Five-shaft moving-column-type numerically controlled milling machine

A CNC milling machine and column type technology, which is applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of poor bottom surface finish, increase processing cost, reduce processing accuracy, etc., achieve easy processing, improve production efficiency, and ensure The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

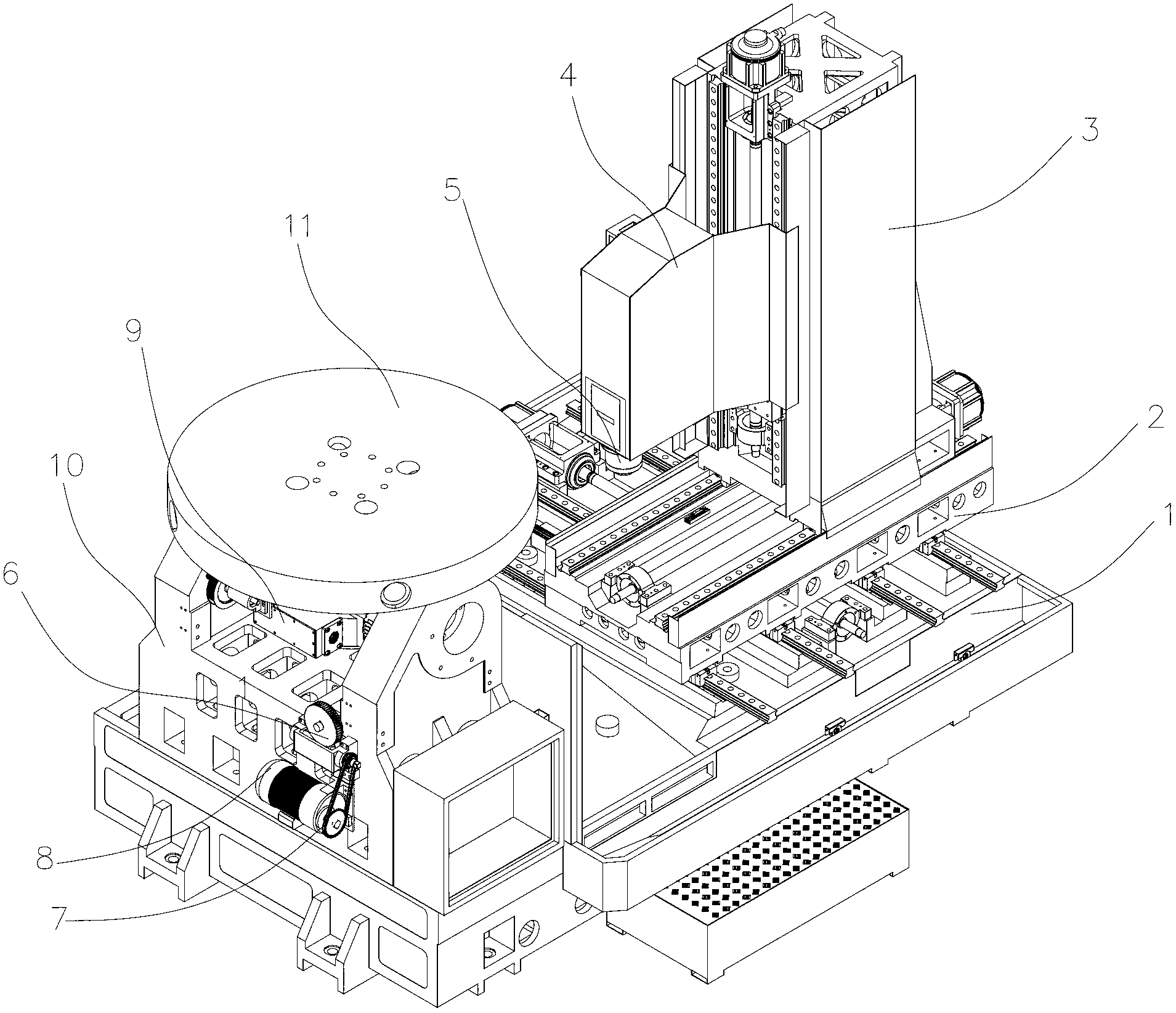

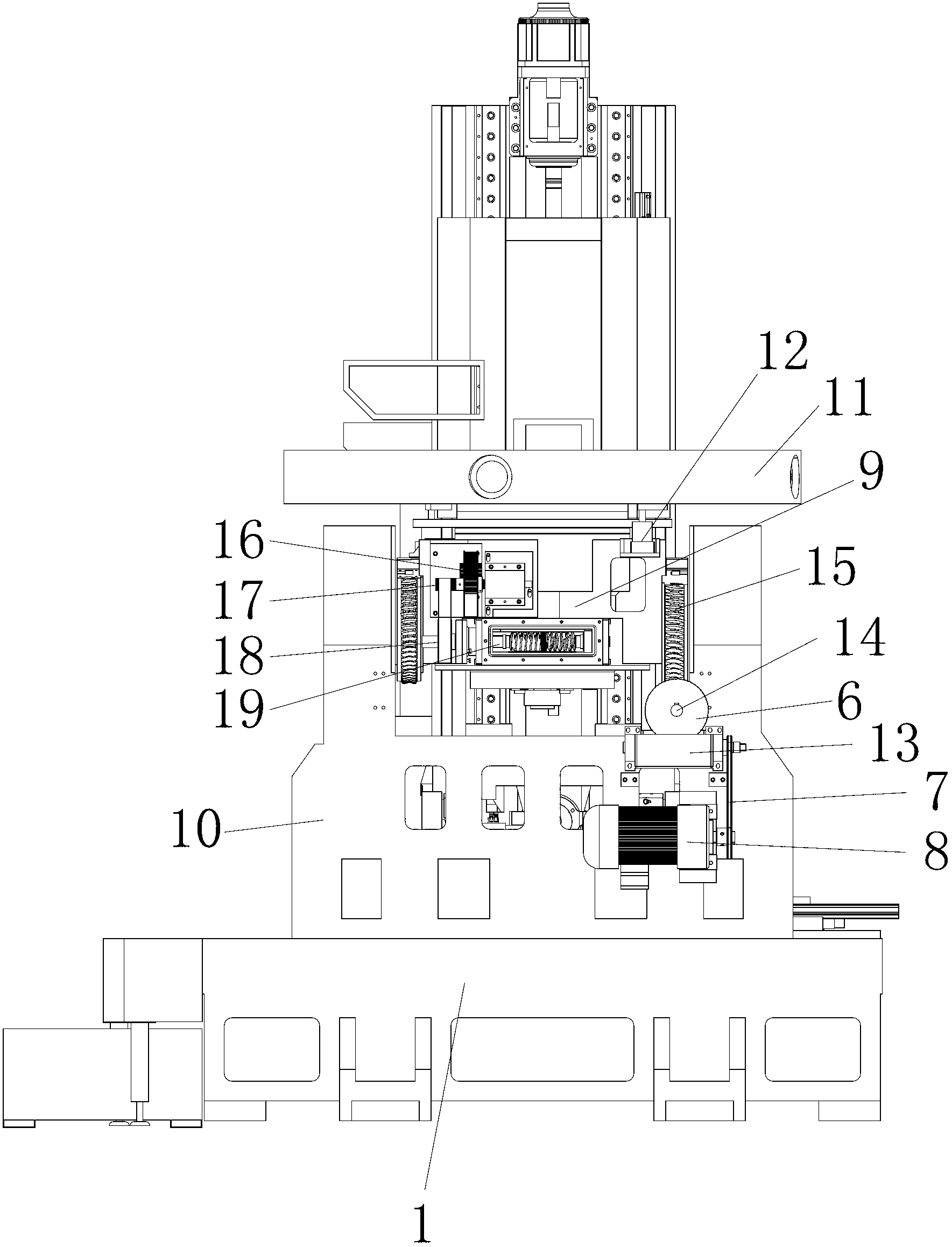

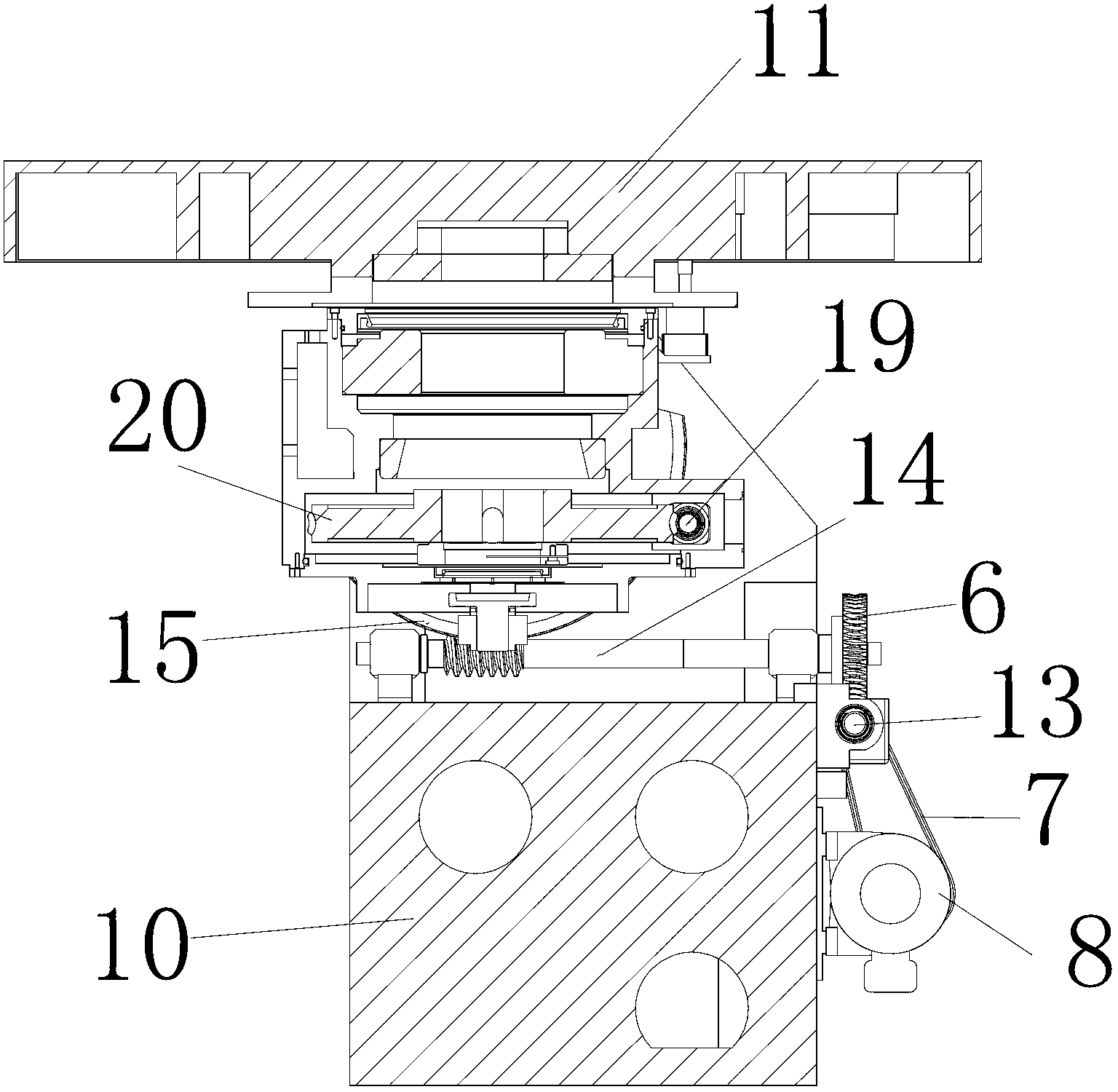

[0019] as attached Figure 1-4 Shown is a five-axis moving column CNC milling machine of the present invention, which includes a fully supported moving column main body, a self-locking index plate, and a base 1; the fully supported moving column main body is arranged on one side of the base 1 The fully supported moving column body includes a saddle 2 that is slidably connected with the upper surface of the base 1 and slides along the X-axis direction, and is slidably connected with the upper surface of the saddle 2 and moves along the Y-axis direction The sliding column 3, the head 4 which is arranged on the column 3 and can slide along the Z-axis direction, is arranged in the head 4 to rotate the main shaft 5; the self-locking index plate is arranged on the base 1 The other side of the self-locking index plate, including the index plate 11, up and down turning device, horizontal rotation device, clamp 12, index plate stand 10; the upper surface of the index plate 11 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com