Power transmission device

A power transmission device, the technology of left and right, applied in the direction of transmission device, multi-gear ratio transmission device, differential transmission device, etc., can solve the problem of reducing the control accuracy of the engagement force, and achieve the effect of preventing mutual interference between actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

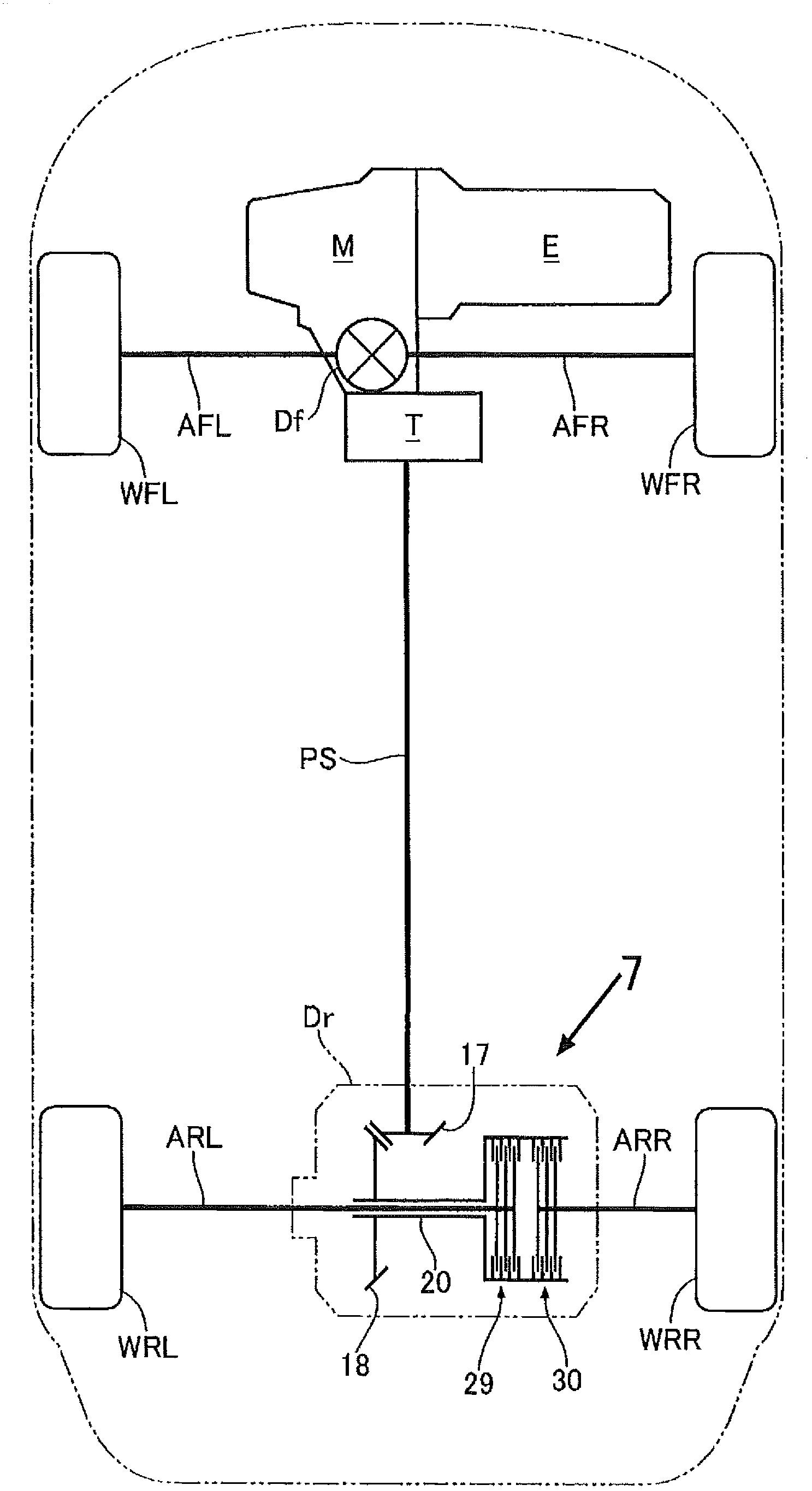

[0036] Such as figure 1As shown, a four-wheel-drive vehicle based on a front-engine / front-drive vehicle includes: front wheels WFL and WFR as main drive wheels, and the driving force of the engine E passes through the transmission M, the front differential gear Df, and the left and right axles AFL , AFR and transmitted to the main drive wheels; part of the driving force of the rear wheels WRL, WRR, front wheels WFL, WFR as auxiliary drive wheels is transmitted through the transmitter T, the propeller shaft PS, the rear differential gear Dr and the left and right axles ARL , ARR and transmitted to the secondary drive wheel.

