Rope ladder headstock

A technology of ladder head frame and pulley block, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of high labor intensity, and achieve the effect of solving the problem of high labor intensity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

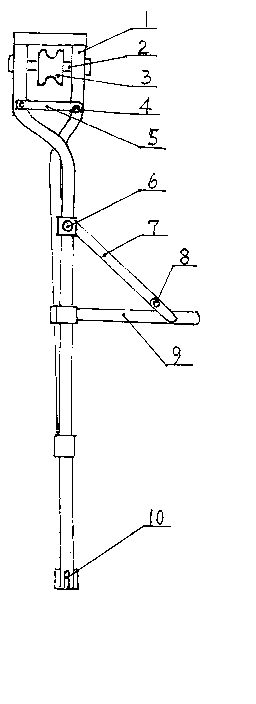

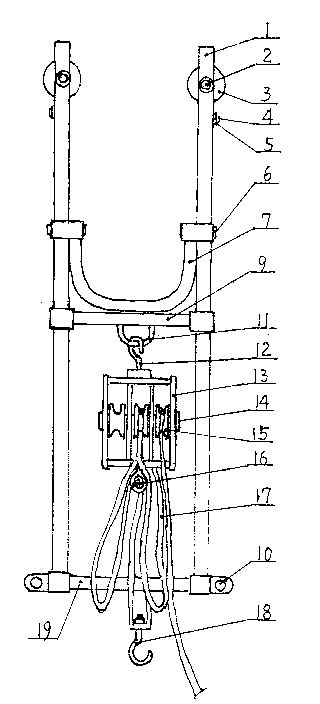

[0010] Examples, see attached figure 1 , 2 , the upper ends of the two parallel main frames 1 of the soft ladder head frame are equipped with two pulleys 3 with a pulley shaft 2, a baffle 5 is movably installed on the outer side of the main frame 1 below the pulley 3, and the other end of the baffle 5 is equipped with a baffle pin 4 Fixed limit. In the middle of the main frame 1 on both sides, a semi-annular seat ring 7 is movably installed with the seat ring pin 6, the seat ring 7 is connected with the seat 9 by the seat ring connecting pin 8, and the seat 9 is fixedly mounted on the seat block Below the ring 7, in the middle of the two parallel main frames 1. A pulley block frame hanging ring 11 is fixed under the rear beam of the seat 9 , a pulley block frame hook 12 is fixed above the pulley block frame 13 , and the pulley block frame 13 is hung on the pulley block hanger ring 11 with the pulley block frame hook 12 . On the pulley block frame 13, three pulleys are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com