Ventilation nozzle and plastic film stretching system having associated ventilation nozzle

A technology for ventilation nozzles and nozzle outlets, applied in the field of plastic film stretching equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

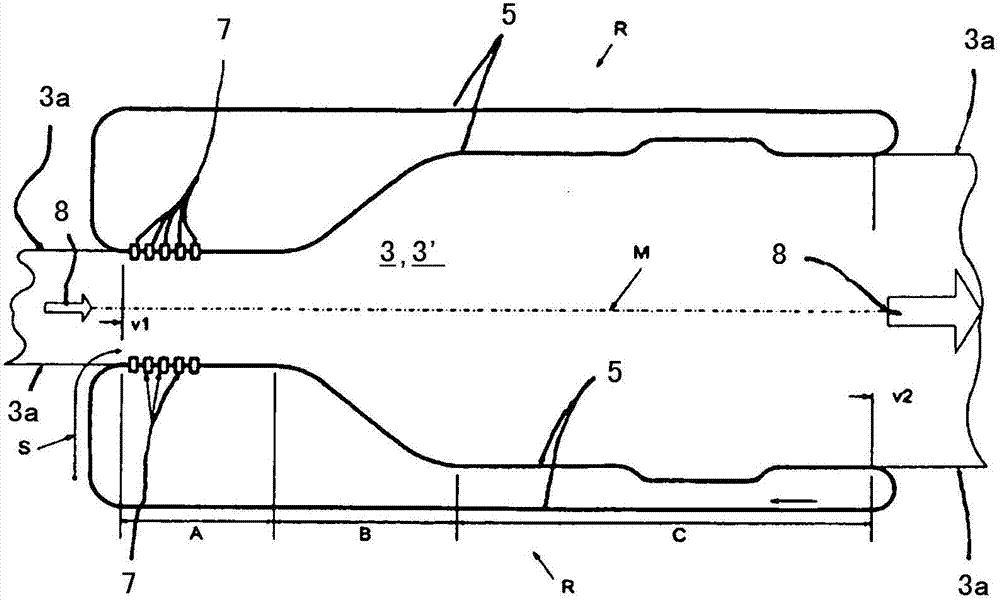

[0035] figure 1 shows schematically the basic construction of a plant for processing web-like material, more precisely a plastic film stretching plant. In this plastic film stretching device, the material web 3', more precisely the plastic film 3, is stretched continuously in the transverse direction or simultaneously in the longitudinal and transverse directions.

[0036] For this, a vertical plane or symmetry plane M (perpendicular to figure 1 The plane of the illustration in ) provides two closed, circumferential tong rails 5 on which the tongs 7 can be looped. exist figure 1 Several clamps 7 are shown in . Here, the plastic film is conveyed through the device coming from the left, wherein the circumferential grippers 7 clamp the film 3 opposite each other at the edge 3a of the material web, that is to say at the edge 3a of the plastic film, and make the Its motion moves through the device. After heating zone A, the clamps are separated from each other in a V-shape in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com