Self-leveling glazed ultrathin mirror polishing ceramic plate and manufacturing method thereof

A technology of mirror polishing and manufacturing method, which is applied to clay products, other household utensils, household utensils, etc., to achieve the effect of broadening the scope of application, ensuring consistency, and reducing the cost of glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

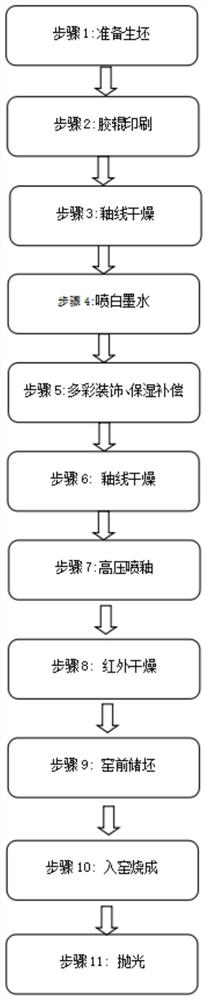

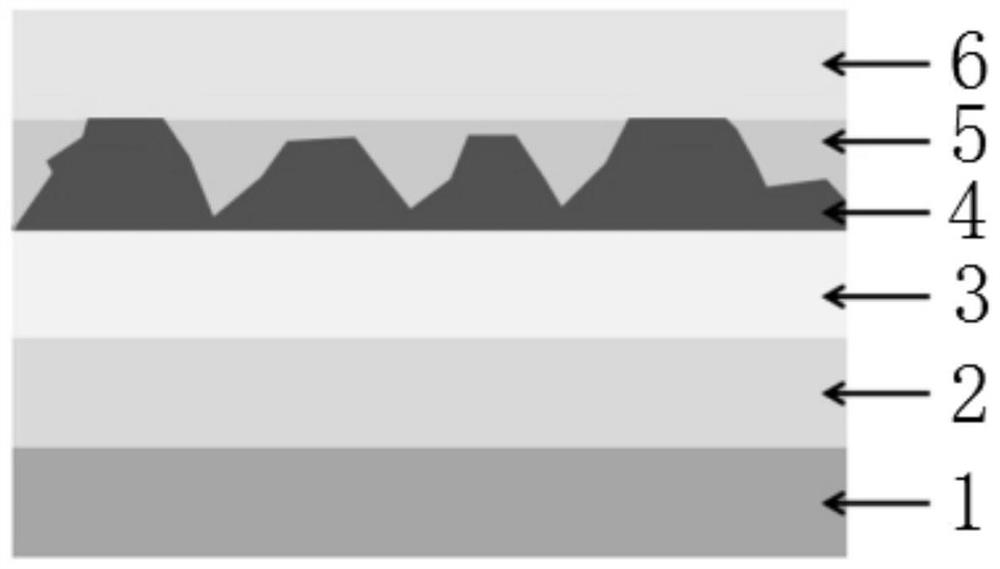

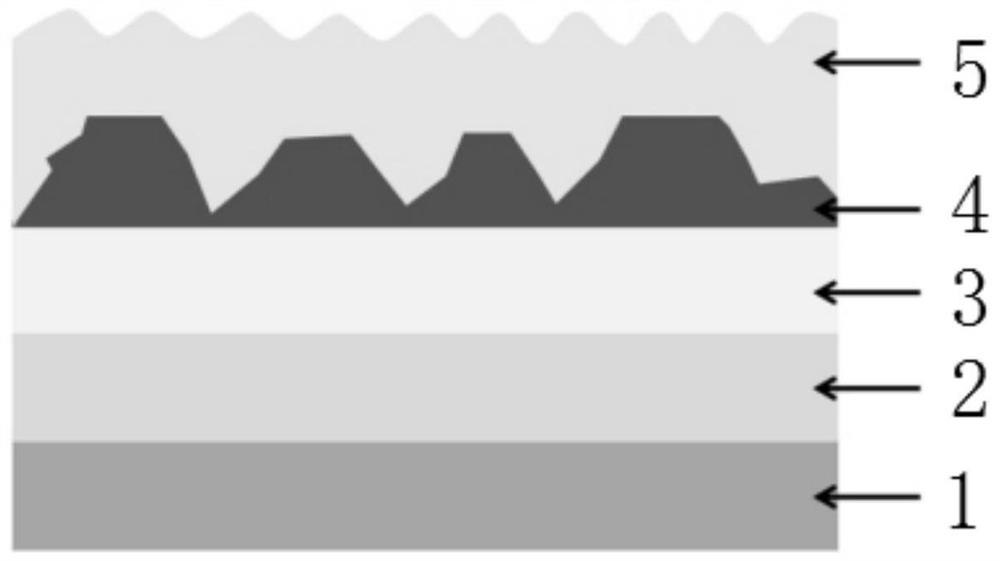

[0034]A manufacturing method of a self-leveling glaze decorated ultra-thin mirror-polished ceramic plate includes the following steps:

[0035]1) Prepare green body 1;

[0036]2) Rubber roller printing: Two rubber rollers are used to print high-white clay on the surface of the ultra-thin green body 1 to form the base glaze layer 2, and then the semi-finished product A is obtained; wherein the rubber roller flower glaze has a specific gravity of 1.35 and the combined glaze amount is less than 100g / m2, The temperature before the rubber roller is lower than 45℃;

[0037]3) Drying of the glaze line: The temperature of the semi-finished product A is compensated in time through the glaze line drying to obtain the semi-finished product B, and the temperature is controlled between 60 ℃ during drying;

[0038]4) Spray digital white ink: use 2 channels to large-area inkjet printing white ink on semi-finished product B to form digital glaze layer 3, and then semi-finished product C is obtained;

[0039]5) A...

Embodiment 2

[0055]A manufacturing method of a self-leveling glaze decorated ultra-thin mirror-polished ceramic plate includes the following steps:

[0056]1) Prepare green body 1;

[0057]2) Rubber roller printing: Two rubber rollers are used to print the high-white makeup soil on the surface of the ultra-thin green body 1 to form the base glaze layer 2, and then the semi-finished product A is obtained; the rubber roller flower glaze has a specific gravity of 1.36 and the combined glaze amount is less than 100g / m2, The temperature before the rubber roller is lower than 45℃;

[0058]3) Glaze line drying: The temperature of semi-finished product A is compensated in time through glaze line drying to obtain semi-finished product B, and the temperature during drying is controlled between 100°C;

[0059]4) Spray digital white ink: use 3 channels to inkjet print white ink on semi-finished product B on a large area to form digital glaze layer 3, and then semi-finished product C is obtained;

[0060]5) The semi-finis...

Embodiment 3

[0076]A manufacturing method of a self-leveling glaze decorated ultra-thin mirror-polished ceramic plate includes the following steps:

[0077]1) Prepare green body 1;

[0078]2) Rubber roller printing: Three rubber rollers are used to print high white clay on the surface of the ultra-thin green body 1 to form the base glaze layer 2, and then the semi-finished product A is obtained; the rubber roller flower glaze has a specific gravity of 1.38 and the combined glaze amount is less than 100g / m2, The temperature before the rubber roller is lower than 45℃;

[0079]3) Drying of glaze line: The temperature of semi-finished product A is compensated in time through glaze line drying to obtain semi-finished product B, and the temperature is controlled between 145°C during drying;

[0080]4) Spray digital white ink: use 4 channels to inkjet print white ink on semi-finished product B on a large area to form digital glaze layer 3, and then semi-finished product C is obtained;

[0081]5) After the semi-finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com