Solenoid valve, and method for producing such solenoid valve

A solenoid valve and valve needle technology, applied in the field of manufacturing solenoid valves, can solve the problems of high production costs and achieve the effect of eliminating chip processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

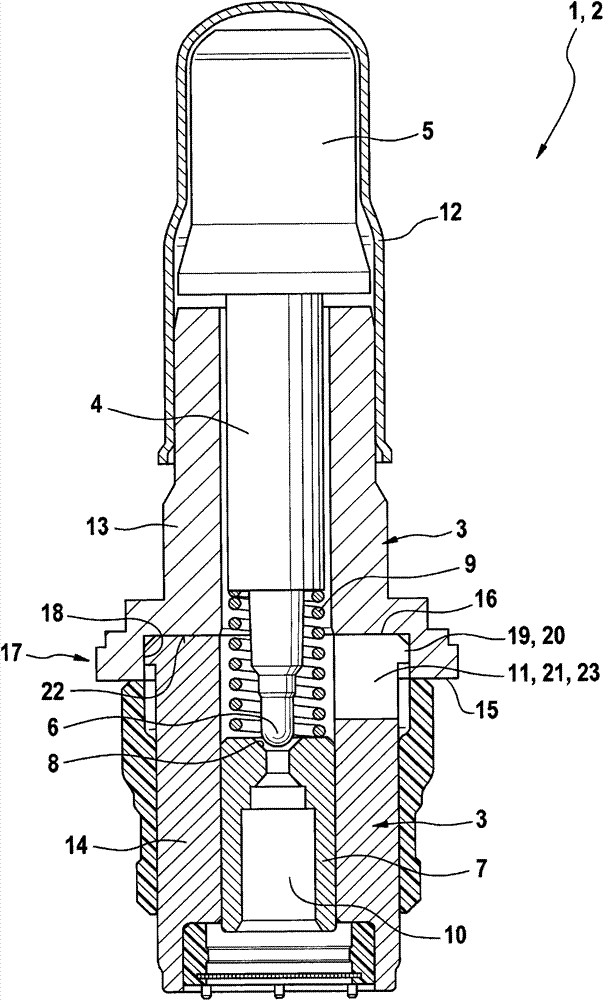

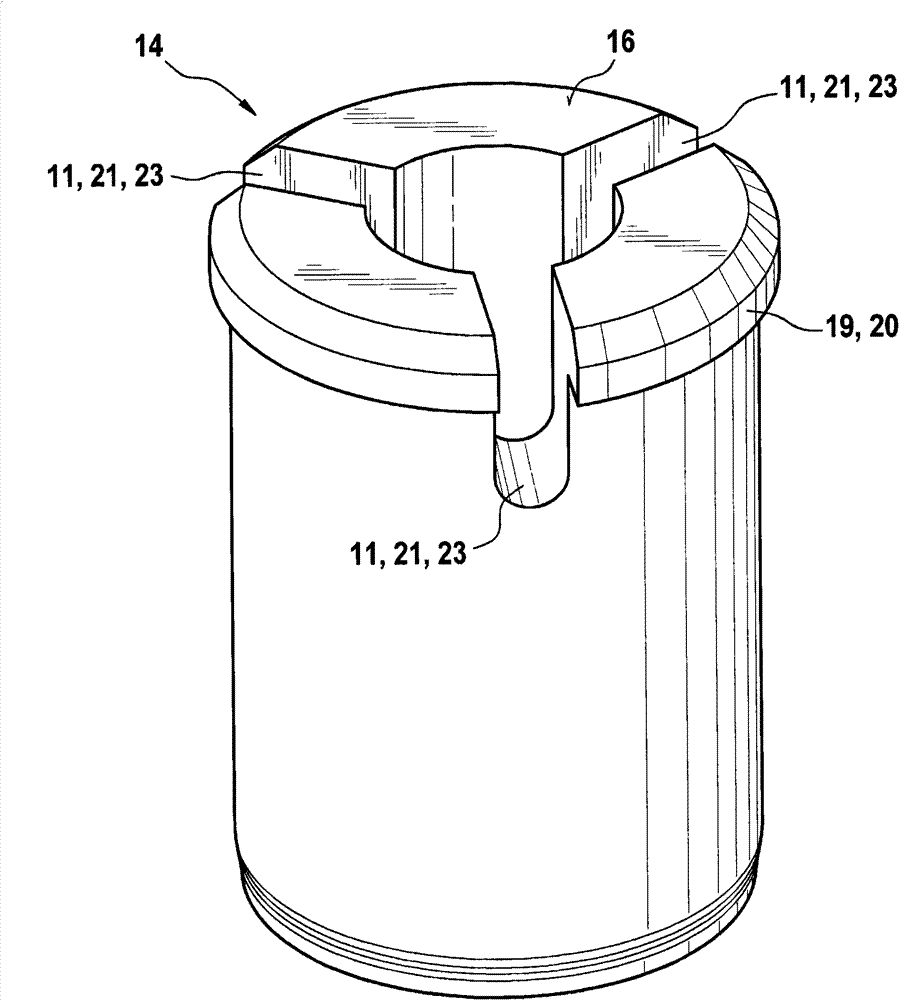

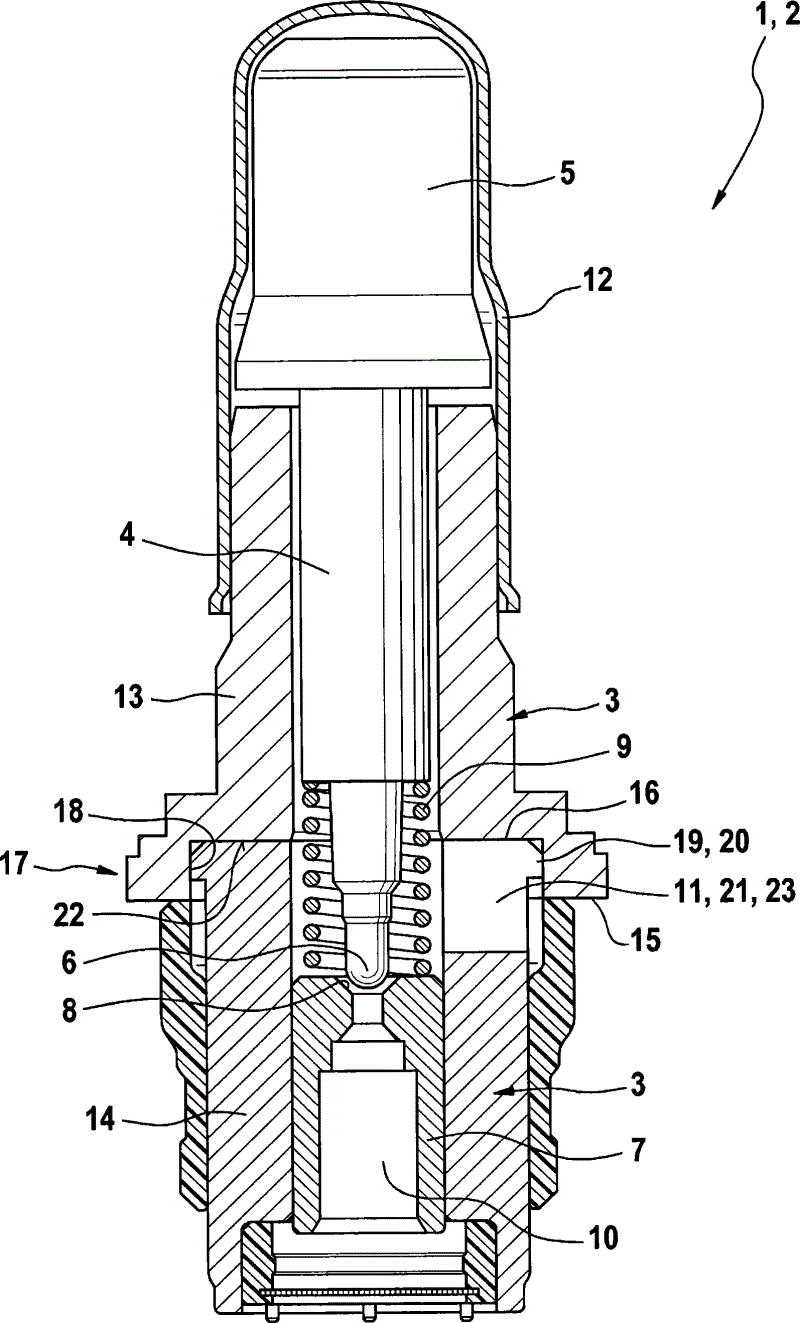

[0016] figure 1 Shown is a simplified longitudinal sectional view of the solenoid valve 1 . The solenoid valve 1 is a so-called de-energized open valve 2 which is used in a hydraulic system of a motor vehicle, in particular in a braking system such as an ESP system, an ABS system or a TSC system. The solenoid valve 1 has a core sleeve 3 in which a valve needle 4 is arranged displaceable in the longitudinal direction or axially. The valve needle 4 has an armature 5 at its end opposite its valve tip. The valve needle interacts via its valve tip 6 with a valve seat 8 formed in a valve body 7 fixed in the core sleeve 3 . One end of the coil spring 9 is close to the valve body 7, and the other end is close to the axial stop of the valve needle 4. The coil spring presses the valve needle 4 away from the valve seat 8, so that when the solenoid valve 1 is not operated Open the flow cross section in the state. When the solenoid valve 1 is opened, fluid can flow in through the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com