Micromechanical gyroscope drive method

A technology of a micromachined gyroscope and a driving method, which is applied in the direction of gyroscopic effect for speed measurement, gyroscope/steering sensing equipment, measuring device, etc. System instability and other problems to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

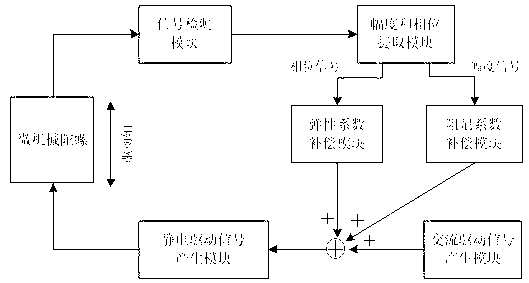

[0019] Such as figure 1 As shown, the steps of the micromachined gyroscope driving method are as follows:

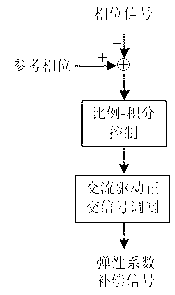

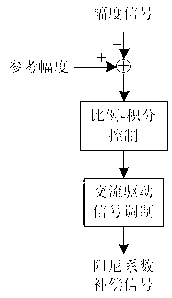

[0020] 1) Generate two mutually orthogonal signals through the AC drive signal generation module, and use one of them as the AC drive signal, generate the elastic coefficient compensation signal through the elastic coefficient compensation module, and generate the damping coefficient compensation signal through the damping coefficient compensation module. The AC drive signal, the elastic coefficient compensation signal and the damping coefficient compensation signal are added together and then input as an AC signal to the electrostatic drive signal generation module. The generation of two mutually orthogonal signals can be implemented through a coordinate rotation digital computer algorithm or It is realized by methods such as direct digital frequency synthesis;

[0021] 2) The electrostatic driving signal generation module generates an electrostatic driving signal acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com