Air-boosting hydraulically driven clutch execution mechanism

An actuator and clutch technology, applied in the direction of fluid drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problems of long system response time, incomplete clutch separation, low transmission efficiency, etc., to improve accuracy and response speed, The effect of improving wild survivability and good quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

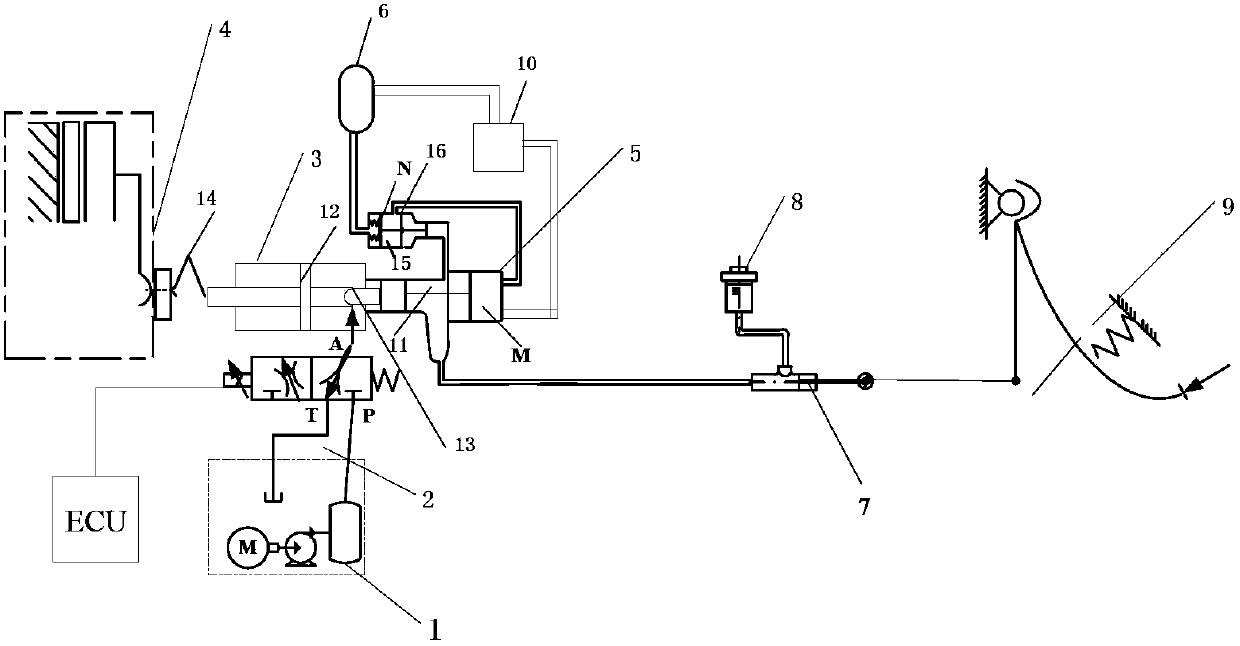

[0017] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

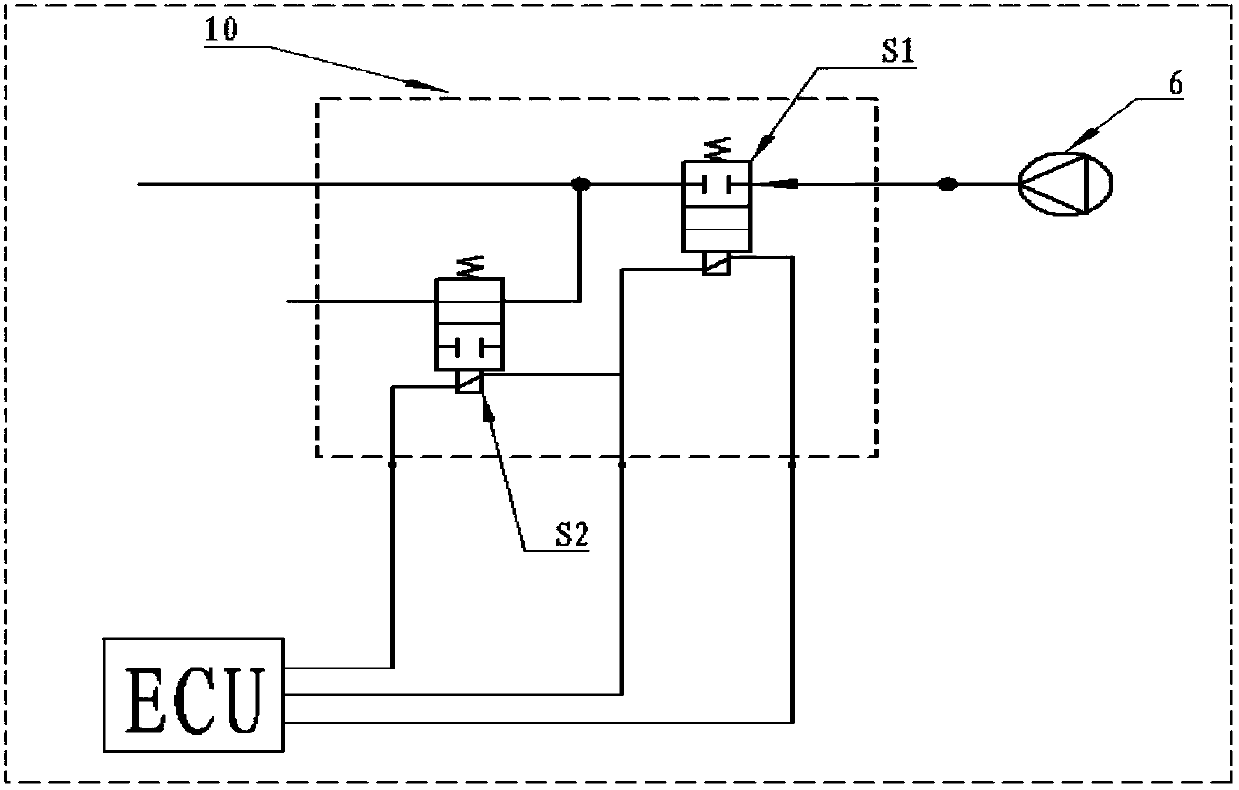

[0018] see figure 1 , the present invention provides a gas-assisted hydraulically driven clutch actuator, including a clutch automatic operating system and a clutch emergency system, wherein the clutch automatic operating system includes a hydraulic oil source 1, a proportional flow valve 2, a hydraulic working cylinder 3, a clutch 4, a clutch point Pump 5, air storage tank 6, air valve block 10, sub-pump working chamber 11, working cylinder piston 12, sub-pump ejector rod 13, separation shift fork 14, sub-pump right chamber M, sub-pump air valve N, of which hydraulic oil Source 1 is the oil source of the entire system, providing high-pressure hydraulic oil for the hydraulic working cylinder 3. The oil outlet of the hydraulic oil source 1 is connected to the oil inlet of the proportional flow valve 2 through the oil pipe, and the oil return port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com