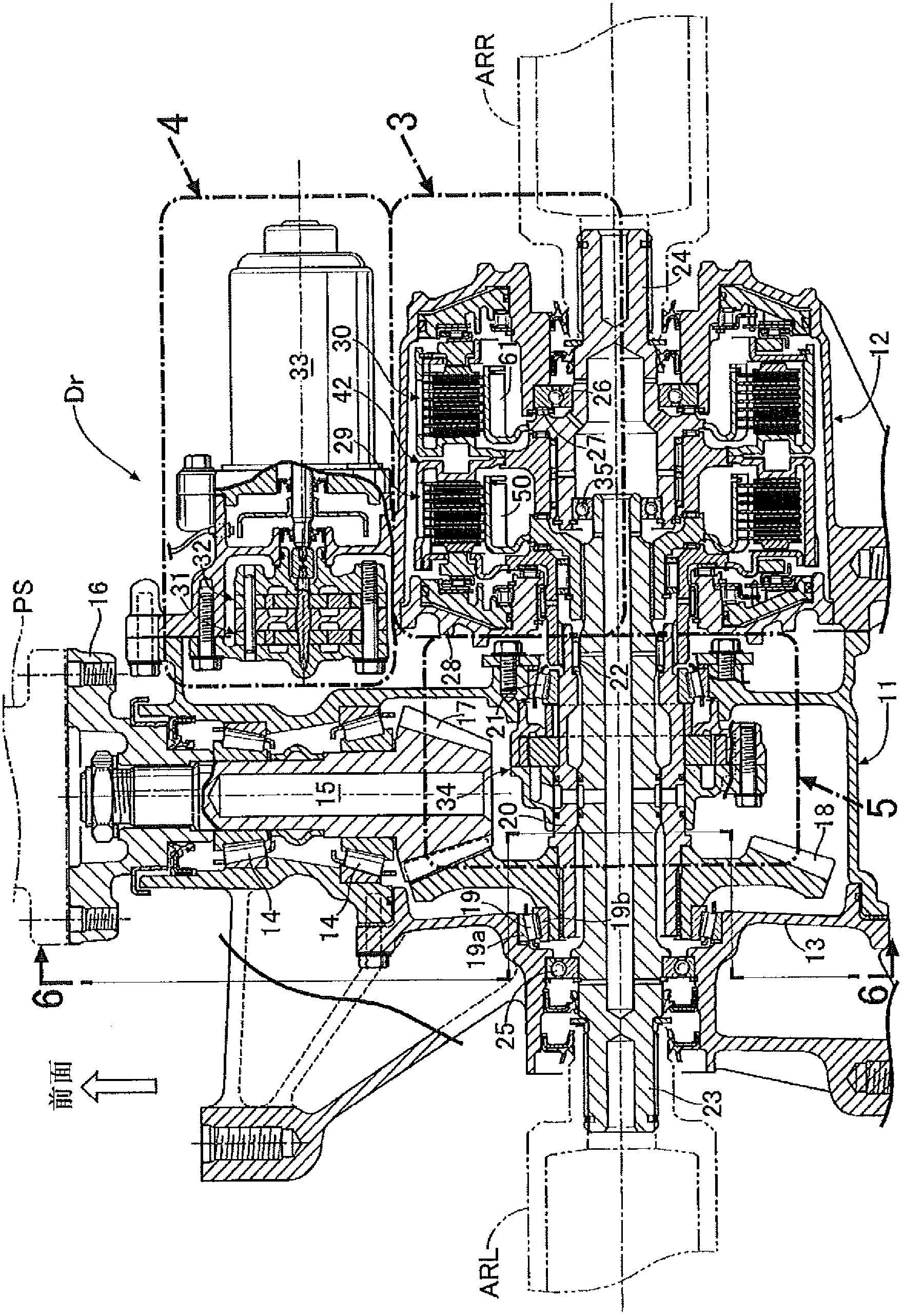

[0037] Such as figure 2 As shown, the rear differential gear Dr includes a center case 11 , a side case 12 joined to the right side of the center case 11 , and a side cover 13 joined to the left side of the center case 11 . The input shaft 15 extending in the front-rear direction of the vehicle body is rotatably supported by the center casing 11 via two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com