A method for forming nitrogen foam surface for oil and gas well fracturing

A technology of nitrogen foam and oil and gas wells, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., which can solve the problems of inability to produce uniform and stable foam safely and efficiently, and reduce formation damage and pressure resistance Strong, wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

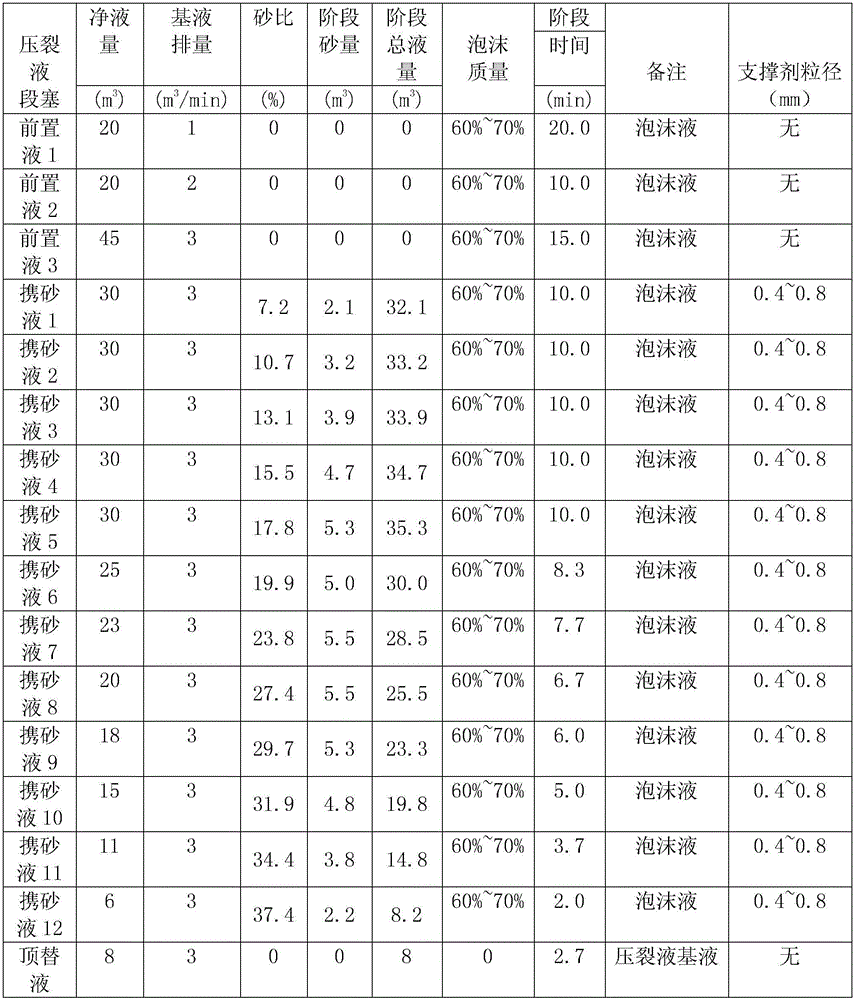

Embodiment 1

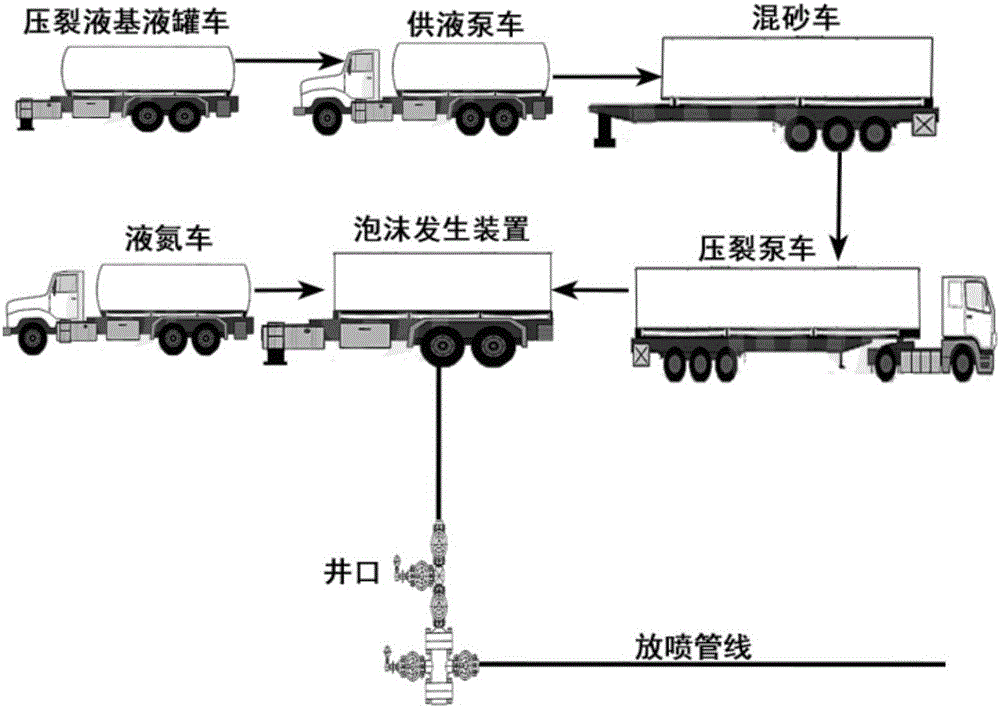

[0030] A method for forming nitrogen foam on the ground for oil and gas well fracturing. The implementation process of the method is applied to the ground equipment required for the fracturing process: liquid nitrogen truck, fracturing liquid base liquid tank truck, liquid supply pump truck, sand mixing truck, press Crack pump truck, foam generating device;

[0031] The method includes steps as follows:

[0032] (1) Arranging and connecting construction vehicles and fracturing equipment: connecting the fracturing liquid-based liquid tank truck, liquid supply pump truck, sand mixing truck, fracturing pump truck, foam generating device and wellhead in sequence, and the liquid nitrogen truck is connected to Foam generating device;

[0033] (2) Pressure test: close the wellhead valve, use the highest pressure value designed for oil and gas well fracturing to suppress the pressure of the construction vehicle and fracturing equipment described in step (1), and keep it for 10 to 20 ...

Embodiment 2

[0040] A method for forming a nitrogen foam surface for oil and gas well fracturing as described in Example 1, the difference is that the proppant particle in the step (4) is ceramsite or quartz sand, and its particle size is 0.15 to 0.3 mm.

Embodiment 3

[0042]A method for forming a nitrogen foam surface for oil and gas well fracturing as described in Example 1, the difference is that the proppant particle in the step (4) is ceramsite or quartz sand, and its particle size is 0.8 to 1.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com