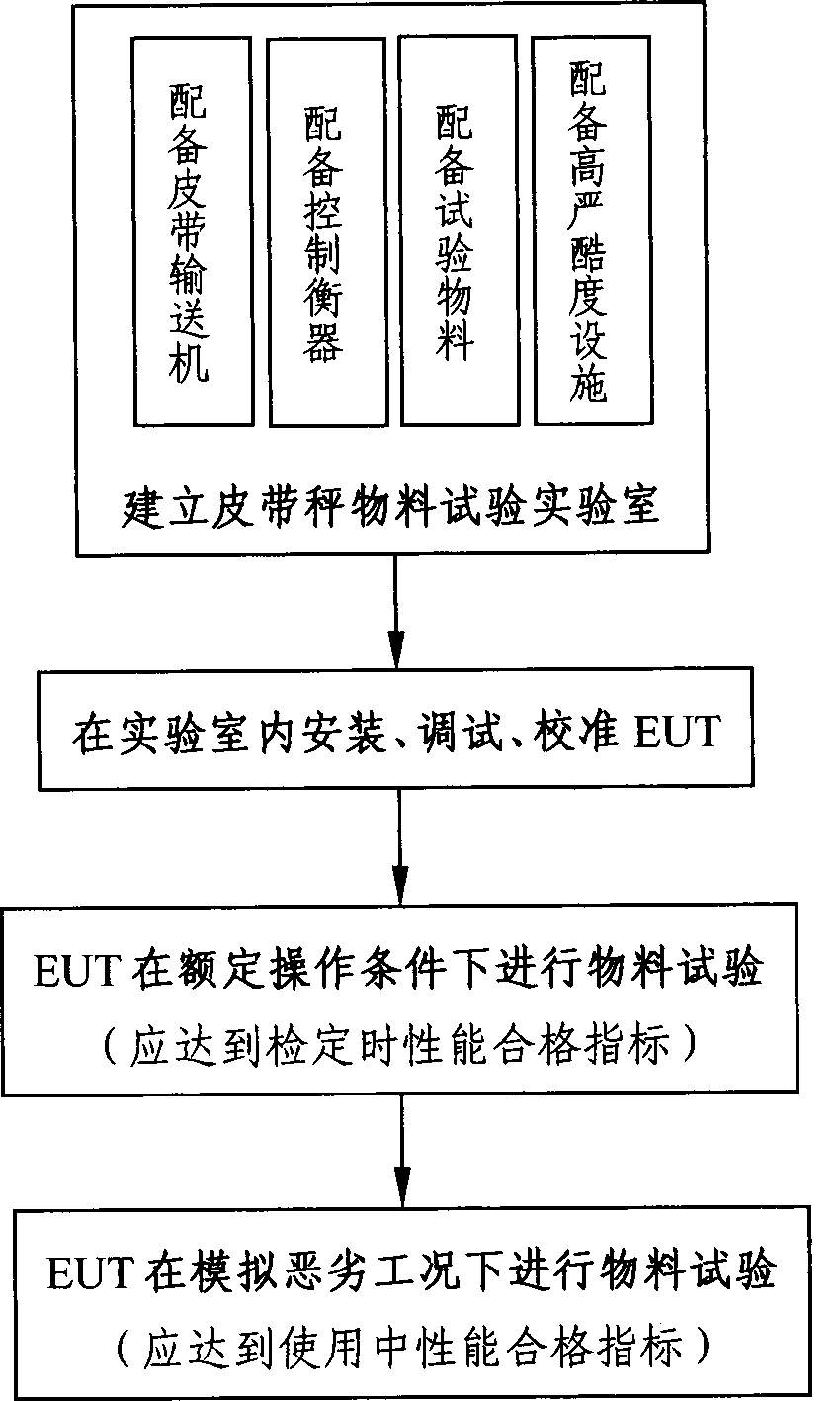

Durability test method

A technology of durability test and test items, applied in the field of durability test, it can solve problems such as affecting the normal use of users, difficult to control the weighing instrument, and unable to provide measurement data stably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

