Adjustable check bar component and using method

An adjustable, rod-checking technology, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve problems such as temperature rise, cost increase, bearing seat hole axis and concentric check rod axis error, etc., to reduce production costs, Easy disassembly and assembly, meeting the installation accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

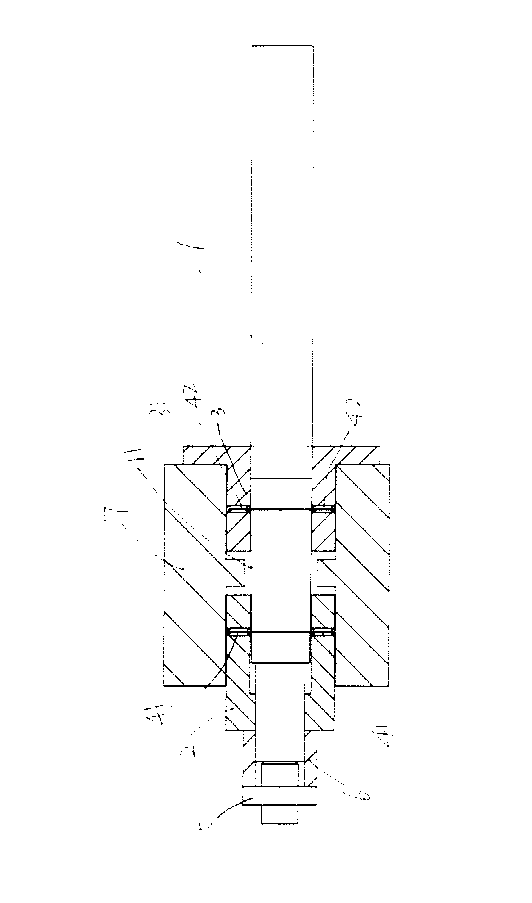

[0034] see figure 1 As shown, an adjustable detection rod assembly includes a detection rod 1 with a conical side surface 11, a first positioning sleeve 2, a second positioning sleeve 3, a first positioning rod 41, a second positioning rod 42, and a nut 5 , the taper of the conical side surface 11 is 1:50, the detection rod 1 is provided with an external thread on the surface near the conical top end, the nut 5 can be screwed on the external thread at one end of the detection rod 1, and the nut 5 can directly touch the The first positioning sleeve 2 or the second positioning sleeve 3 is pressed tightly or indirectly through the spacer 6 . Both the first positioning sleeve 2 and the second positioning sleeve 3 can be sleeved on the inspection rod 1 and can slide along the axial direction of the inspection rod 1 at the same time, and one end surface of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com