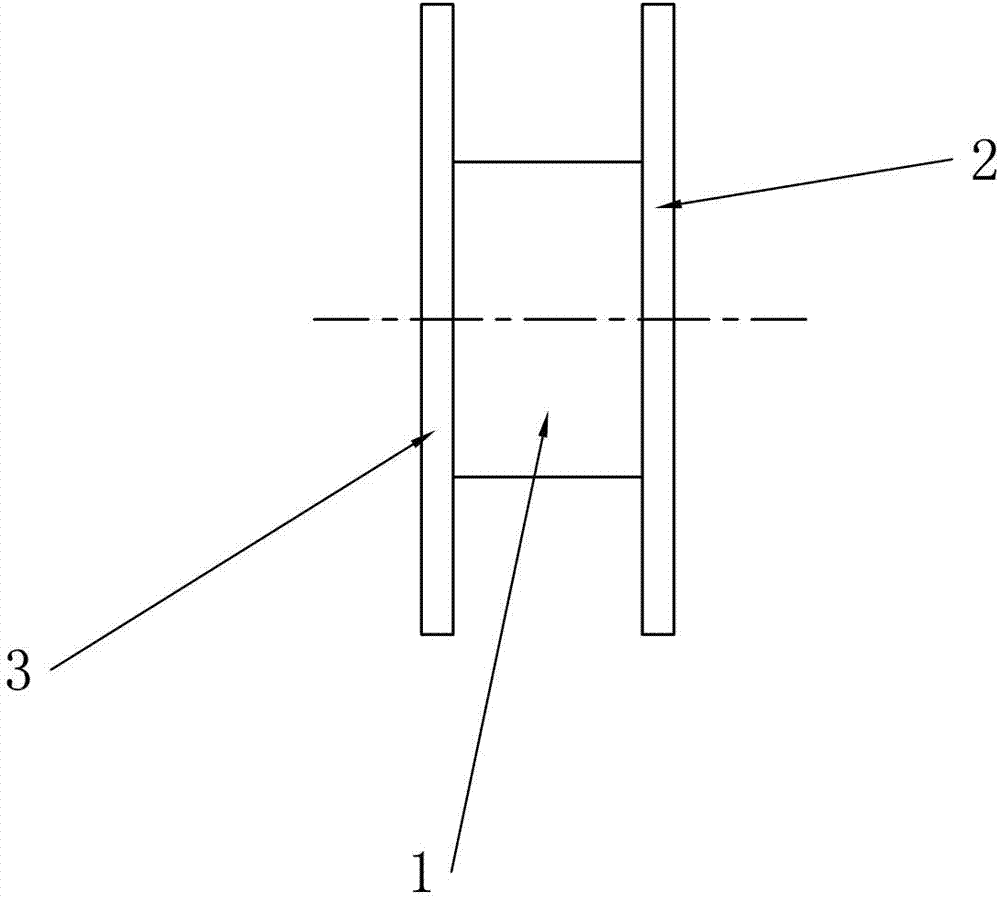

[0018] Implementation mode one: if figure 1 and 2 As shown, the spool with a handle of the present invention includes a connecting body 1 and a disc body arranged on the connecting body 1, and the above-mentioned disc body includes an upper disc body 2 and a lower disc body 3 respectively arranged at both ends of the connecting body 1, Wherein, the above-mentioned disc body is provided with a handle 4, and the handle 4 is provided with a handle hole 5, and the above-mentioned handle 4 is integrated with the disc body.

[0019] The handle 4 is arranged on the upper disc body 2; the disc body is generally cylindrical, the handle 4 is arranged on the outer wall of the disc body, and the handle 4 accounts for 1 / 4 of the circumference of the outer wall of the disc body, that is, the handle 4 occupies the range of 0° to 90° tangent orthogonal to the outer circle of the disk; a cut-off line 6 is provided at the joint between the handle 4 and the disk body.

[0020] In this embodime...

Embodiment approach 2

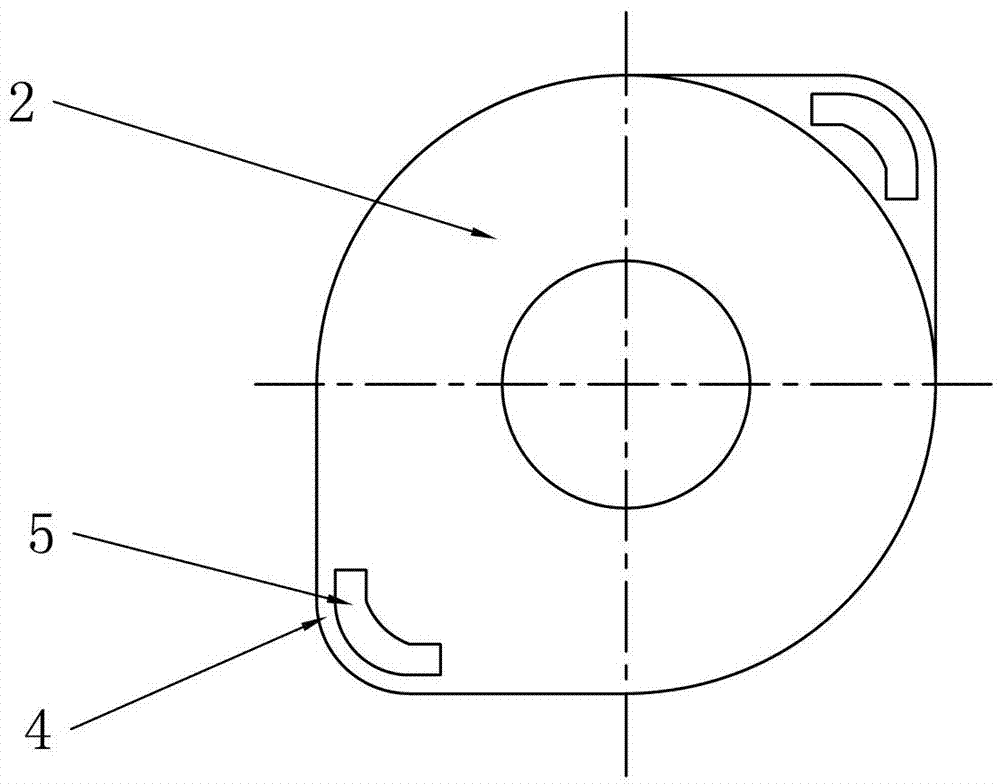

[0023] Implementation mode two: if image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the carrying handles 4 of this embodiment are respectively arranged on the upper plate body 2 and the lower plate body 3, and their positions form a diagonal form, which facilitates the delivery of cables When rotating and anti-rotating, and in conjunction with the selection of the user's habit of left-handed or right-handed work, the handle 4 of this embodiment is made into one with the upper disc body 2 and the lower disc body 3, and the handle 4 and the upper disc body 2 are integrated. There is no cut-off line 6 between them. When placed, no matter in which direction the spool rolls, the handle 4 can effectively prevent the roll from rolling.

Embodiment approach 3

[0024] Implementation mode three: if Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that there are two carrying handles 4 in this embodiment, and they are all arranged on the lower plate body 3, and at the same time, their positions form a diagonal form, that is, the lower plate The top surface of the body 3 is a reference and forms a coordinate system, and the center positions of the two handles 4 are set at 45° and 225° of the coordinate system.

[0025] This embodiment is the same as Embodiment 2 in that the handle 4 and the lower tray body 3 are integrated, and there is no trimming line 6 between the handle 4 and the lower tray body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com