Composite core drill bit

A compound drill bit and core cutting technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., can solve the problems of low work efficiency, large wear of the drill bit, short life of the drill bit, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

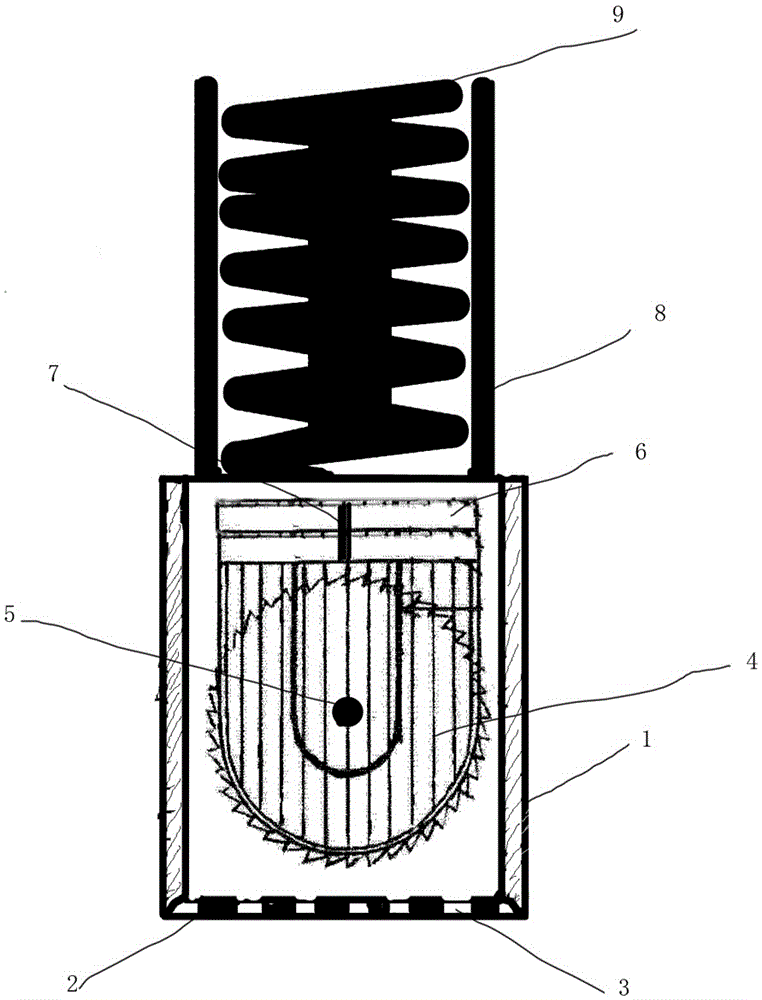

[0021] The core-cutting composite drill bit includes: a drill part, a core-cutting part, and a broken core part.

[0022] The drill head is in the shape of an annular tube, and is provided with a plurality of rotatable drill teeth. The drill teeth are made of superhard material and provided with a water outlet.

[0023] The teeth are arranged to secure the head end of the barrel drill.

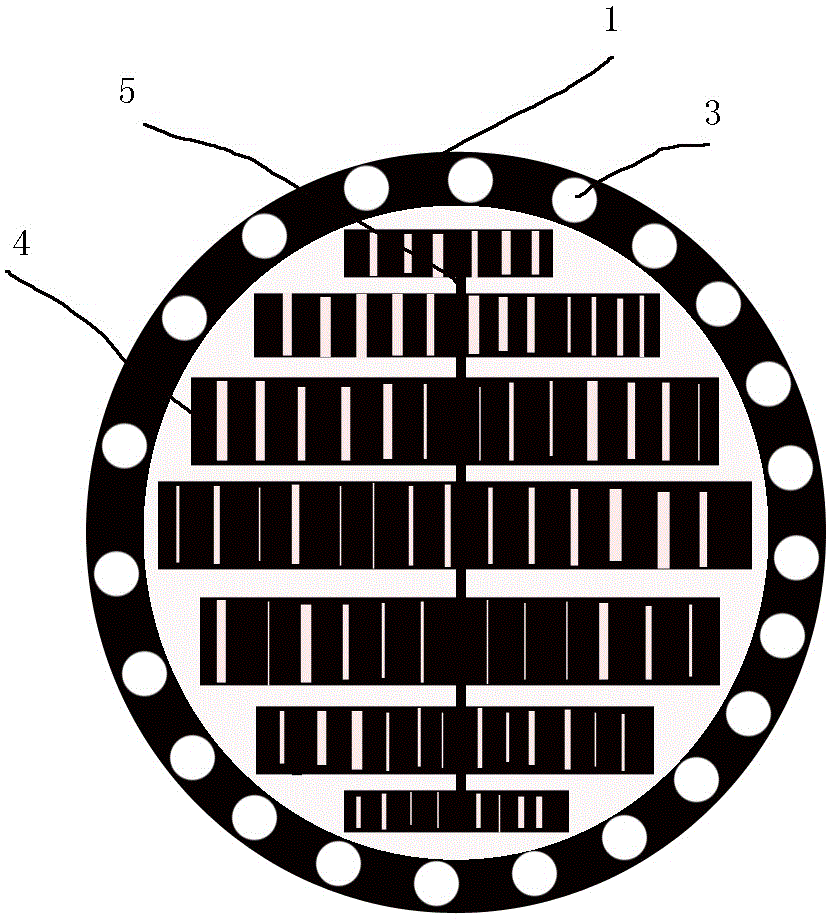

[0024] The core-cutting part is composed of 1-20 saw blades arranged side by side, and is driven to rotate vertically by a bearing.

[0025] The broken core part is composed of upper and lower two large grinding discs. The upper grinding disc is distributed with 1-30 holes. The upper part of the hole is larger than the lower one. Grinding, the crushed powder or small particles are transferred out of the wellhead by the screw rod.

[0026] The drill part is surrounded by the drill part at the outer core cutting part and is indented by 3-30 cm.

[0027] The broken core part is on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com