Hose bundle

A hose and annular tube technology, applied in the field of hose bundles, can solve the problems of not being able to use multiple times, not being able to adjust the tightness of the tube bundle, and easy deformation of the tube bundle, and achieve the effects of not being easily deformed, elastically adjustable, and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

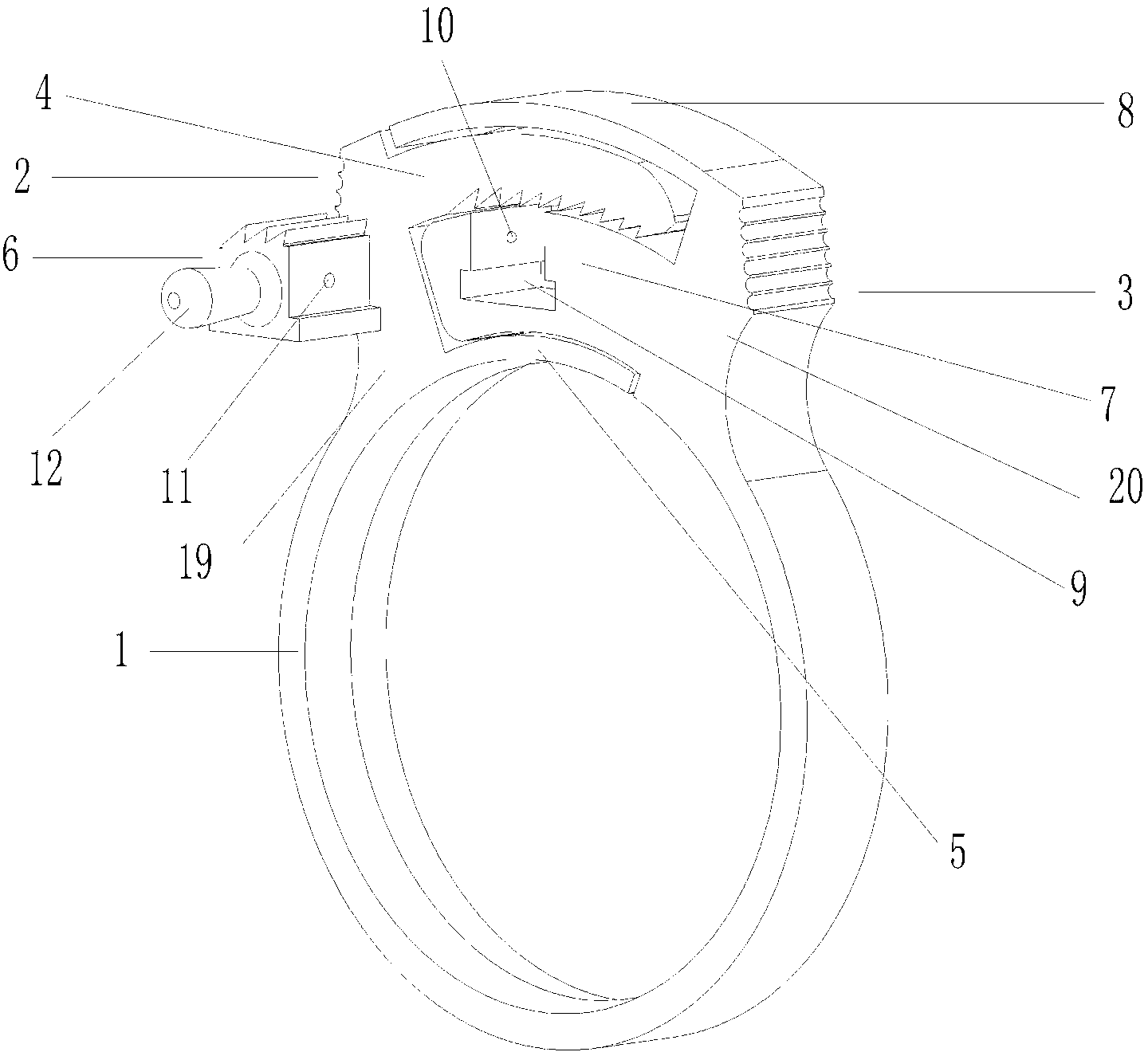

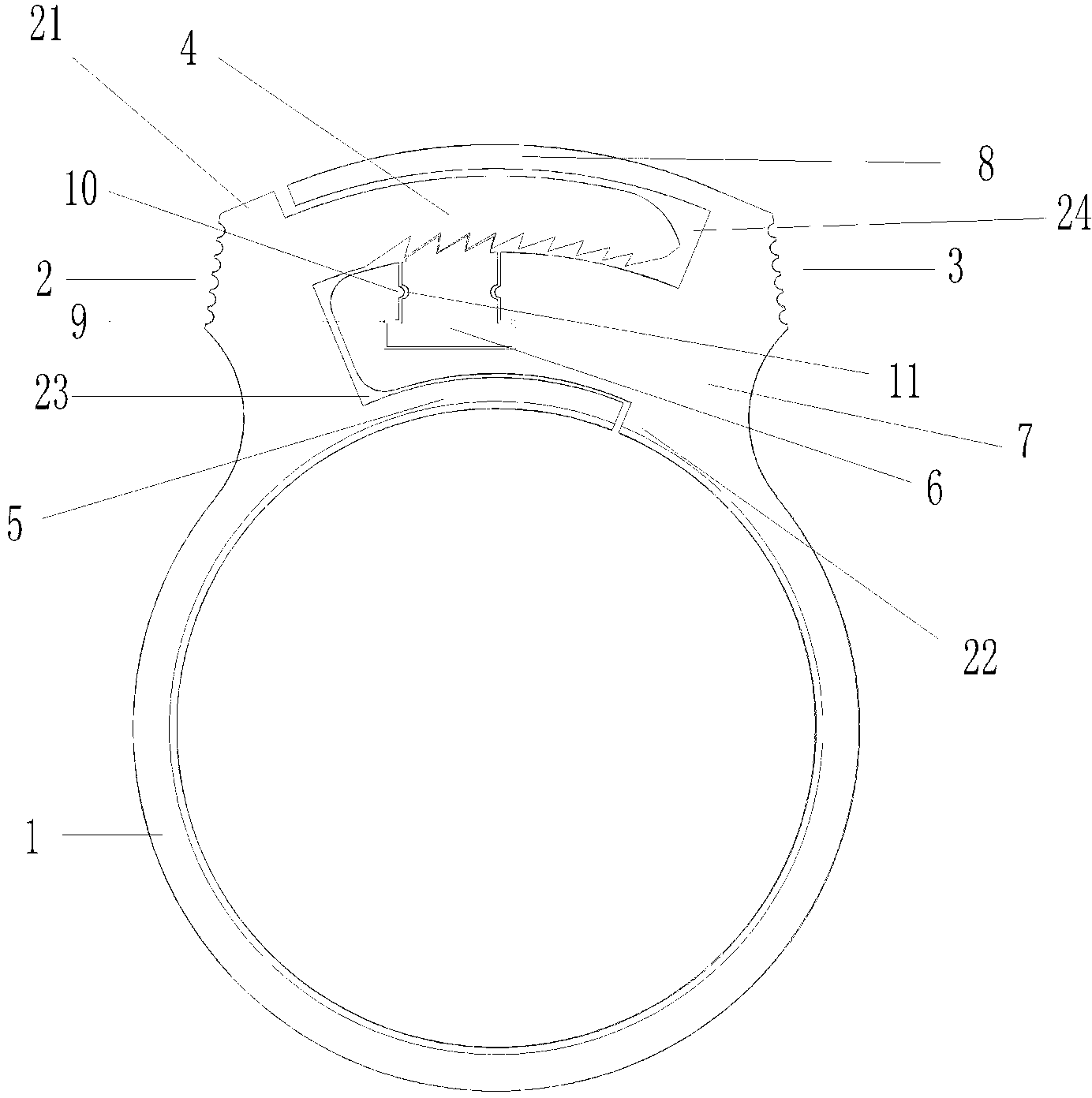

[0017] Such as figure 1 , figure 2 As shown, the hose bundle includes an annular pipe collar 1 with an open end and an interlocking part I 2 and an interlocking part II 3 that cooperate with each other;

[0018] Interlocking part I comprises auxiliary part I19, ratchet bar 4 and protruding ring I5, and ratchet bar and protruding ring I are fixed on one end of annular pipe hoop by auxiliary part I; Ratchet bar and protruding ring I are mutually parallel and keep setting A fixed gap I 23; the convex ring I is below, the ratchet bar is above, the ratchet of the ratchet bar is located on the lower surface, and the ratchet is facing the auxiliary part I;

[0019] Interlock part II includes protruding ring II 8, perforated protruding ring 7, locking piece 6 and auxiliary part II 20, protruding ring II and perforated protruding ring are fixed on the other end of the ring pipe collar through auxiliary part II; protruding ring II and perforated protruding ring are mutually Parallel ...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 lies in the hole protruding ring and the interlocking piece.

