Manufacturing method of spiral separation column and equipment for realizing method

A manufacturing method and spiral technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of uniform control and difficult filling density, and achieve the effect of uniform spiral shape, avoidance of deformation, and avoidance of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing a helical separation column, the steps are as follows,

[0049] First seal and fix the head end of the first raw material pipe on the mould, and then inject filler at the tail end of the first raw material pipe.

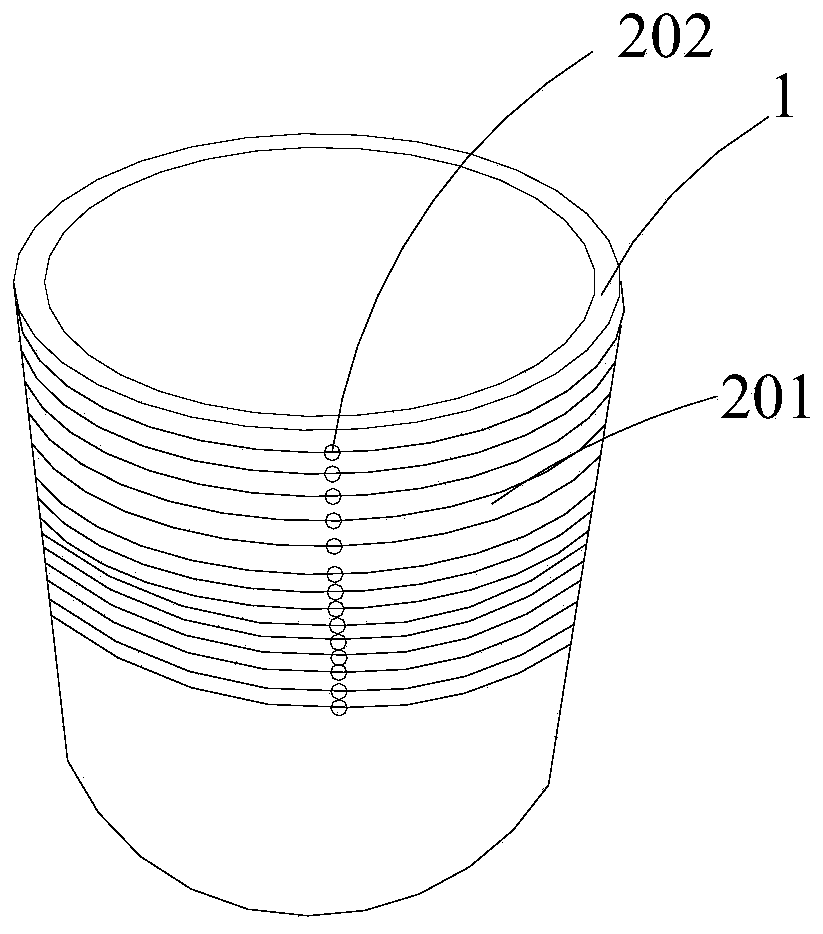

[0050] Wrap the first raw material tube on the mould, and shape it into a helical shape; form several turns of threads, and connect adjacent threads together.

[0051] Connect the head end of the second material pipe to the tail end of the first material pipe to form a connected pipeline. Check the tightness of the connection points. After meeting the airtightness requirements, pour filler into the end of the second raw material pipe, and compact the filler in the pipe with high-pressure nitrogen. Wrap the second raw material tube on the mould, and shape it into a helical shape; form several turns of threads, and connect adjacent threads together.

[0052] According to this method, the third to the Nth raw material pipes are sequent...

