Chiral mesoporous carbon nanometer fiber and preparation method of chiral mesoporous carbon nanometer fiber

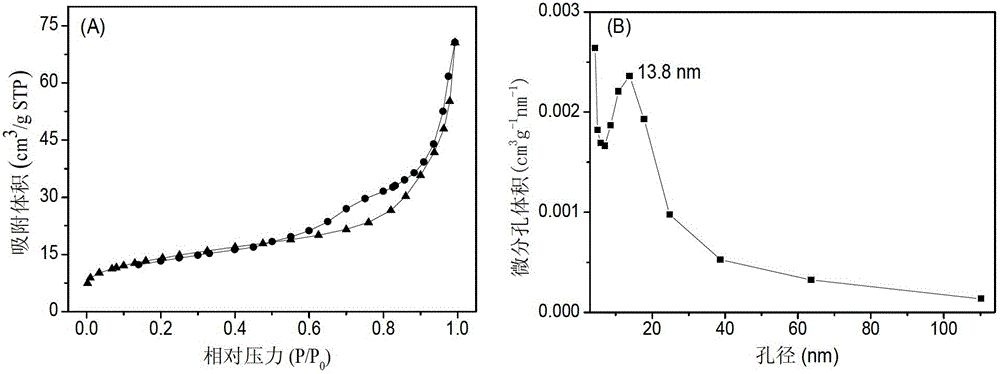

A technology of nanofiber and porous carbon, applied in the field of materials, to achieve the effect of large specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

