Spring operating mechanism

A technology of operating mechanism and closing spring, which is applied to the power device inside the switch, high-voltage air circuit breaker, electrical components, etc., can solve the problems of sudden closing of the circuit breaker, lack of closing protection, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

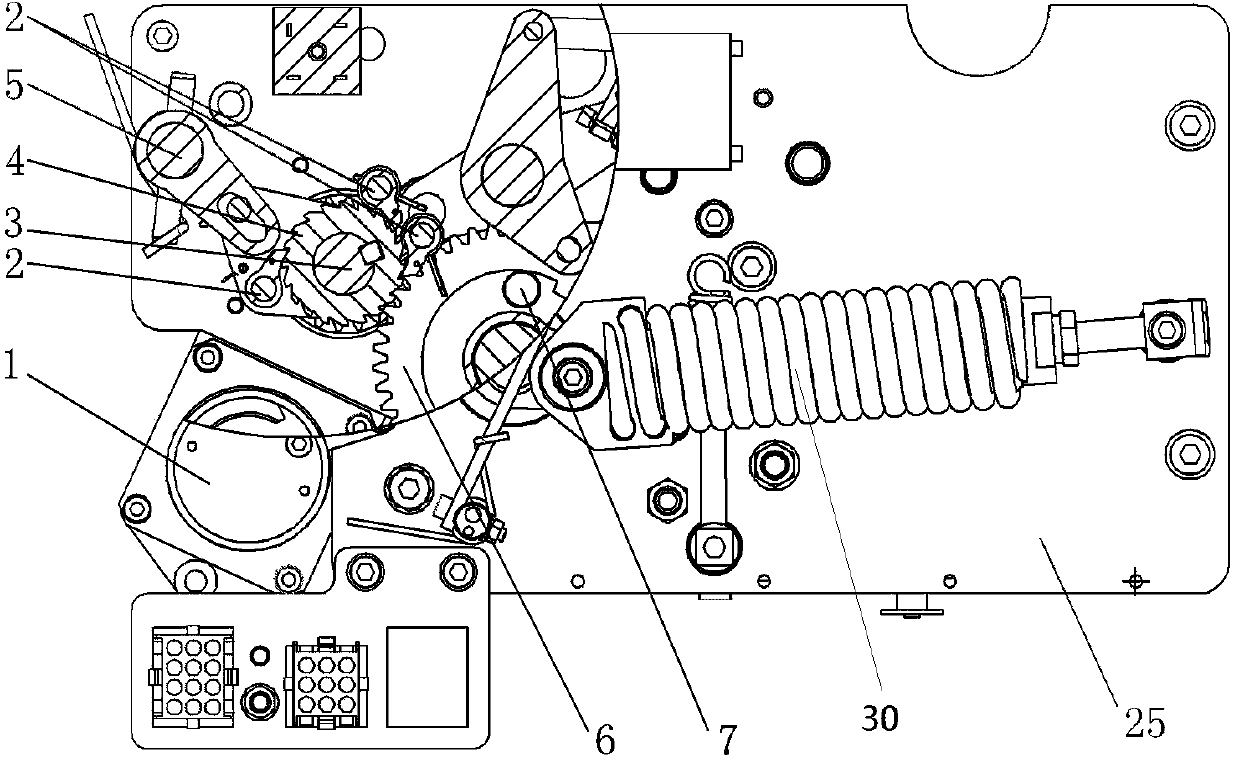

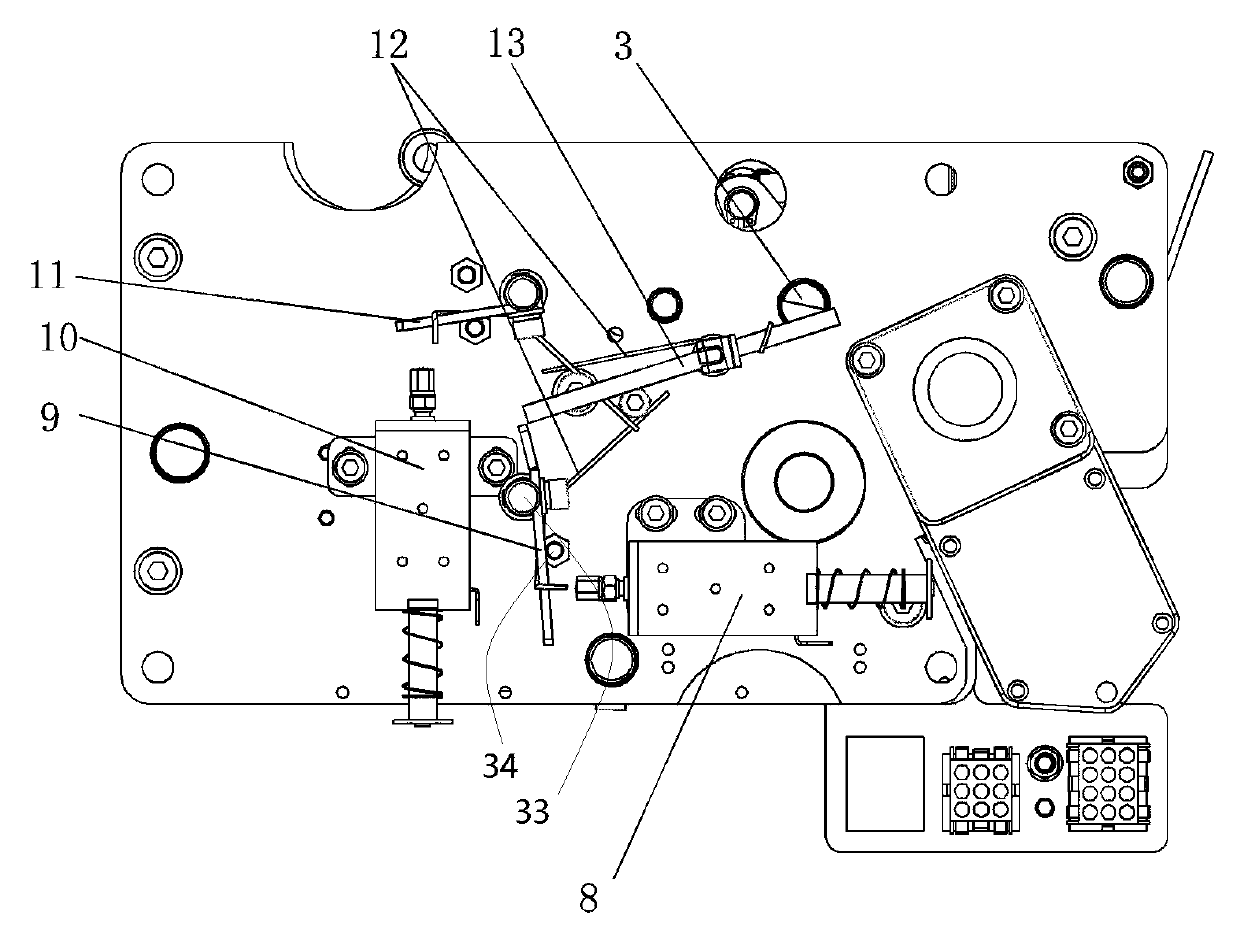

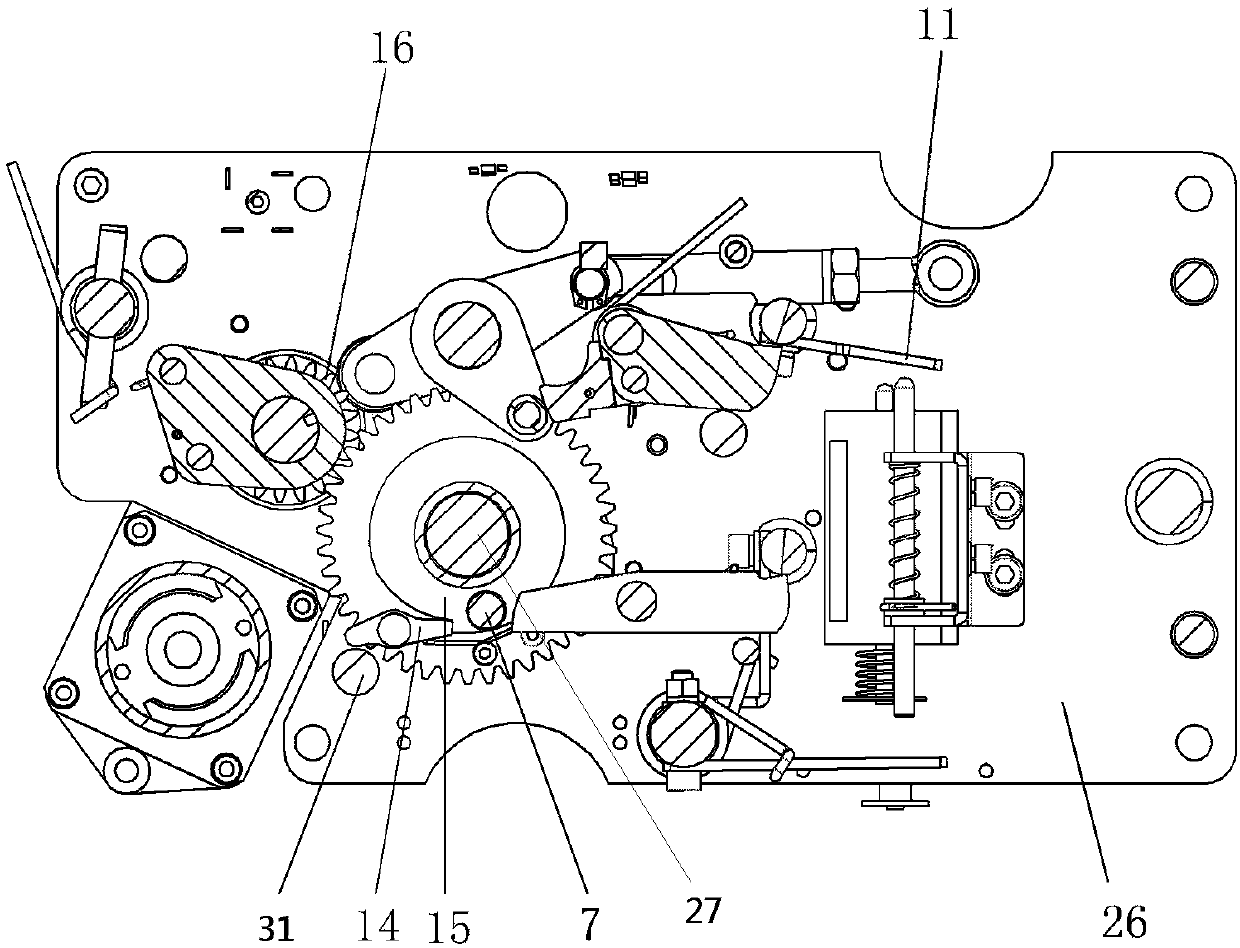

[0023] An embodiment of a spring operating mechanism such as Figure 1~5 As shown, it includes a frame, and the frame includes a front mounting plate 25 and a rear mounting plate 26 arranged side by side at intervals, and an input shaft 3, a transmission shaft, an energy storage shaft 27 and a closing half shaft 33 are rotated on the frame, and the input shaft 3 A reversing gear 16 is arranged on it, and the spring operating mechanism also includes a ratchet and a pawl mechanism. The ratchet and pawl mechanism include a ratchet 4 arranged on the reversing shaft 3 and three ratchets 2 arranged on the periphery of the ratchet 4 . The frame is provided with an energy storage motor 1 and a manual energy storage structure 5 that are connected to the input shaft 3 in transmission to input torque to the input shaft 3, and the energy storage motor 1 and the manual energy storage structure 5 can be used separately. The transmission shaft is provided with a transmission gear 6 meshing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com