Extra-long working surface fully mechanized coal mining process

A technology of working face and fully mechanized mining face, which is applied in surface mining, mining equipment, earth-moving drilling, etc. to achieve the effect of improving service life, prolonging emergency time, and reducing the number of house moves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

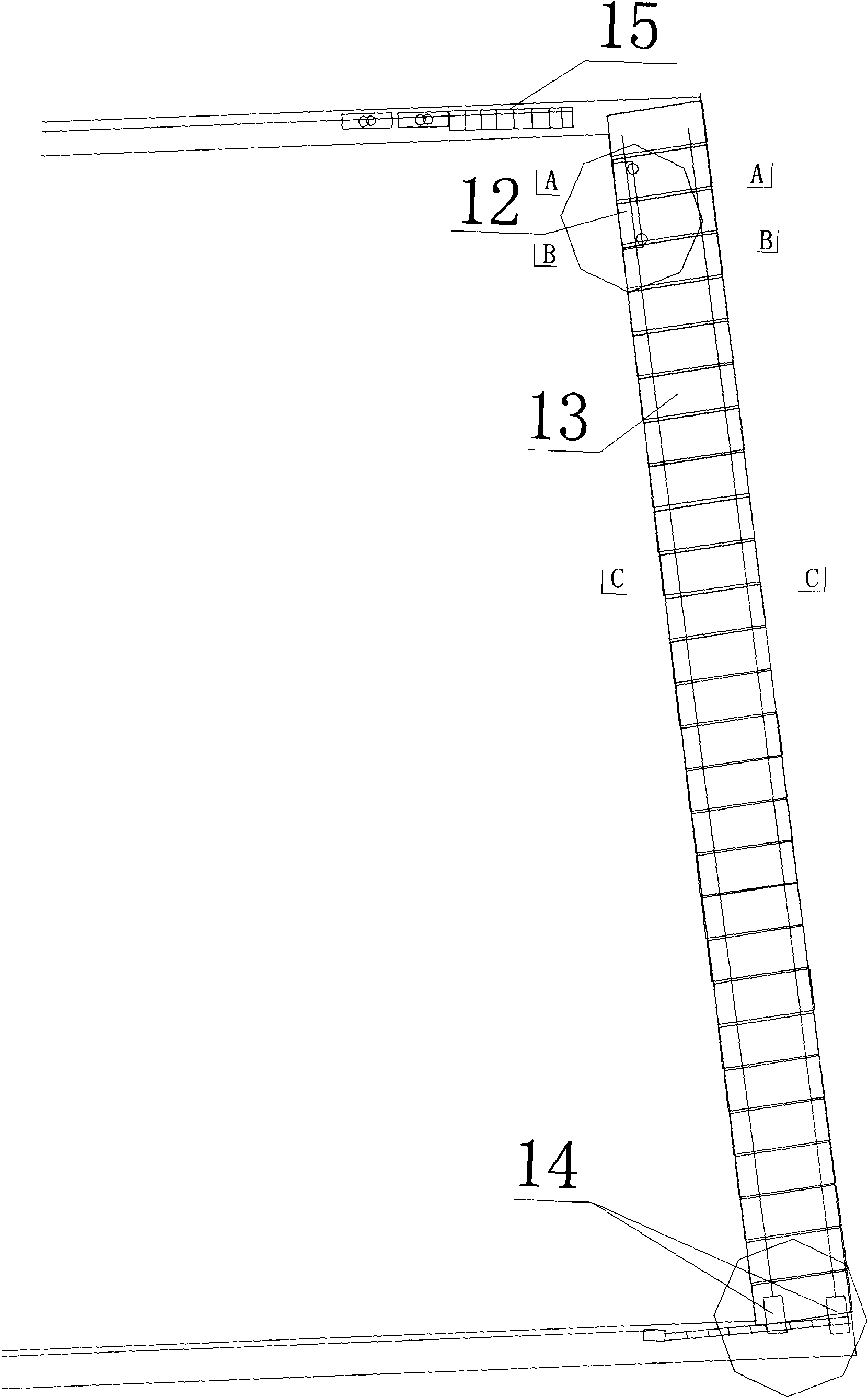

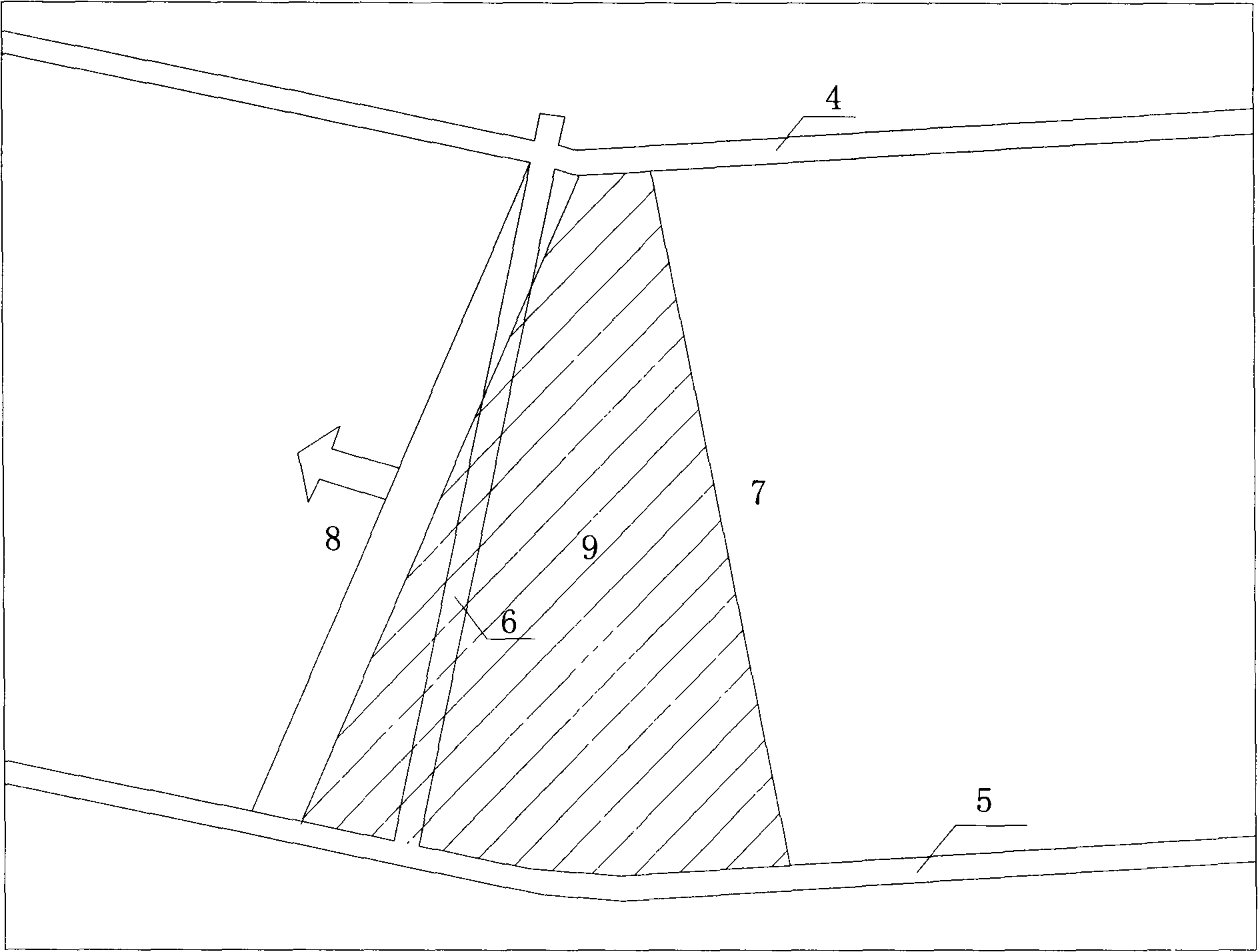

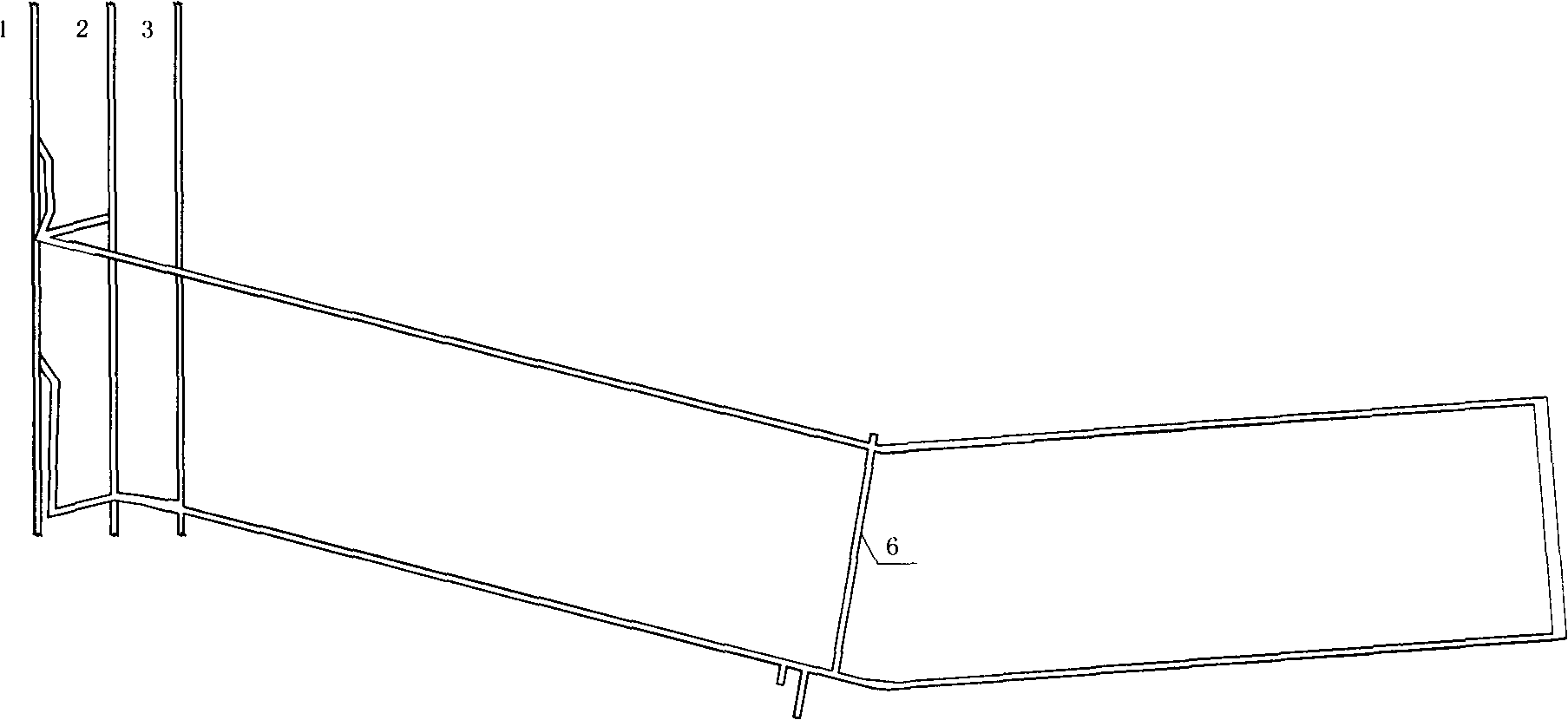

[0024] Excavate the up and down parallel grooves 4 and 5 to 1500-3000 meters respectively, and when driving to about 1500 meters, open the connecting lane 6 at the upper and lower parallel grooves 4 and 5. The upper troughs 4 and 5 are used as machinery, materials, personnel and air intake passages, and the lower troughs 5 are used as transport passages and air return lanes according to the telescopic belt conveyor. During the advancing process of the working face, the working face crossed the inflection point and crossed the connecting lane 6 at the same time, the adjustment of the working face and the difficulty of the roof pressure. In order to solve the above difficulties, the fan-shaped mining process was adopted to increase the pseudo bevel angle of the working face and reduce the advancing of the working face. Speed, during the propulsion process, firstly, the 1-10 frames at the lower end are used as the first group, and the mining face of this section is firstly advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com