Manufacture method of regular hexagon castellated beam

A technology of regular hexagon and manufacturing method, applied in the direction of joists, girders, trusses, etc., can solve the problems of inability to increase the bearing capacity and rigidity of components, complicated manufacturing methods, etc., and achieve light weight, significant economic benefits, and improved rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] I-beams are generally used for profiles. When the section height of the designed beam is 360mm, use No. 18 I-beams, which saves a lot of cost than using No. 36 I-beams. (The web height of 18 gauge I-beam is 180 mm).

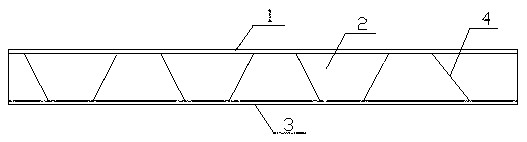

[0022] Such as Figure 4 The shown honeycomb beam with regular hexagonal holes with a height of 360 mm includes an upper flange 1 , a lower flange 3 and a plurality of regular hexagonal holes on the web 2 . When the upper and lower flange widths required by the design are the same as the upper and lower flange widths, thicknesses and web thicknesses of No. 18 I-beams or No. 18 H-beams, you can use No. 18 I-beams or No. 18 H It is not necessary to drill holes on No. 36 I-beam or No. 36 H-beam with the same width, thickness and web thickness of the upper and lower flanges.

[0023] Its preparation method is carried out as follows:

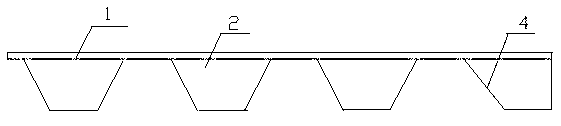

[0024] 1) if figure 1 As shown, draw three parallel lines at the web of the I-shaped steel beam, two of which are at the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com