Low-temperature scouring and bleaching agent and application thereof

A low-temperature refining and bleaching agent, scouring and bleaching technology, used in bleaching products, textiles and papermaking, dry cleaning fiber products, etc., can solve the problems of environmental protection and high dosage of additives, reduce costs, shorten the treatment process, and reduce sewage treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-temperature scouring and bleaching agent, which specifically includes the following components: 90g of anhydrous sodium metasilicate (powder, sodium oxide 50.5 ± 1%, Qingdao Jiarun Chemical Co., Ltd.), 360g of pentahydrate sodium metasilicate (granule, oxidized Sodium 28.5~30%, Qingdao Jiarun Chemical Co., Ltd.), sodium percarbonate 135g (granule, active oxygen ≥13%, Henan Hongye Biochemical Co., Ltd.), soda ash 225g (content 99.8%, Weifang Ruidesheng Chemical Co., Ltd. ), caustic soda 18g (content 96%, Zibo Xuhang Chemical), XP-90 36g (isomeric C10 ethoxylate, BASF), S-60 36g (sorbitan fatty acid ester, Jiangsu Haian Petrochemical ), dicyandiamide 100g (content ≥ 98%, Henan Yuxiang Chemical);

[0035] Its preparation process is as follows: after mixing various raw materials according to the above formula, fully stirring, and then packing, moisture-proof should be paid attention to during packing and storage.