Embodiment 2

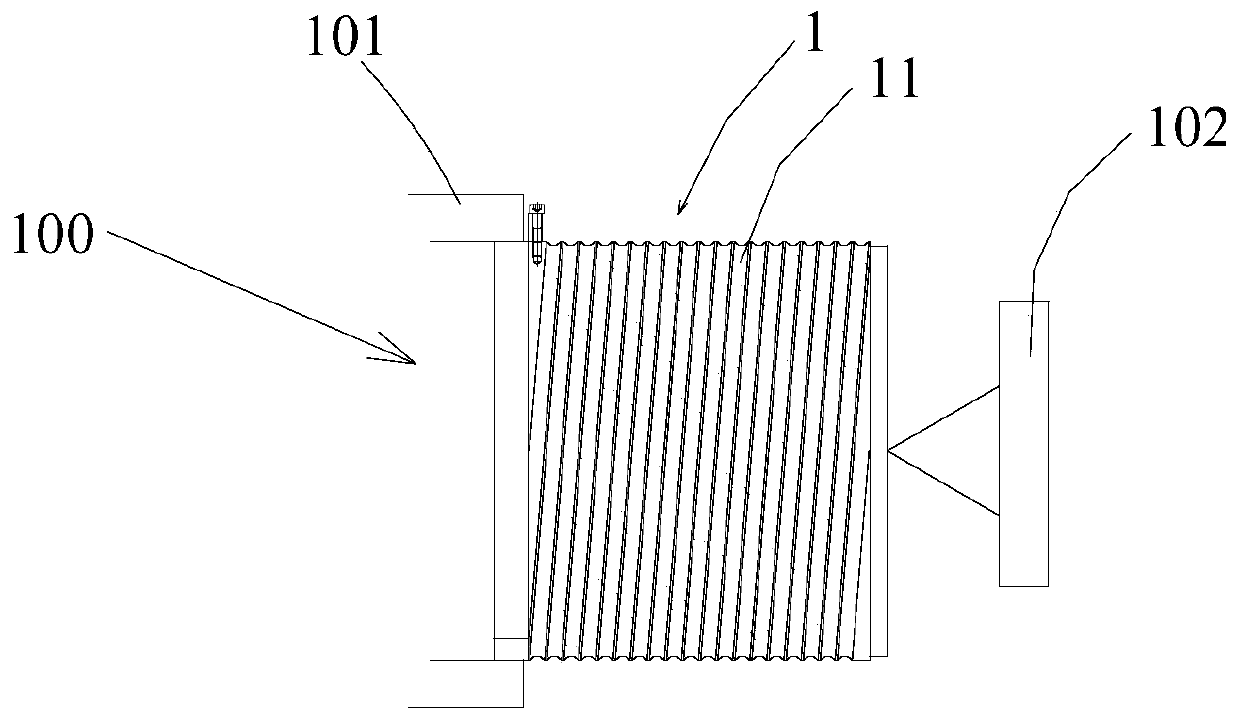

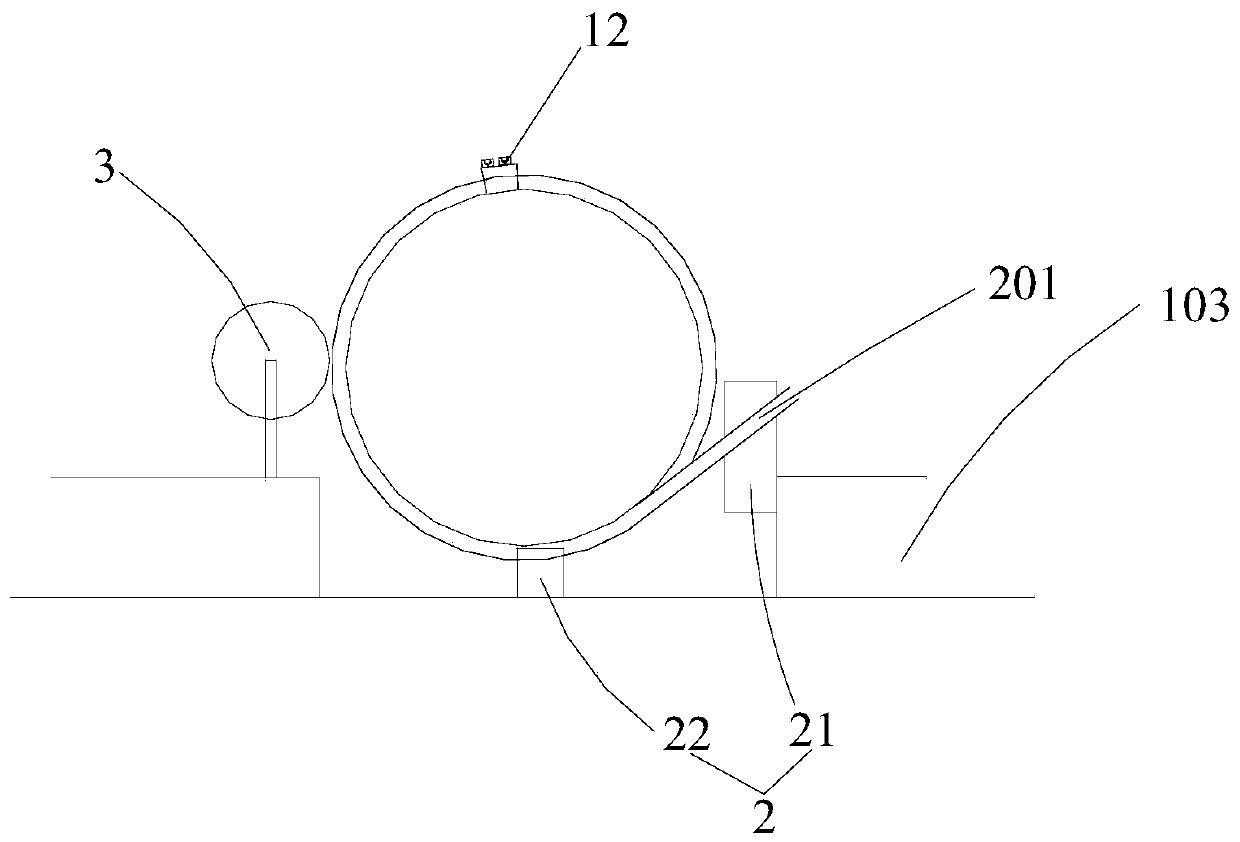

[0055] The present invention provides a kind of equipment that realizes above-mentioned method, such as Figure 1-2 As shown, the equipment includes a machine tool 100 , a spiral mold 1 , and a pipe holder 2 ; It is used to drive the spiral mold 1 to rotate; the spiral mold 1 is fixed on the machine tool through the machine tool faceplate 101 and the machine tool tailstock 102, and the spiral mold 1 is matched with the spiral separation column; the spiral tire A tool is provided with a spiral groove 11, and the spiral groove 11 is matched with the spiral separation column. The spiral mold 1 is provided with a fixing device 12, and the fixing device 12 is used to fix the head end of the raw material pipe; the pipe clamp 2 includes a first pipeline clamp 21 and a second pipeline clamp Device 22. The first pipeline clamper 21 is fixed on the tool rest 103 of the machine tool and is located on the side of the spiral mold; the second pipeline clamper 22 is fixed on the tool rest ...

Embodiment 3

[0060] In this embodiment, the equipment in Embodiment 2 is used to realize a manufacturing method of a helical separation column. The raw material pipe is a seamless stainless steel pipe.

[0061] The first raw material pipe is fixed on the spiral mold 1 through the counterbore. After the fixing is completed, the first raw material pipe is filled with filler, and after filling, the entrance is sealed by the head to prevent the filler from spilling.

[0062] The rotation of the machine tool 100 drives the spiral mold 1 to rotate, and the first raw material tube is wound on the spiral mold to complete the winding of the first raw material tube, leaving a certain length at the tail end to facilitate the connection with the next raw material tube. welding. After welding with the next raw material pipe, leak detection is carried out by high-pressure inert gas, and at the same time, the high-pressure gas can further compact the filler in the pipe. Repeat the above steps until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com