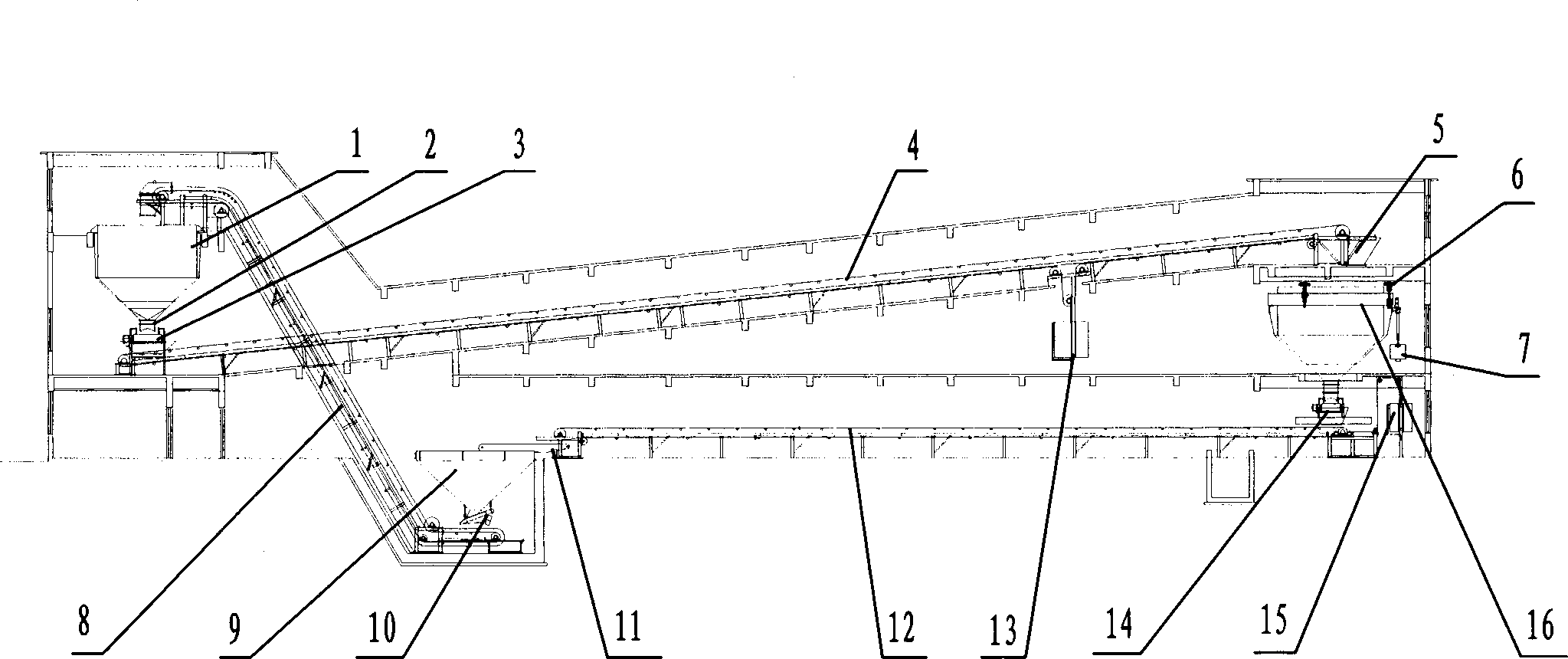

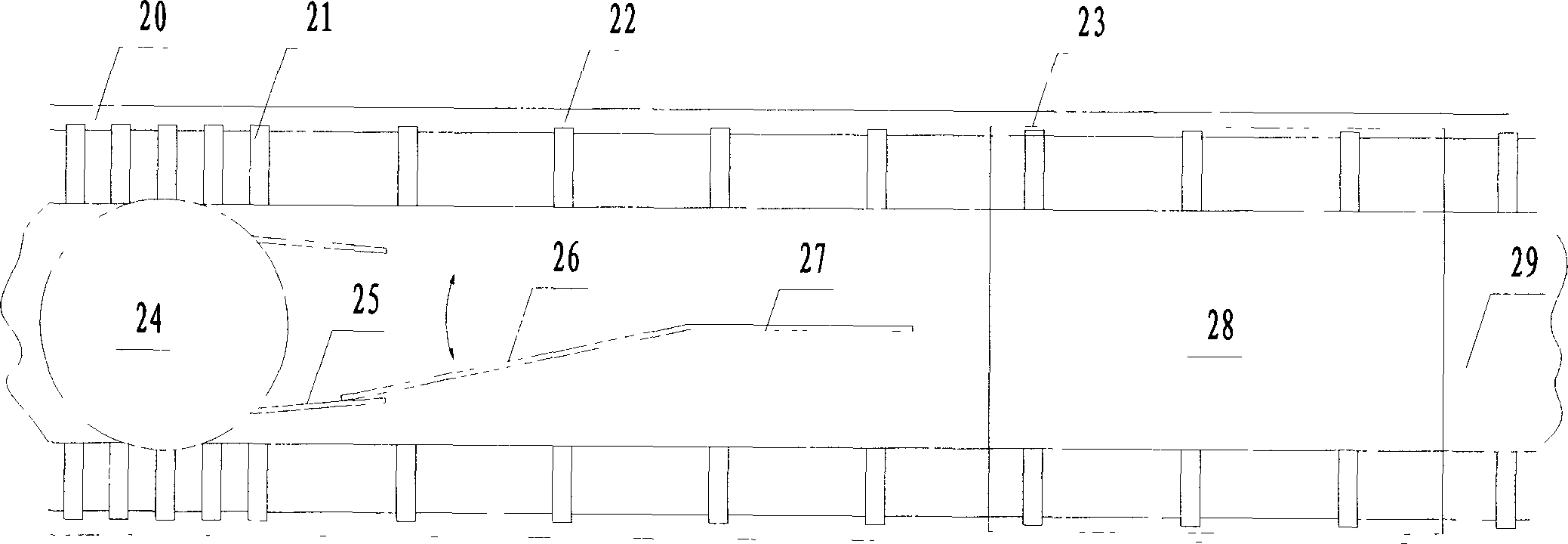

[0018] The external factors involved in the durability test method mentioned below are limited to "conveyor and working conditions", and the durability test example is carried out in the "Jiangsu Province Dynamic Weighing Engineering Technology Research Center". The center is a three-story building with 4 long belt conveyors inside, such as figure 2 As shown, wherein: the bottom layer is equipped with a belt conveyor with a width of 650mm and a length of 800mm, represented by a mark 12, and its belt tension adjustment device is a trolley towed by the gravity of the water tank 15, which is also installed on the bottom layer; and a belt conveyor with a width of 1000mm and a length of 1200mm Each belt conveyor is represented by mark 4, and their feed end is on the second floor, and the discharge end is on the third floor, and their belt tension regulators are installed on the second floor as the water tank 13 of the weight. The hopper scale 16 is used as a control weighing instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com