Automatic steam and hot water converting system

An automatic conversion and steam technology, applied in steam generation, steam generation methods, water heaters, etc., can solve problems such as dry noise pollution, safety hazards, and coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

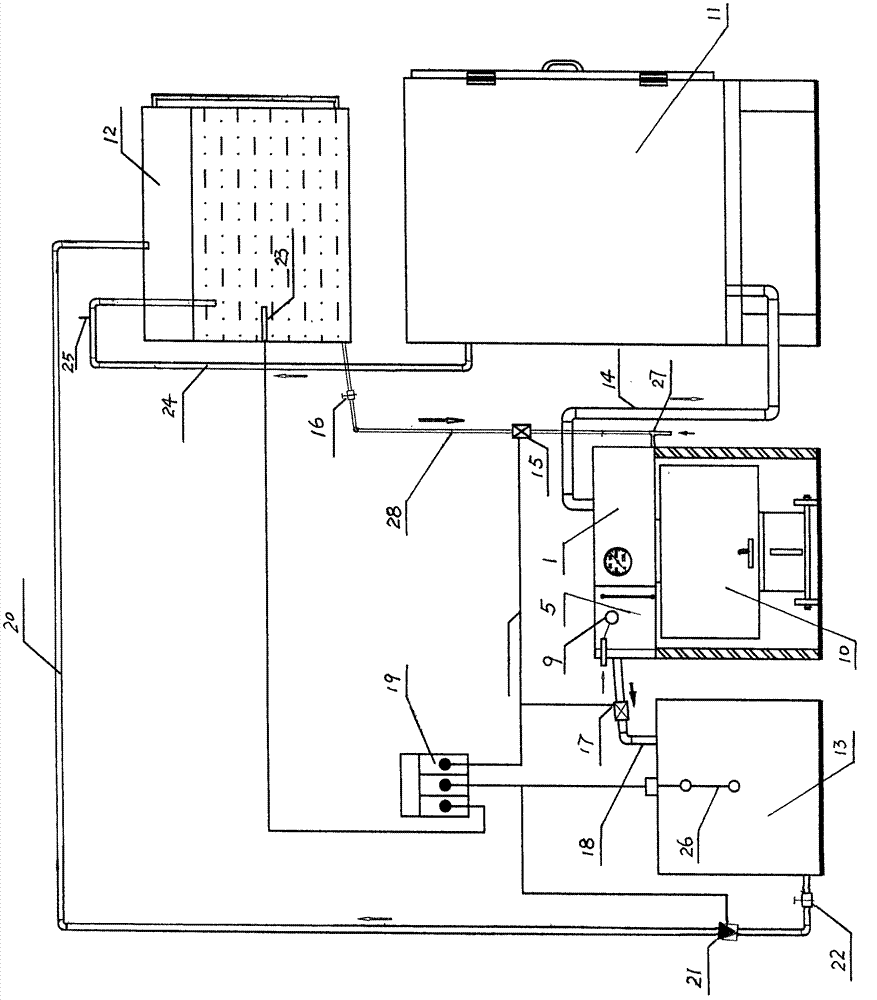

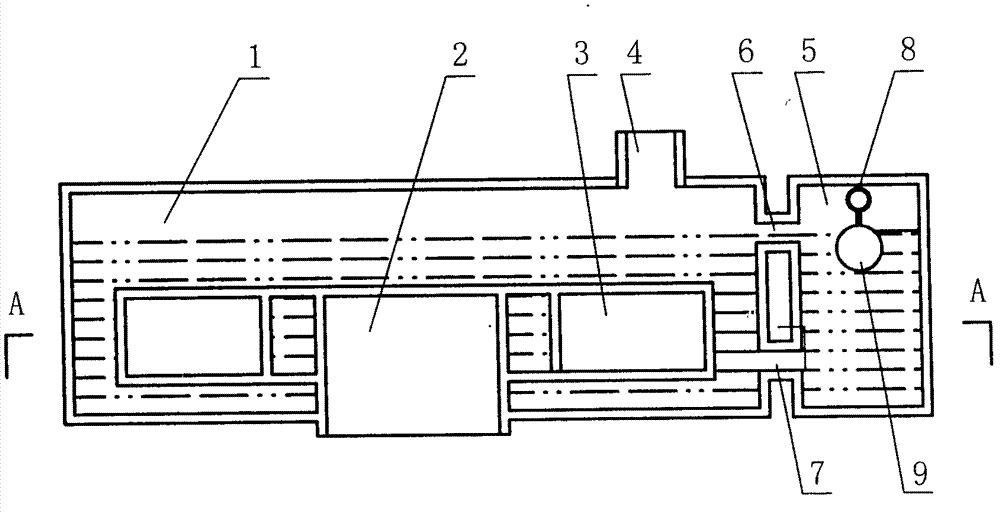

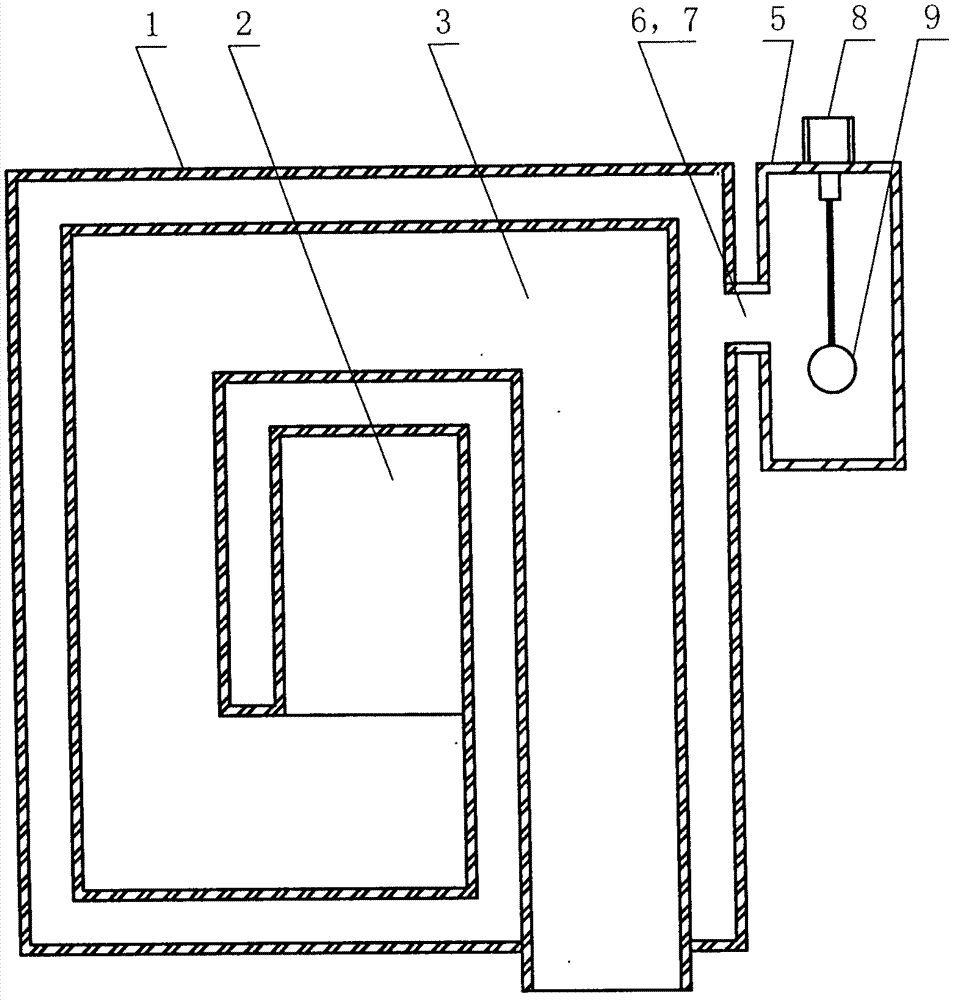

[0020] refer to figure 1 , 2 3. In this embodiment, this system is used in a multi-functional cooking unit to describe in detail the steam-hot water automatic conversion system of the present invention.

[0021]The multifunctional cooking unit system includes: heat absorber, automatic water replenishment water tank 5, movable fire-breathing stove 10, rice steaming cabinet 11, high water tank 12, low water tank 13, and connecting pipeline and electric control system 19. The position of the high water tank 12 is higher than the top of the heat absorber, generally at least 1-1.5m higher, and the position of the low water tank 13 is lower than the bottom of the heat absorber. The heat absorber includes a sealed water tank 1 with a square cross-section. The water tank is designed to control the water volume to no more than 30kg. There is a fire inlet 2 at the center of the bottom of the water tank. The fire inlet connects to the flue 3 hovering in the sealed water tank. The flue 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com