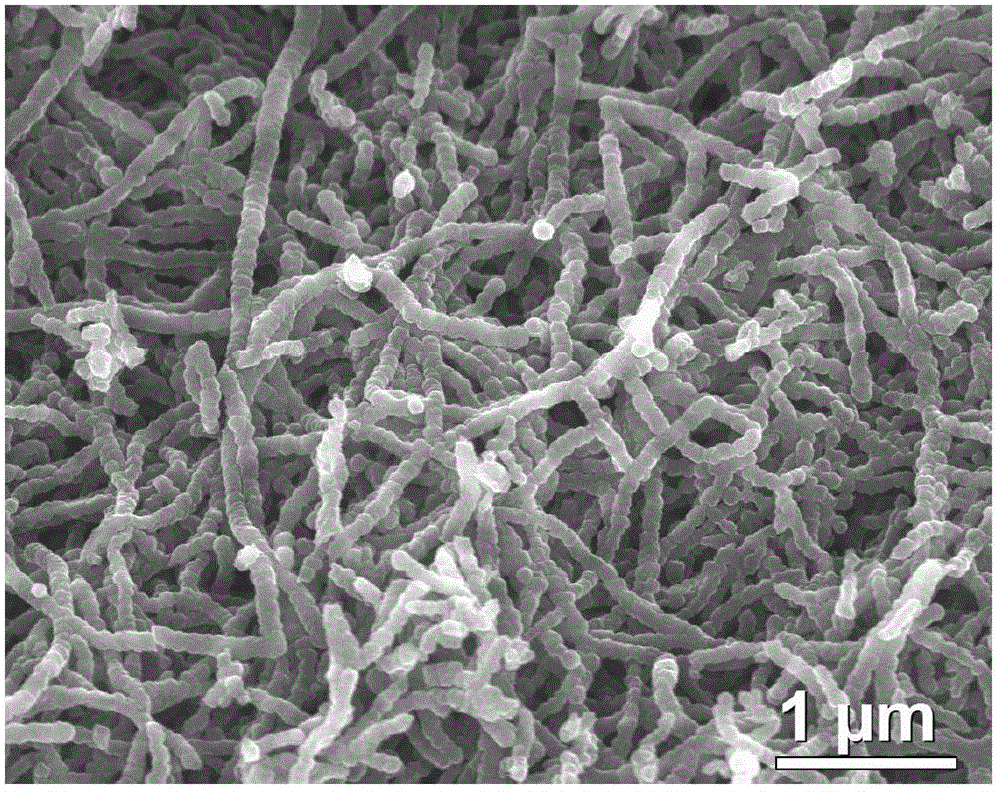

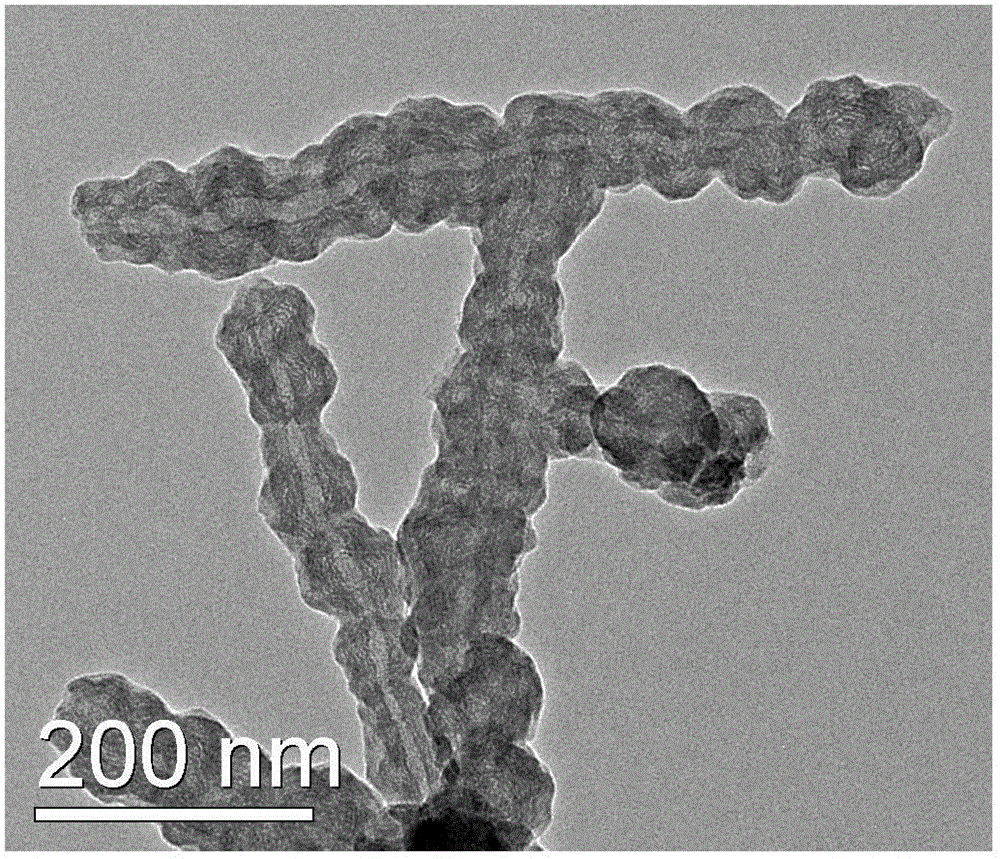

[0028] The quality is 0.014g N-myristoyl L-glutamic acid (N-myristoyl L-glutamic acid is self-synthesized according to the literature, and the literature is: (1) J.Am.Oil Chem.Soc.1972, 49, 157. Or (2) Fan Zhaxing, Synthesis and Mechanism of Chiral Mesoporous Conductive Polymers, Shanghai Jiaotong University Master Dissertation, 2008) was added to 8ml of ethanol and fully dissolved at 60°C; followed by adding 40ml of deionized water and 0.55ml of pyrrole monomer were placed in an ice-water bath and stirred for 20 minutes; then 7.2ml of 1M HCl and persulfuric acid obtained by dissolving 1.824g of ammonium persulfate in 4ml of water that had been pre-cooled to 0~5°C were added Ammonium aqueous solution, then magnetically stirred in an ice-water bath for 1 h, filtered under reduced pressure, and washed alternately with water and ethanol until the filtrate was close to neutral, and the filtered and washed product was dried in a vacuum oven at 50°C for 24 h to obtain chiral Porous ...

Embodiment 2

[0034] Add 0.014g of N-myristoyl L-glutamic acid into 8ml of ethanol and fully dissolve at 60°C; then add 40ml of deionized water and 0.55ml of pyrrole monomer respectively, place in an ice-water bath and stir for 10min Then add 7.2ml 1M HCl and the 4.973g ferric chloride hexahydrate solution which is pre-cooled to 0 ~ 5 ℃ and dissolve the ferric chloride hexahydrate aqueous solution obtained in 2ml water, and magnetically stir the reaction in an ice-water bath for 0.5h, Filtrate under reduced pressure, and alternately wash with water and ethanol until the filtrate is close to neutral. The filtered and washed product is dried in a vacuum oven at 50°C for 24 hours to obtain a chiral mesoporous carbon nanofiber precursor. The obtained chiral mesoporous carbon nanofiber precursor was heated to 800°C at a heating rate of 3°C / min under a nitrogen atmosphere with a flow rate of 400ml / min, carbonized at a constant temperature for 3h, and naturally cooled to room temperature to obtain ...

Embodiment 3

[0038] Add 0.014g of N-myristoyl L-glutamic acid into 8ml of ethanol and fully dissolve at 60°C; then add 40ml of deionized water and 0.55ml of pyrrole monomer respectively, place in an ice-water bath and stir for 20min Add 7.2ml of water and 4.973g of ferric chloride hexahydrate dissolved in 4ml of water to obtain 7.2ml of water and 4.973g of ferric chloride hexahydrate, respectively, and react with magnetic stirring for 3h in an ice-water bath, and decompress Filter and wash alternately with water and ethanol until the filtrate is close to neutral. The filtered and washed product is dried in a vacuum oven at 50° C. for 24 hours to obtain a chiral mesoporous carbon nanofiber precursor. The obtained chiral mesoporous carbon nanofiber precursor was heated to 900°C at a heating rate of 5°C / min under a nitrogen atmosphere with a flow rate of 100ml / min, carbonized at a constant temperature for 5h, and naturally cooled to room temperature to obtain chiral mesoporous carbon nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com