Heat exchanger for thermoelectric generators

A technology of thermoelectric generators and heat exchangers, applied in heat exchange equipment, thermoelectric devices that only use the Peltier or Seebeck effect, heat sinks, etc., can solve the problems that hinder the effective use of exhaust gas energy, differential heat transfer coefficient, etc., and achieve improvement Energy efficiency, homogenization, and reduction of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

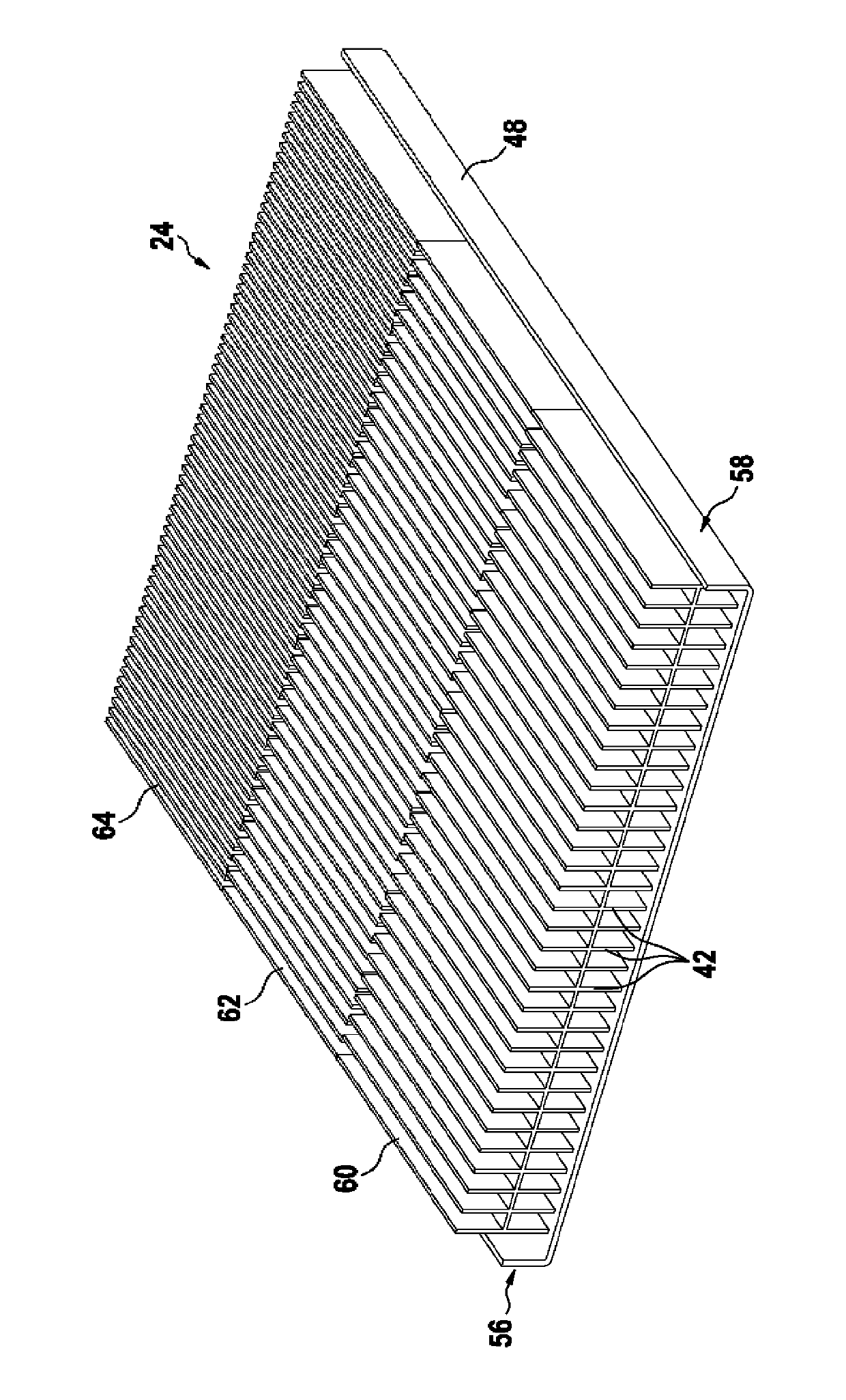

[0026] figure 1 A possible configuration of a heat exchanger with ribbed heat channels and three columns of thermoelectric generators (TEGs) along the flow direction is shown.

[0027] In a possible embodiment, the heat exchanger 10 can have two channels 12 , 14 for the cooling medium 16 as a heat sink. In this case, the one channel 12 for the cooling medium 16 runs on the bottom side 18 of the heat exchanger 10 , and the second channel 14 for the cooling medium 16 runs on the upper side 20 of the heat exchanger 10 .

[0028] An additional channel 24 serving as a heat source for a heating medium 26 is located in the middle 22 of the heat exchanger 10 .

[0029] The channels 12 , 14 for the cooling medium 16 and the channels 24 for the heating medium 26 extend in mutually parallel planes and form a stack 28 with a stack axis 30 here. Viewed along the stack axis 30 , the channels 12 , 14 for the cooling medium 16 and the channels 24 for the heating medium 26 are arranged alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com