Embodiment 2

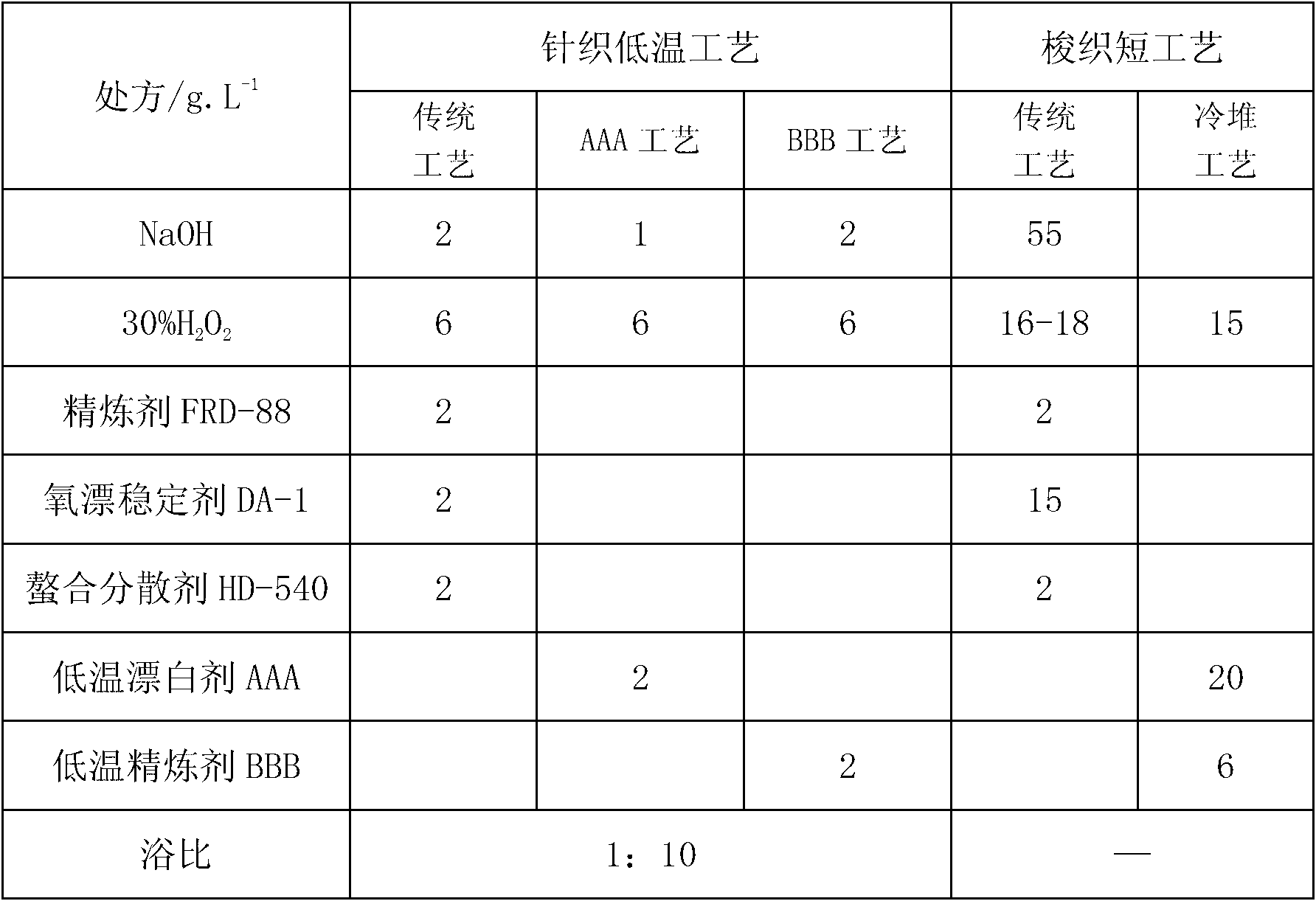

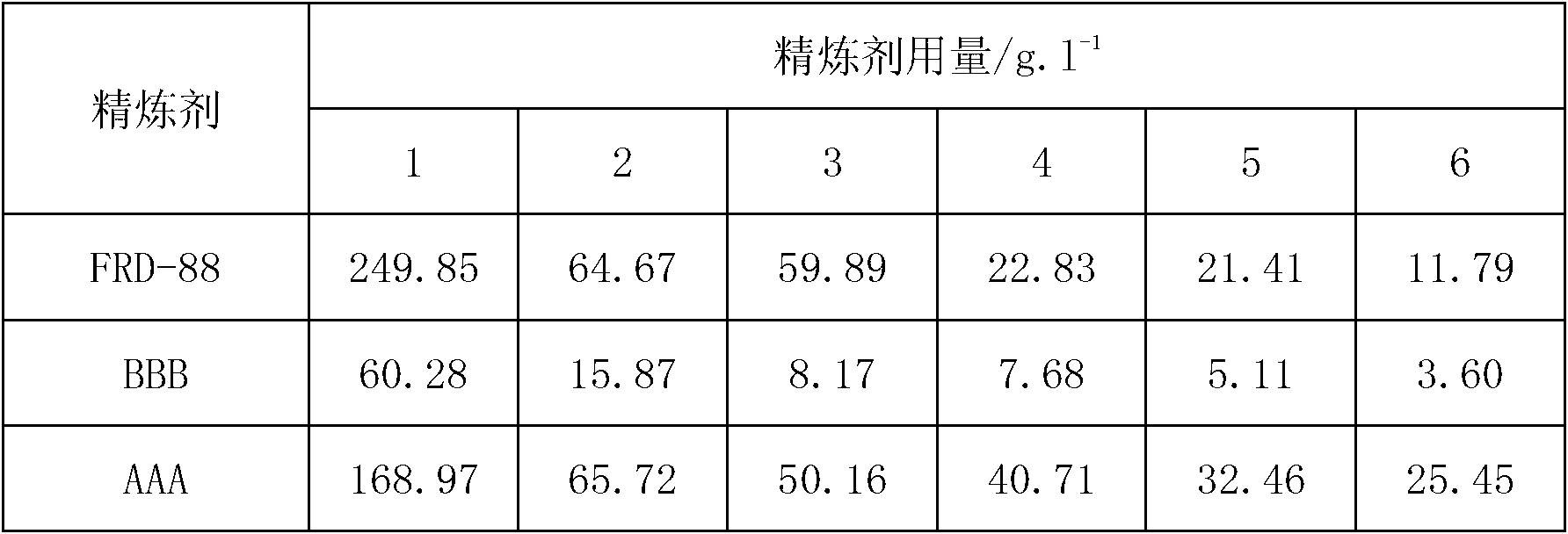

[0037]The low-temperature, low-alkali and short-process pretreatment process for cotton and its blended fabrics is suitable for conventional knitted fabrics. The steps include:

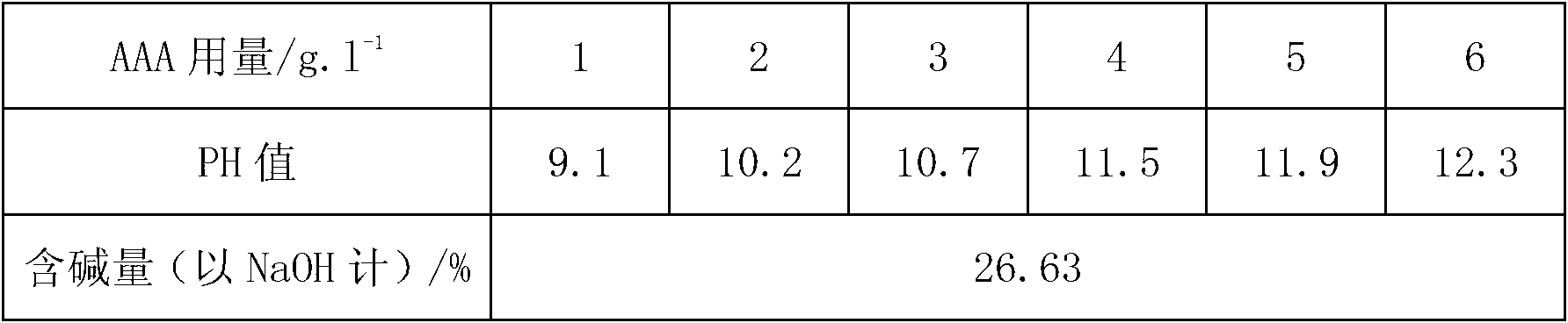

[0038] A. Scouring and bleaching: Cotton and its blended fabric gray cloth are scoured and bleached for 60 minutes in 80° C. boiling and bleaching working solution; wherein, the formula of the boiling and bleaching working solution is: the low-temperature scouring and bleaching agent 2.0 g / L of Example 1, NaOH 1 g / L, H with a volume fraction of 30% 2 o 2 6g / L, the rest is water;

[0039] B. Cold washing and drying: the product obtained in the previous step can be washed with cold water and dried.

Embodiment 3

[0041] The low-temperature, low-alkali and short-process pretreatment process for cotton and its blended fabrics is suitable for light and thin plain and corduroy conventional knitted fabrics. The steps include:

[0042] A. Low-temperature stacking: Cotton and its blended fabric gray cloths are soaked in the boiling and bleaching working solution, the excess rate is 110%, and they are stacked at 40°C for 10h to 12h; wherein, the formula of the boiling and bleaching working solution is: the low-temperature bleaching solution in Example 1 Scouring and bleaching agent 20g / L, volume fraction of 30% H 2 o 2 12g / L~13g / L, low temperature scouring agent 6g / L~8g / L, and the rest is water; among them, the low temperature scouring agent specifically contains the following ingredients: Diacid X 25% (fatty acid derivatives, Shanghai Suokai Industrial Co., Ltd.), TO-7 15% (isomeric alcohol, Zhejiang Chuanhua Import and Export Co., Ltd.), XP-90 5% (isomeric alcohol, Jinchang Chemical Co., L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com