A heat sink shared by multiple chips and a circuit board provided with the heat sink

A circuit board and heat sink technology, applied in the field of communication, can solve problems such as limited improvement of heat dissipation capacity, creep of chip solder joints, and limited heat dissipation area, so as to improve heat dissipation capacity, avoid solder joint creep, and controllable force on chips Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

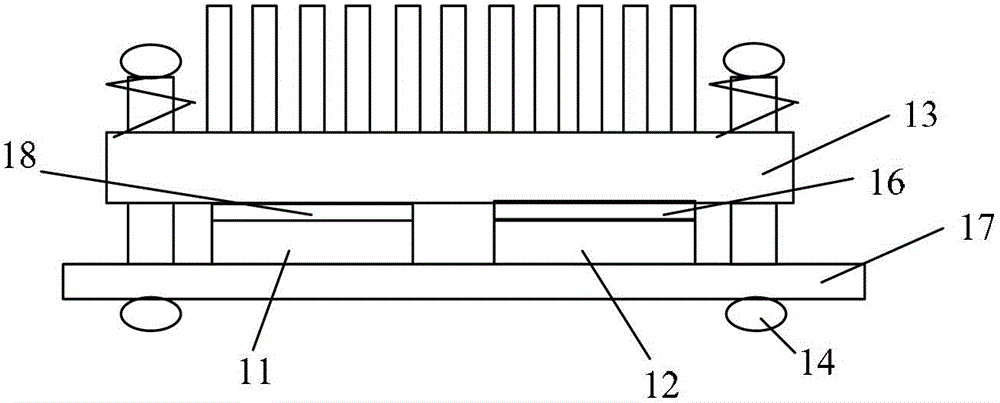

[0016] In each embodiment of the present invention, the lower surface of the heat sink substrate, that is, the side closest to the chip is provided with a plurality of bosses. For chips with a small chip height tolerance on the circuit board, according to the difference in the height of the bosses, Match chips of different heights; and add limit brackets on the radiator to provide support for the radiator to be placed on the circuit board, thereby controlling the pressure on the chip and avoiding excessive force on the chip and causing it to be placed on the circuit board. The creep of the upper solder joints is realized, and multiple chips share a heat sink to increase the heat dissipation area.

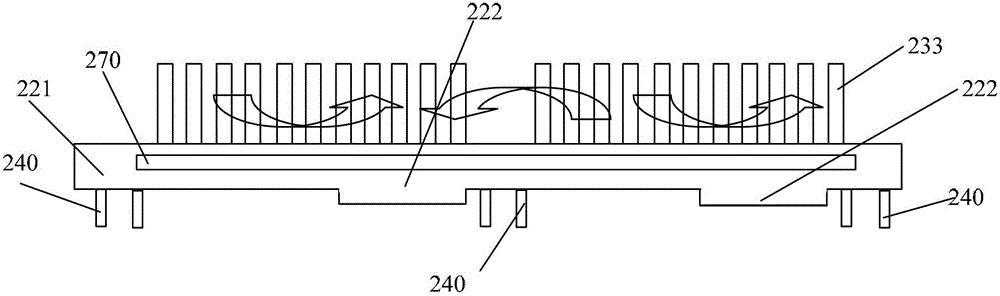

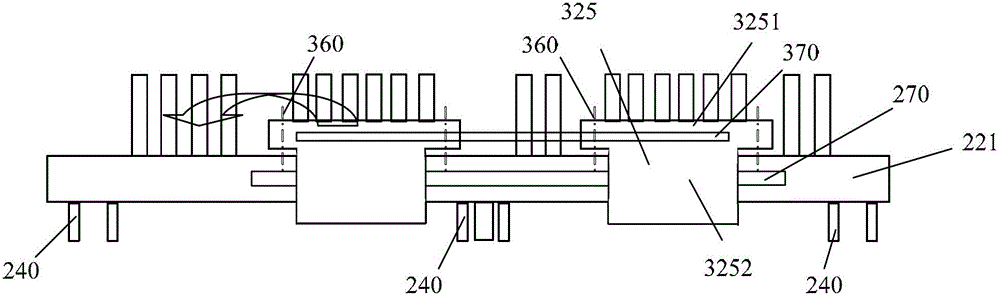

[0017] figure 2 It is a structural schematic diagram of an embodiment of the radiator of the present invention. Such as figure 2 As shown, the heat sink shared by multiple chips includes: a base plate 221, and a plurality of heat dissipation fins 233 are arranged on the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com