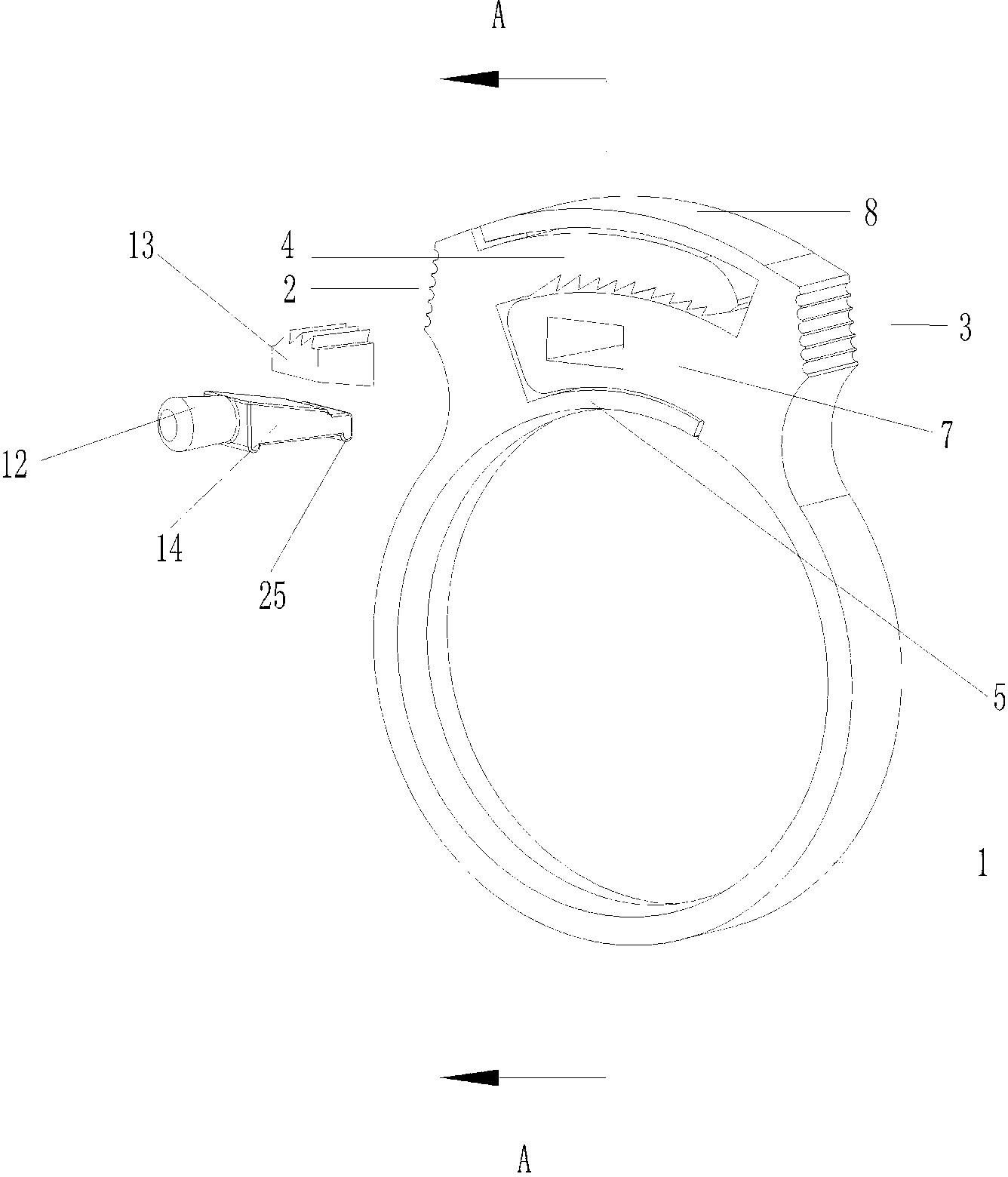

[0028] Such as image 3 and Figure 4 As shown, the interlocking part is composed of a ratchet part 13 and a push-pull part 14. The push-pull part is wedge-shaped, and its thick end is connected to the handle; the lower end surface of the ratchet part matches its upper end surface;

[0029] The installation hole in the perforated convex ring is composed of an axial installation hole 15 and a radial installation hole 16, the axial installation hole communicates with the radial installation hole, the axial installation hole cooperates with the push-pull part, and the radial installation hole cooperates with the ratchet part ;

[0030] A protruding part 25 is respectively arranged under the thick end and the thin end of the push-pull part, and they play the role similar to the convex point and the concave point in the first embodiment.

[0031] The oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com