A cam-type continuously variable transmission method and transmission

A continuously variable speed and cam-type technology, which is applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as low load-carrying capacity, poor resistance to overload and impact resistance, and high requirements for parts processing and lubrication. Efficiently balanced speed and power output, guaranteed continuity and stability, continuous subtle stepless modulation and balanced output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

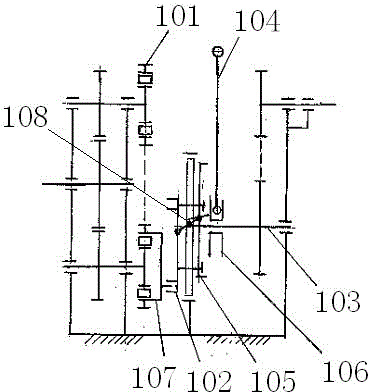

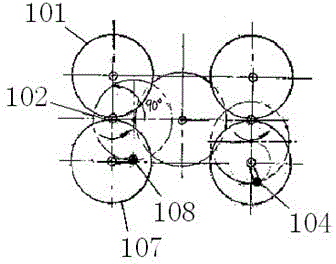

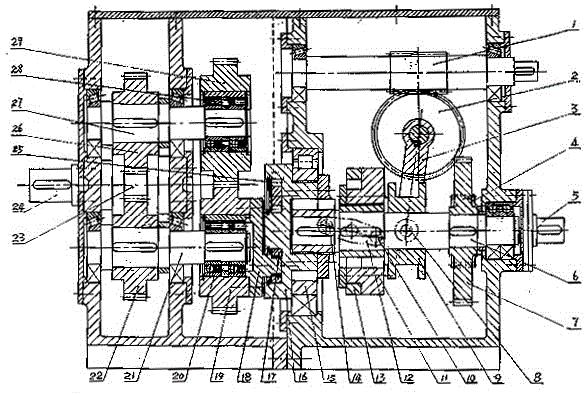

[0042] Such as Figure 1 to Figure 5 Shown is an adjustable eccentric end face circular groove cam type CVT according to the present invention, which includes a casing, an input shaft 5 is installed on the casing, a gear 4 is tightly mounted on the input shaft 5, and the gear 4 is tightly mounted on the gear The gear 7 on the main shaft 6 is meshed, and the power is transmitted to the gear main shaft 6, which is tightly mounted on the gear main shaft 6. The cam disc installation flange 15 is also tightly installed on the gear main shaft 6, and the end surface circular groove cam 16 is installed on the cam disc installation flange 15. And it can slide radially along the radial hole groove on the cam disc installation flange 15; The circular groove on the end face drives the roller 25, the finger ring 17 and the crank finger plate 18, and the crank finger plate 18 drives the ring gears 19, 29 tightly mounted on the one-way bearings (one-way overrunning clutches) 20, 28 along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com